Slicer retraction mechanism

A technology of retracting mechanism and slicer, which is applied in the direction of metal processing, etc., can solve the problems of easily reducing the service life of the blade, destroying the sample, and prone to sticking the knife, so as to protect the sample and the blade and prevent the sticking of the knife.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

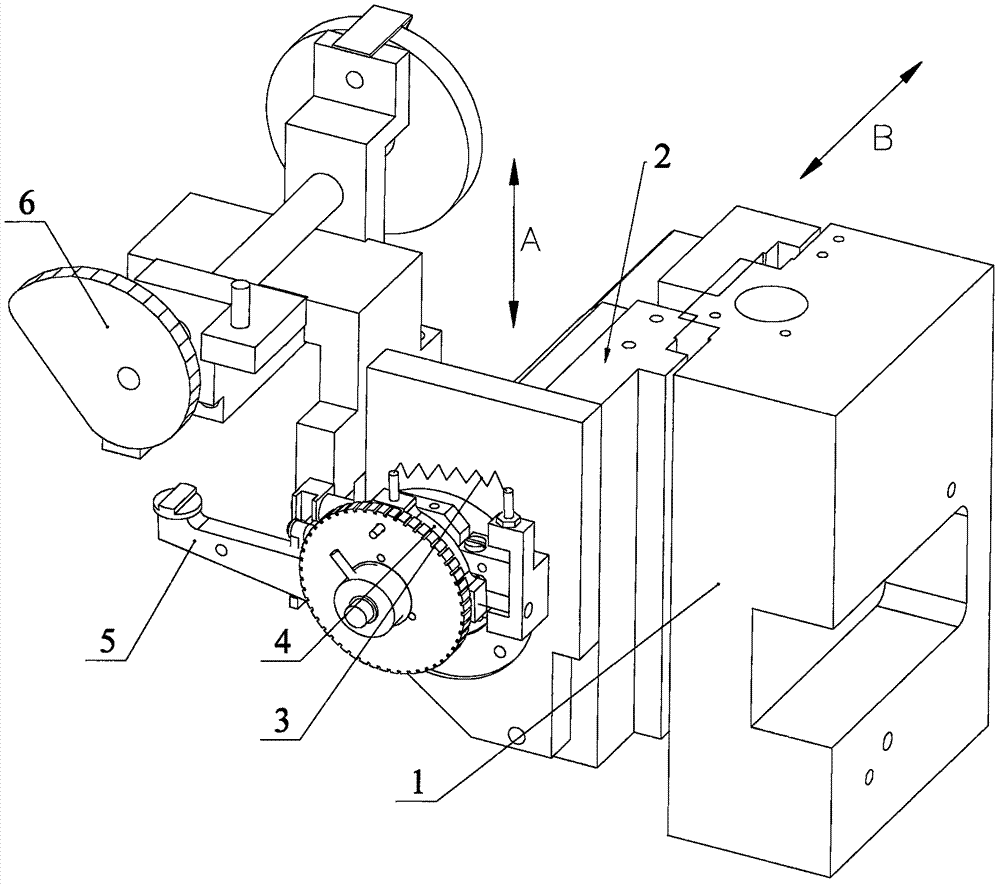

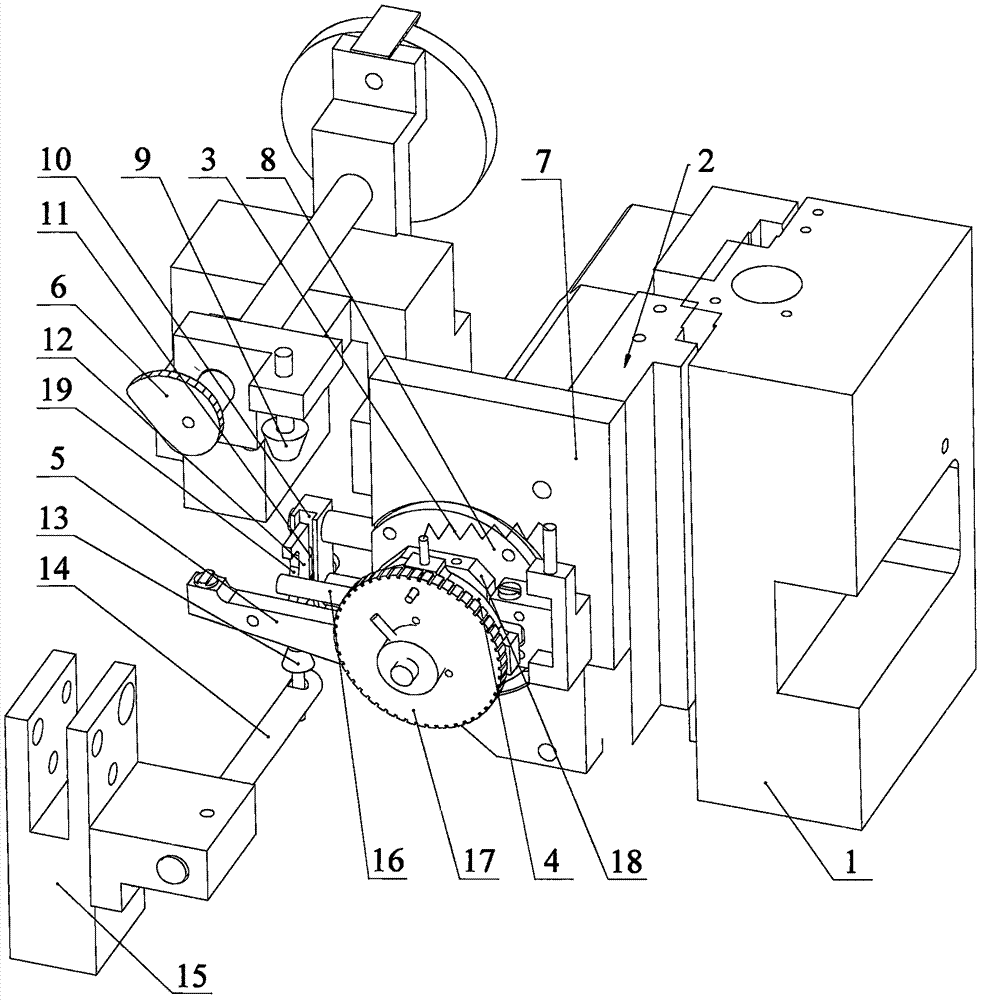

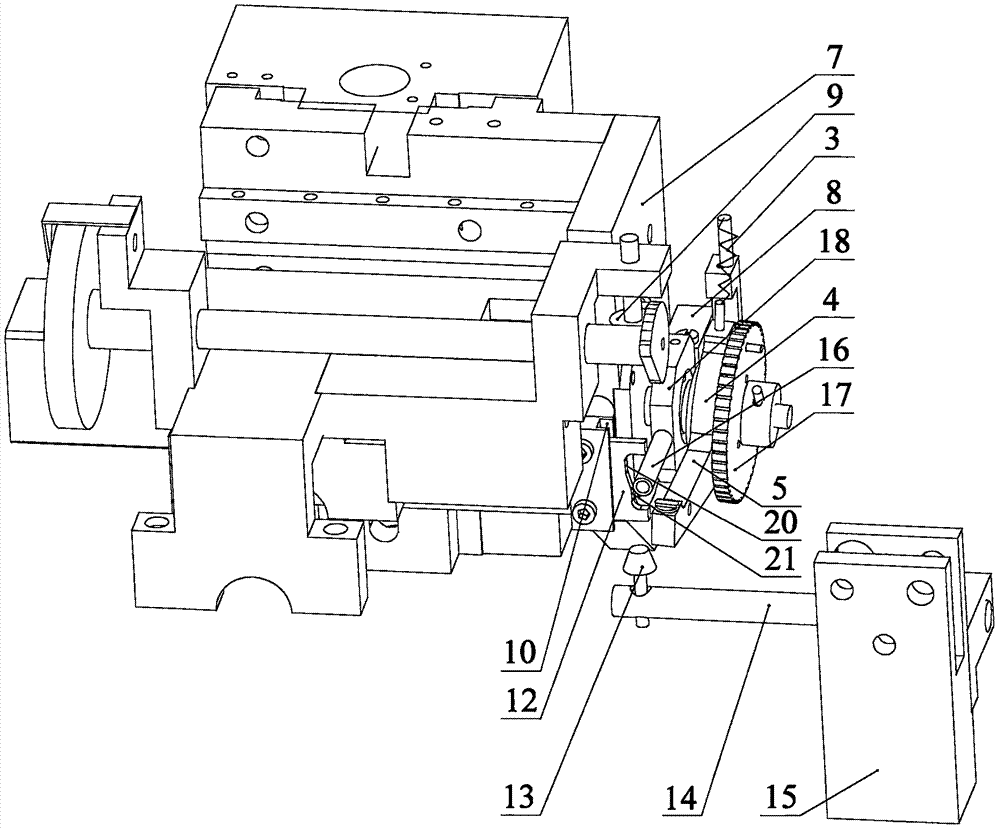

[0033] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0034] Such as figure 2 , 3 As shown in and 4, a slicer with a retraction mechanism, the slicer includes the structure mentioned in the background technology, that is, it includes a machine base 1, a moving seat 2, a return spring 3, a one-way bearing 4, a raised portion 5 and a For the eccentric disc 6, etc., wherein the moving base 2 is slidably arranged on the machine base 1, and the moving base 2 is provided with a sample delivery mechanism, the sample delivery mechanism includes a one-way bearing 4, and the inner ring of the one-way bearing 4 is connected with a screw rod 23, The moving seat 2 comprises a mounting plate 7, on which a through hole is provided for the threaded mandrel to pass, and the threaded mandrel has a limit ring 26, and the one-way bearing 4 and the limit ring 26 are located on both sides of the through hole respectively, and the retraction me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com