A preparation method of curved glulam components with shape springback compensation

A rebound compensation, glulam technology, applied in chemical instruments and methods, bonding of wooden veneers, other plywood/plywood appliances, etc., can solve problems such as inability to meet subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

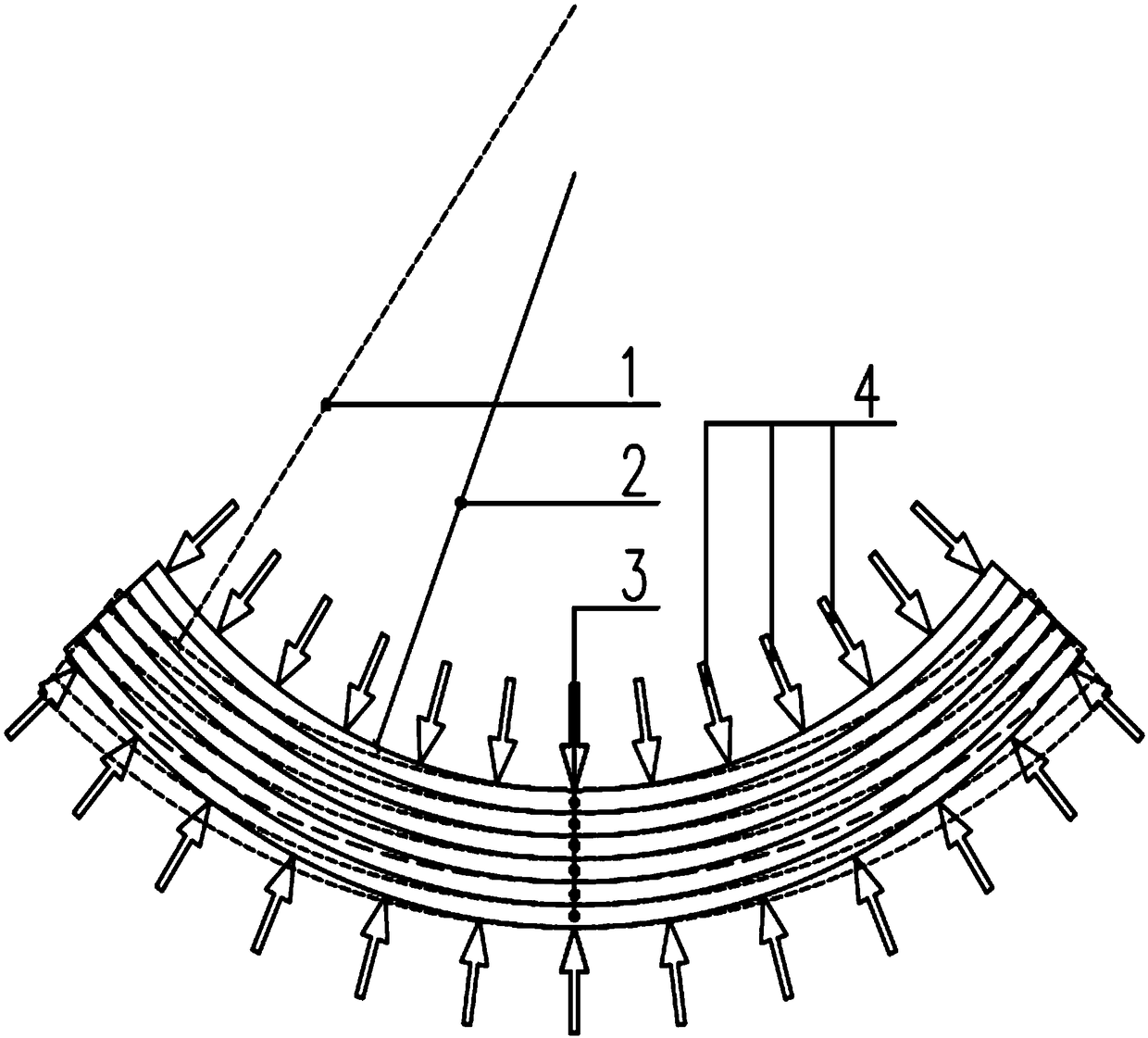

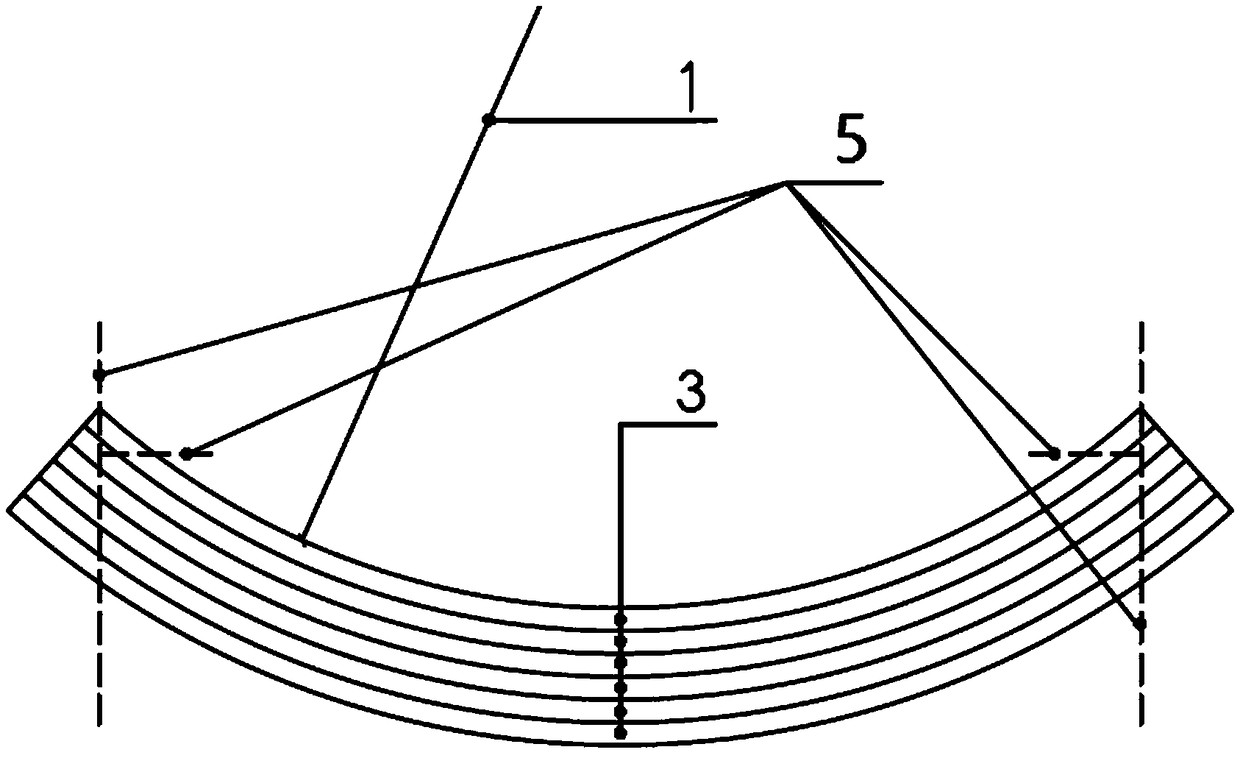

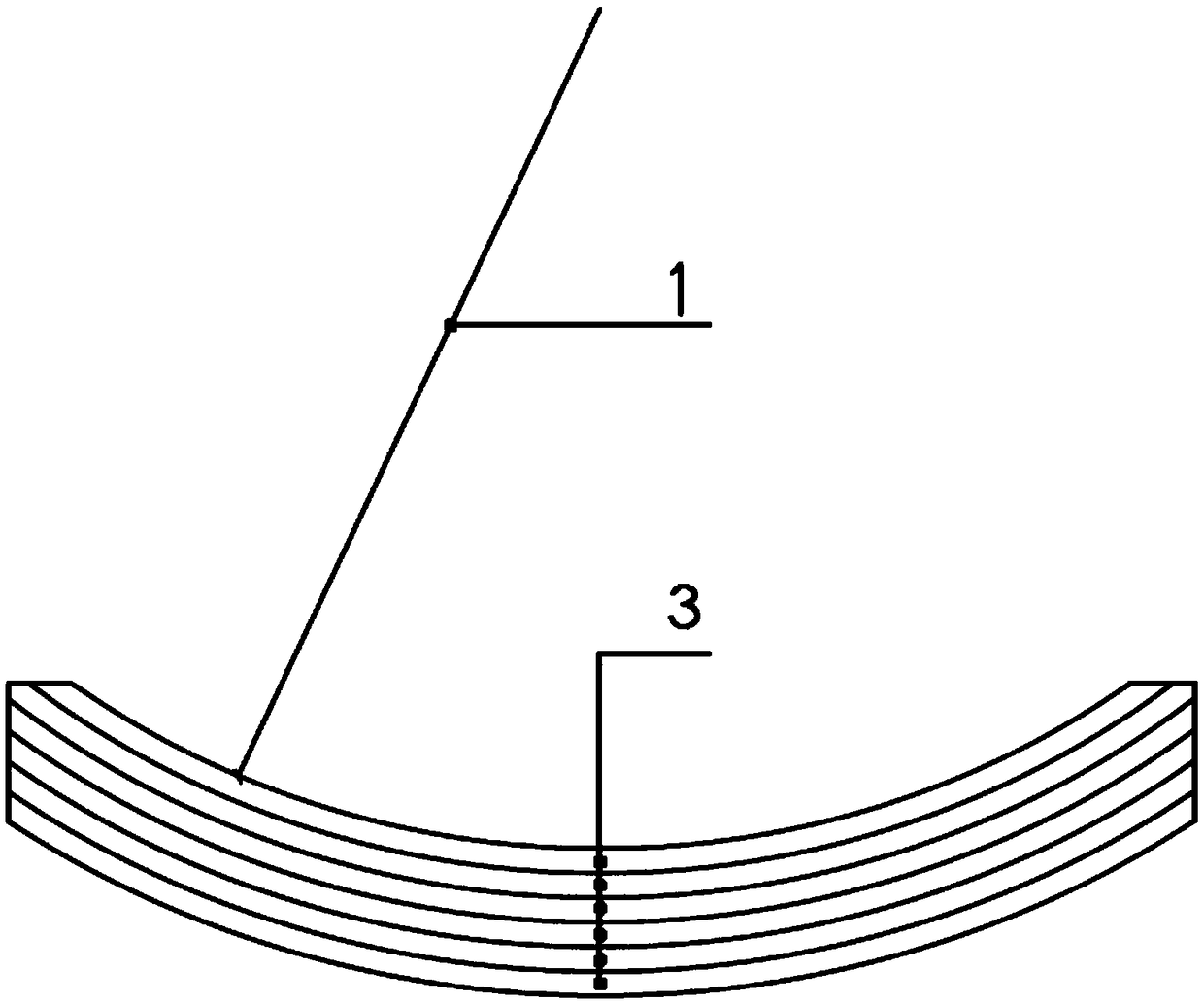

[0034] A method for preparing curved glulam components with shape springback compensation, including wood plywood gluing, profiling, pressurization and pressure relief curing, and these processes are all carried out under the environmental conditions of a temperature of 15°C and a relative humidity of 50%. Next complete.

[0035] The design radius of curvature of the European Scots pine arc-shaped glulam member is 111680mm, the chord length is 6600mm, and the section height is 450mm. The number of wooden laminates is 12, and the thickness of each layer is 37.5mm. The moisture content of the wood is 6%, which is compensated by springback deformation. According to the method, the radius of curvature for the preparation of curved glulam members is determined as:

[0036] The radius of curvature for the preparation of curved glulam components = the design radius of curvature of curved glulam components × (1-1 / number of wooden laminates) = 111680mm × (1-1 / 12) = 102373mm

[0037] A...

Embodiment 2

[0045] A method for preparing curved glulam components with shape springback compensation. The steps are the same as those in Example 1, including wood laminate gluing, profiling, pressurization and pressure relief maintenance. These processes are all carried out at a temperature of 18°C and a relative humidity of 70% complete under ambient conditions.

[0046] The design radius of curvature of Douglas-fir arc-shaped glulam members is 4800mm, the chord length is 5500mm, and the section height is 260mm. The number of wooden laminates is 7 layers, and the thickness of each layer is 37.1mm. The compensation method determines the curvature radius of the curved glulam member as:

[0047] The radius of curvature for the preparation of curved glulam components = the design radius of curvature of curved glulam components × (1-1 / number of wooden laminates) = 4800mm × (1-1 / 7) = 4114mm

[0048] The glue coating of the wooden laminate is 280g / m2 on one side 2 , the glue pressing time ...

Embodiment 3

[0053] A method for preparing curved glulam components with shape springback compensation, the steps are the same as those in Example 1, including wood plywood gluing, profiling, pressurization and pressure relief curing, these processes are all carried out at a temperature of 20°C and a relative humidity of 85% complete under ambient conditions.

[0054] The design radius of curvature of the southern pine arc-shaped glulam member is 5000mm, the chord length is 5800mm, and the section height is 375mm. The number of wooden laminates is 10, and the thickness of each layer is 37.5mm. The compensation method determines the curvature radius of the curved glulam member as:

[0055] Design radius of curvature of curved glulam components×(1-1 / number of wooden laminates)+[design radius of curvature of curved glulam components-design radius of curvature of curved glulam components×(1-1 / number of wooden laminates)] ×0.15=5000×(1-1 / 10)+[5000-5000×(1-1 / 10)]×0.15=4500+500×0.15=4575mm

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com