Organic heat carrier boiler

A carrier and boiler technology, applied in the direction of heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large-scale power generation equipment that cannot realize capacity adjustment, electric power cannot be realized, and capacity surplus, etc., to achieve effective Conducive to grid load stability, better heat exchange effect, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

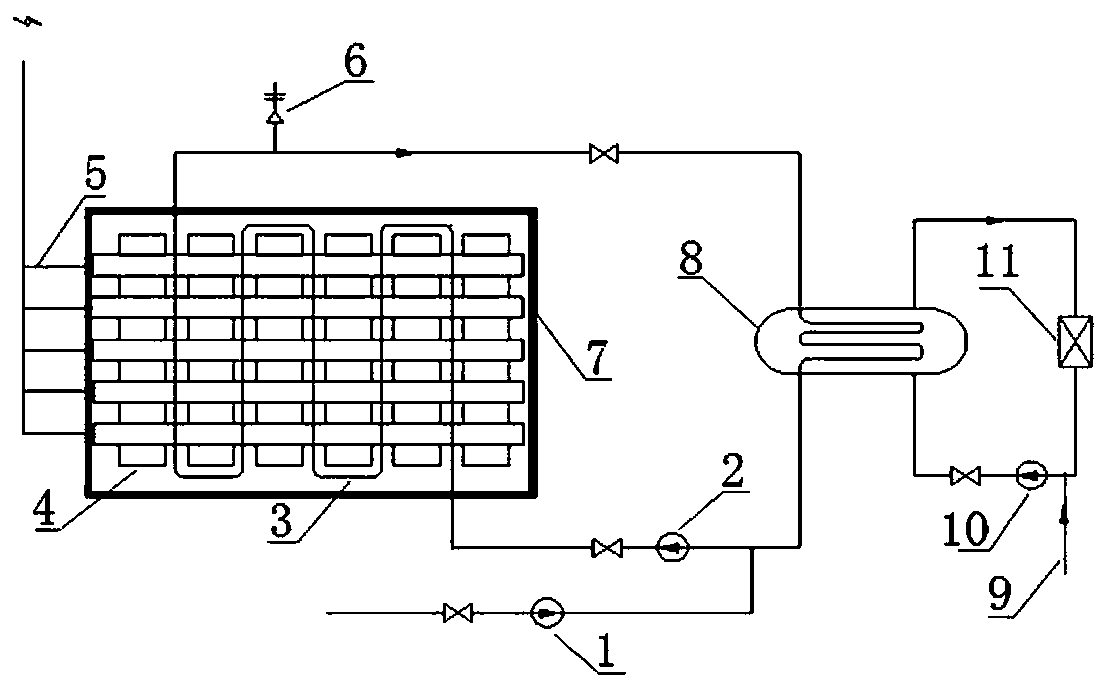

[0019] Such as figure 1 As shown, the organic heat carrier boiler includes solid heat storage device, high temperature oil pump circulation system and hot water circulation system. The high temperature oil pump circulation system includes oil injection pump 1, circulation oil pump 2, furnace tube 3 and safety valve 6. The S-shape is vertically arranged within the left and right intervals of the magnesia-iron brick heat storage stack 4, which is closely attached to the magnesia-iron heat storage brick. The heat transfer oil is introduced from the oil injection pump 1 to the high-temperature oil pump circulation system, and is guided from the circulation oil pump 2 to the furnace tube 3 The heat is received inside the furnace tube 3, and the heat transfer oil finally forms a path from bottom to top in the furnace tube 3, which first enters the lower heat storage unit. Due to the difference in temperature distribution between the upper and lower layers of the heat storage stack, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com