Self-moving device for cables of tunnel boring machine

A cable self-moving technology, which is applied in the direction of cable laying equipment, etc., can solve problems such as low efficiency, time-consuming stop and delivery, and inconvenient cable movement, so as to improve work efficiency, reduce safety hazards, and reduce manual care.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

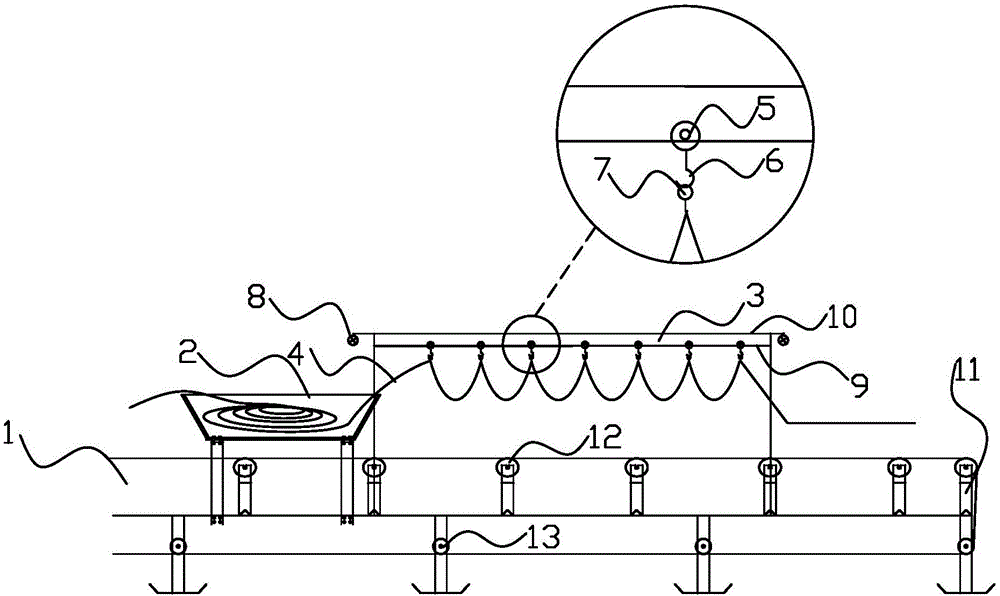

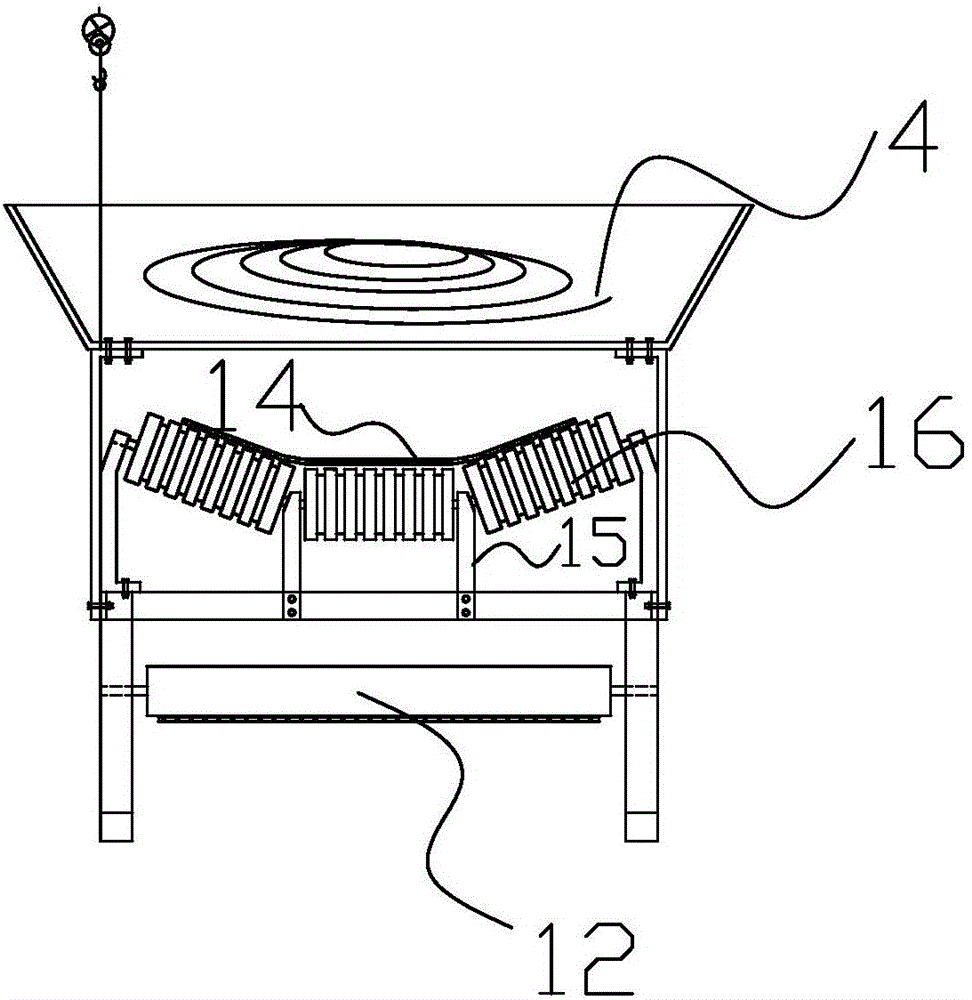

[0019] combine figure 1 , figure 2 : A fully-mechanized excavation cable self-moving device, related to cable 4, fully-mechanized excavation machine, belt conveyor tail buffer frame 11, the fully-mechanized excavation cable self-movement device includes a bottom bracket 1, a cable rack 2, a hook beam 3, and a bottom bracket 1 The upper end is fixed with a cable rack 2, and the other end is fixed with a hook beam 3. The cable 4 is placed around the cable rack 2. A sliding device 5 that can move along the horizontal direction is provided under the hook beam 3. Below the sliding device 5 A matching hook 6 is provided, the cable 4 passes through the hook 6 and is connected to the comprehensive excavator, and the front end of the bottom bracket 1 is rigidly connected to the tail buffer frame 11 of the belt conveyor.

[0020] Further, a steel wire rope 9 is also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com