Cable intermediate joint manufacturing method

A technology for intermediate joints and manufacturing methods, which is applied in the direction of cable joints, cable installation, equipment for connecting/terminating cables, etc., can solve the problems of poor waterproof and moisture-proof performance, and achieve good moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

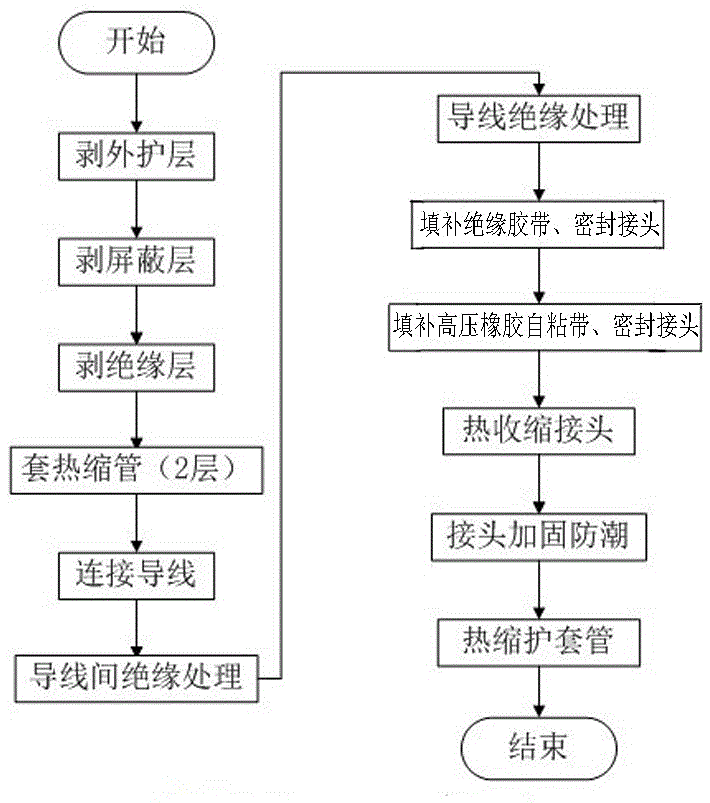

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] A specific embodiment of a manufacturing method of a cable intermediate joint of the present invention, as figure 1 As shown, a method for making a cable moisture-proof intermediate joint. This example is based on a YPY type φ8mm, 2*0.2mm cable. The specific method includes the following steps:

[0023] 1. Clean the cables, judge the stripping length of the two connectors according to the actual situation and strip them off (too long is a waste of material, too short is not easy to connect), the stripping length of the two cables here is about 30mm , to facilitate joint operation;

[0024] 2. Analog cables usually contain a shielding layer. Use a wire stripper to strip the insulation layer and the inner shielding layer of the two cables.

[0025] 3. Use wire strippers to peel off the cores of the two cables that need to be connected, and determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com