Stator of an electric machine and production thereof

A technology for stators and rotating electrical machines, applied in the manufacture of motor generators, use/manufacture of slot locking devices, electromechanical devices, etc., can solve problems such as laborious, manual insulation, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

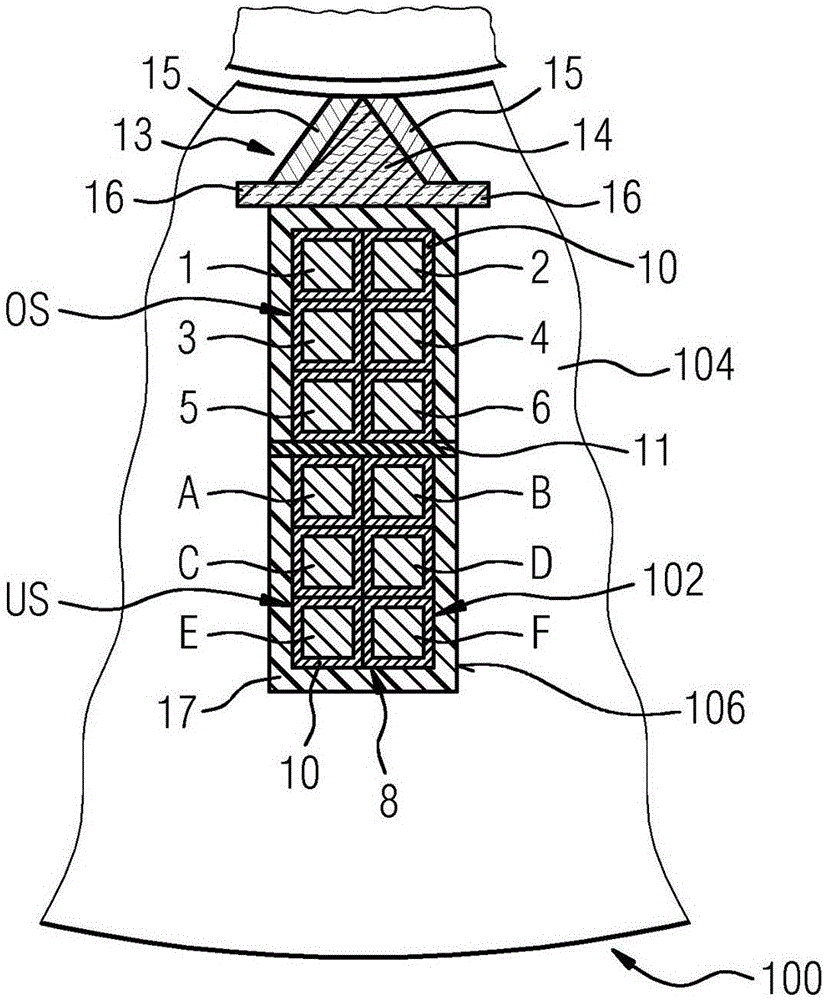

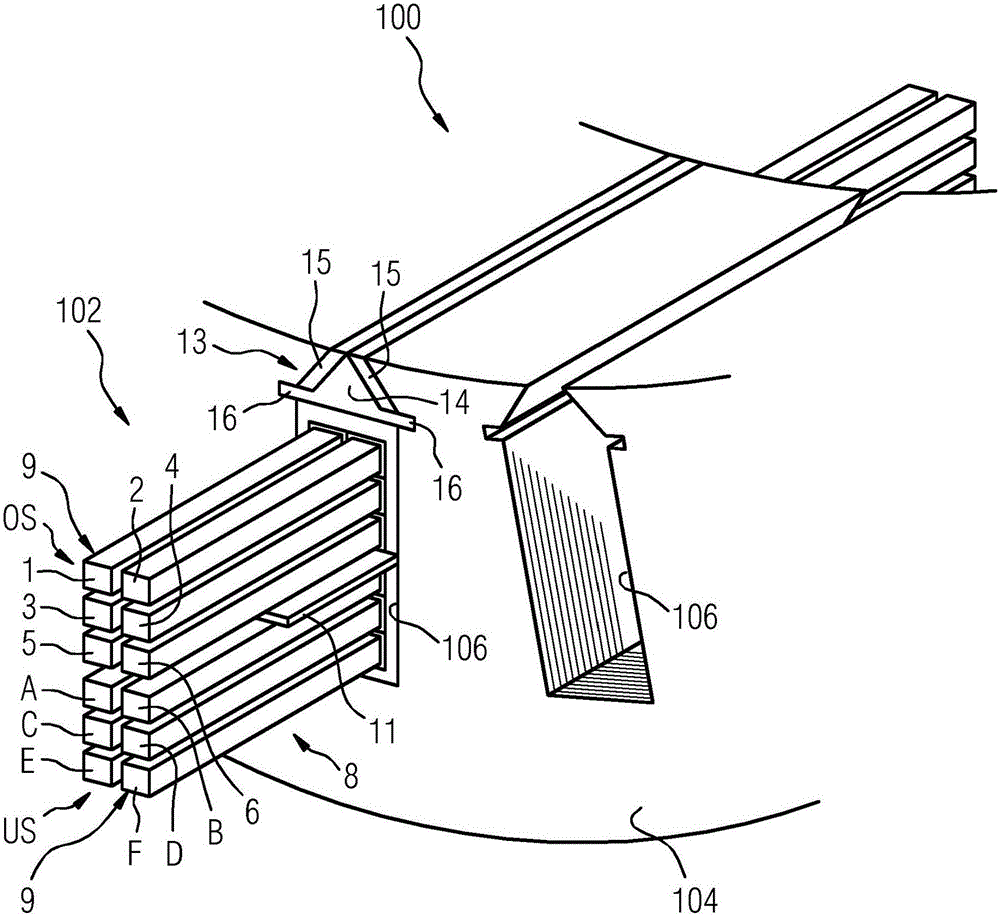

[0057] Mutually equivalent parts are provided with the same reference symbols in all figures.

[0058] Figures 1 to 6 A first exemplary embodiment of a stator 100 of a rotating electrical machine and a method for the automated production of a winding 102 of the stator 100 are shown. The stator 100 has a lamination stack 104 with a plurality of grooves 106 opening towards the air gap between the rotor of the electric machine and the stator 100 . The winding 102 consists of coils, the turns of which each run through the grooves 106 of the laminated core 104 .

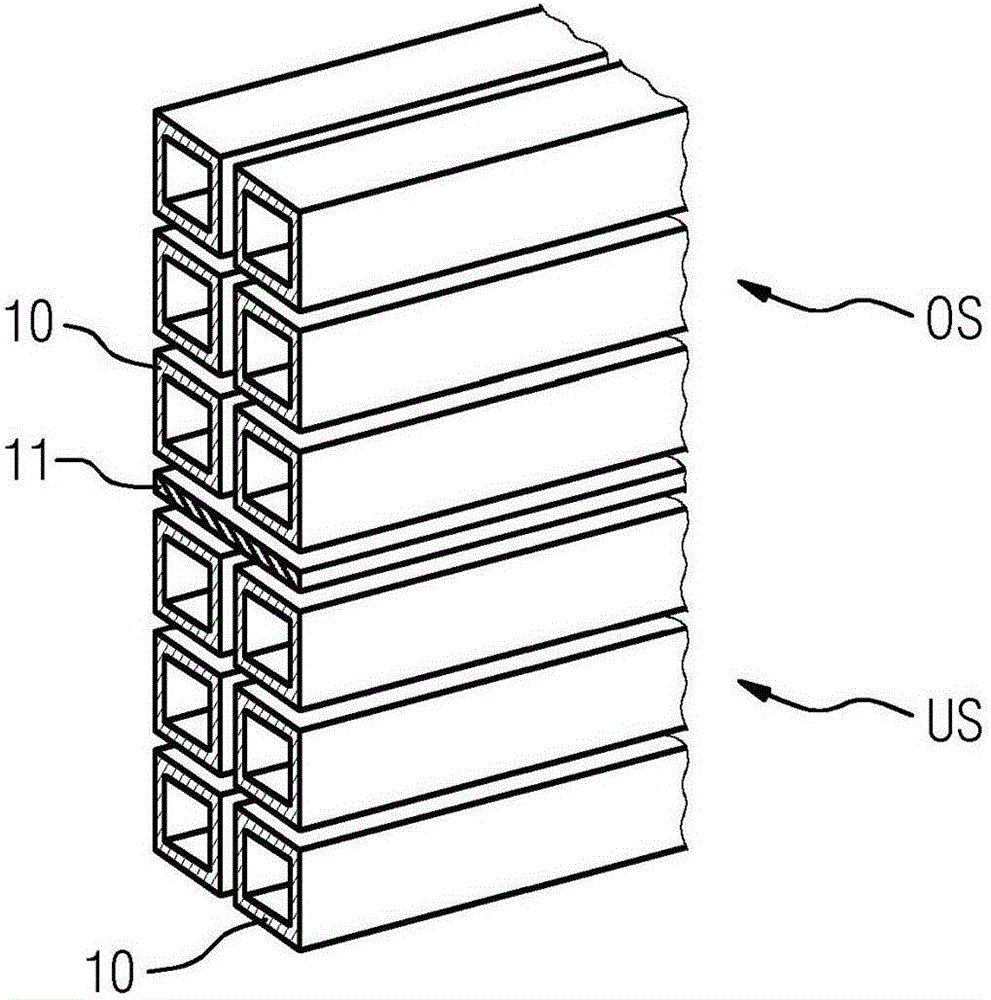

[0059] To manufacture the winding 102, in a variant of this embodiment first a plurality of figure 1 The straight, pipe-shaped insulating hollow body 10 shown in , is made of an electrically insulating insulating material, preferably a ceramic material. Each insulating hollow body 10 has at least the length of the groove 106 and has a cross-section with a triangular outer profile. The insulating hollow bodies 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com