Fluid monitoring assembly with sensor functionality

A technology of sensors and sensor bases, applied in the direction of measuring instrument components, liquid/fluid solid measurement, equipment with stored calibration coefficients, etc., can solve problems such as increasing dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

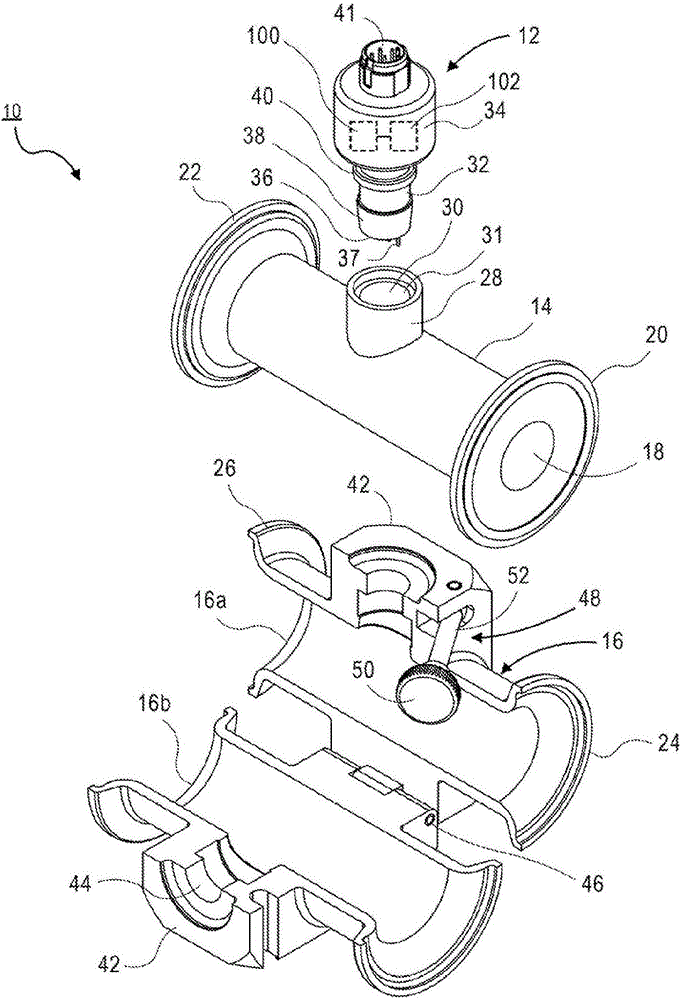

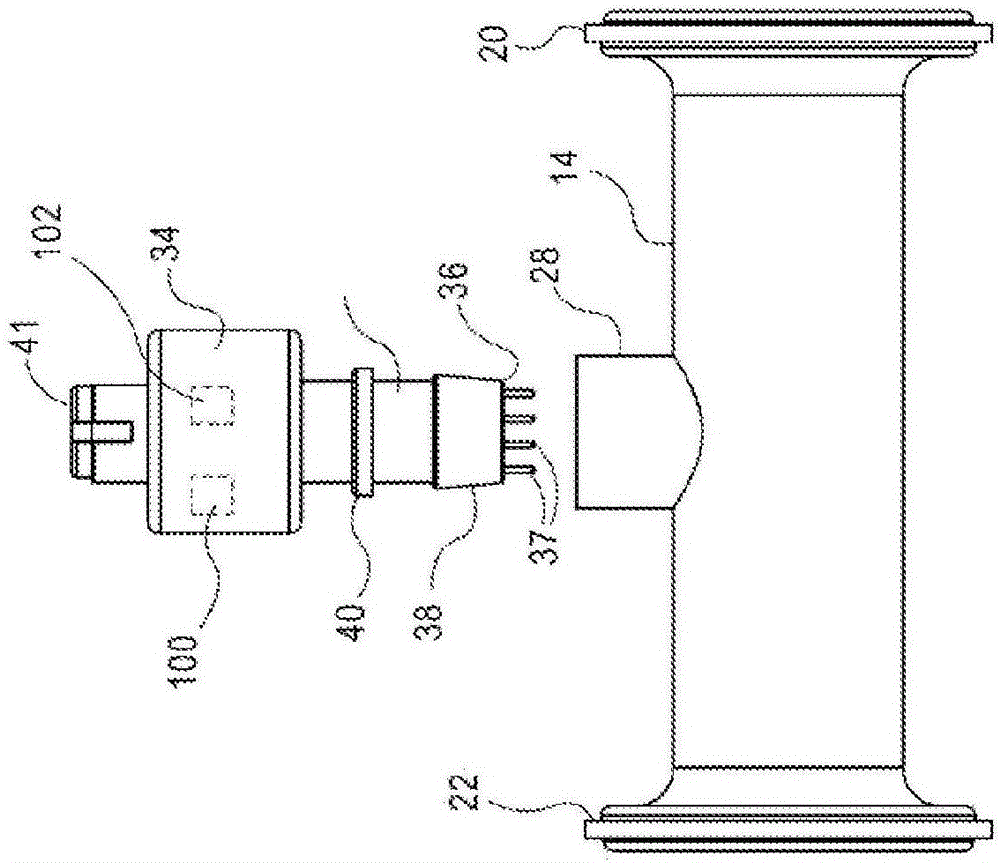

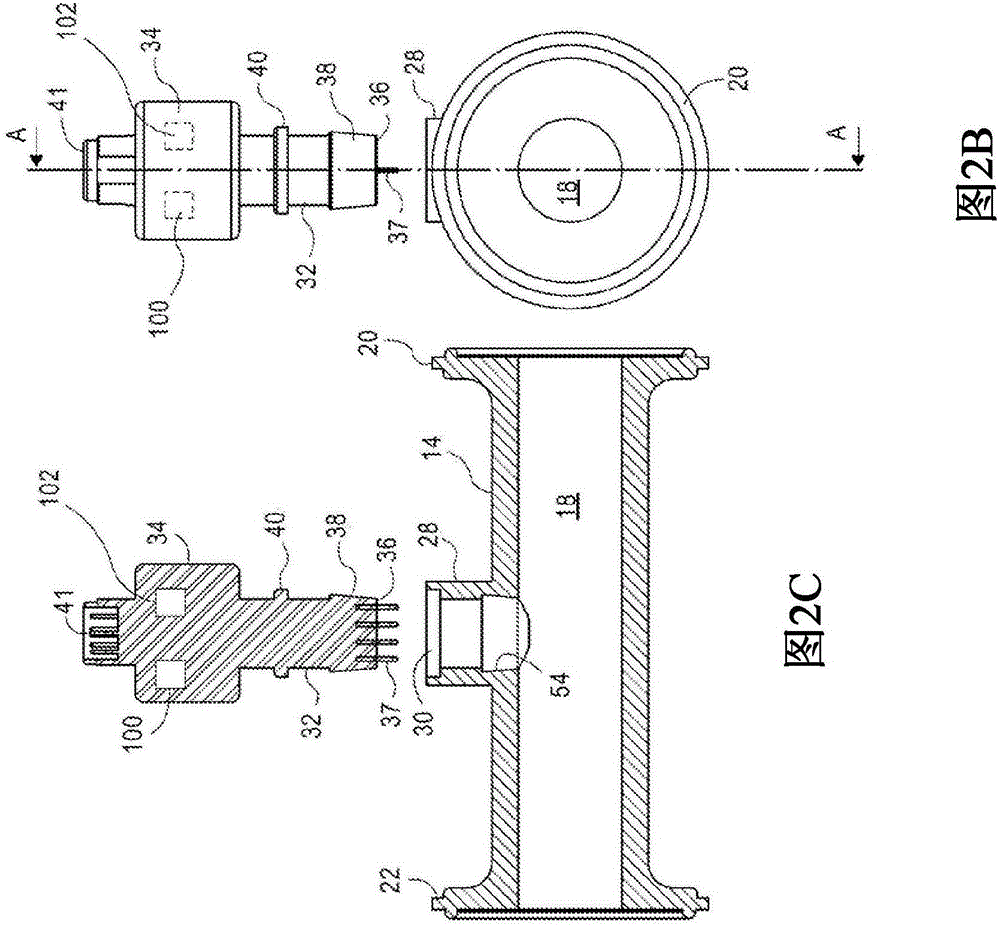

[0039] figure 1 One embodiment of a fluid monitoring assembly 10 is shown, according to one embodiment. The fluid monitoring assembly 10 includes a sensor 12 that is removably insertable within a catheter 14 . The conduit 14 may be designed as a length of unreinforced tubing in which a lumen 18 is defined by the walls of the conduit 14 . Fluid monitoring assembly 10 further includes a two-part housing 16 for enclosing conduit 14 and enclosing at least a portion of sensor 12 when sensor 12 is installed therein. The two-part housing 16 acts as a sleeve surrounding the conduit 14 and the portion of the sensor 12 contained therein. The two-part housing or sleeve 16 defines an exoskeleton-type structure that surrounds the unreinforced polymeric catheter 14 and prevents the unreinforced polymeric catheter 14 from failing under high fluid pressure (e.g., bursting or arterial formation in the catheter). tumor-type bumps). Fluid monitoring assembly 10 can handle very high fluid pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com