Pressure-bearing heat accumulation tank capable of containing heat accumulation material

A heat storage tank and heat storage technology, which is applied to heat storage equipment and central heating, can solve the problems of large area, large number of heat storage tanks, and small heat storage, so as to reduce the quantity and floor space and improve heat storage. Effect of temperature, quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

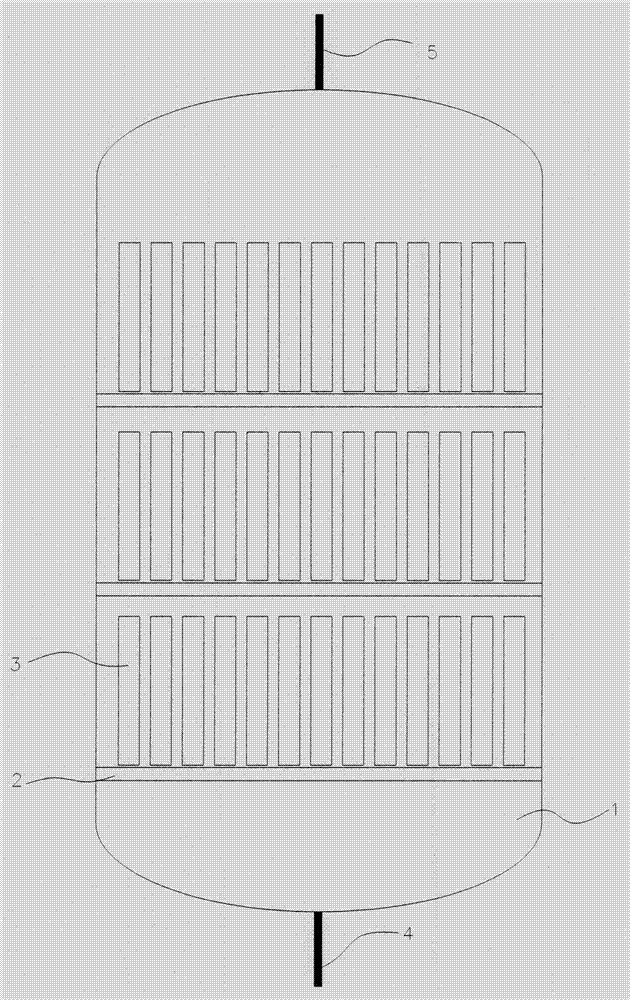

[0015] It can be seen from the accompanying drawings that this scheme consists of a heat storage tank 1, a tray 2, a heat storage plate 3, a lower water inlet and outlet 4 and an upper water inlet and outlet 5. This solution is to fix the tray 2 inside the heat storage tank 1, place the heat storage plate 3 on the tray 2, connect the lower water inlet and outlet pipe 4 to the lower part of the heat storage tank 1, and connect the upper water inlet and outlet pipe 5 to the upper part of the heat storage tank 1 , 1-5 form the heat storage tank that can adorn the heat storage material. In this specific embodiment, the tray 2 is installed inside the heat storage tank 1, the heat storage plate 3 hits the top of the tray 2, and the lower water inlet and outlet pipe 4 and the upper water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com