A giant all-steel engineering radial tire nozzle type hot water circulation vulcanization equipment and vulcanization process

A radial tire and hot water circulation technology, applied in the rubber field, can solve the problems of uneven heating of tire vulcanization, inconsistent vulcanization degree, uneven tire vulcanization, etc., and achieve the effect of reducing quality defects, uniform water temperature, and uniform tire vulcanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

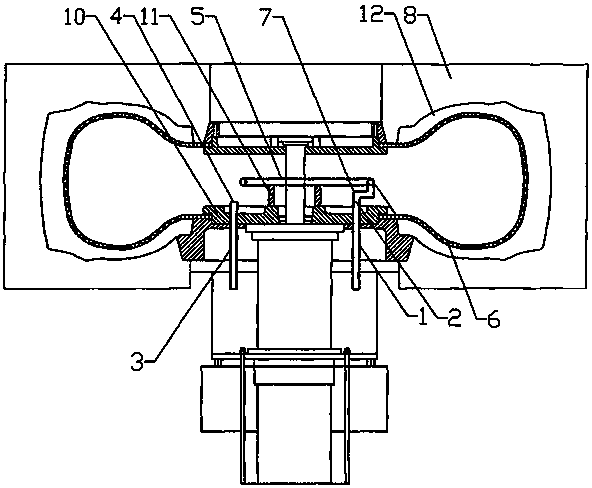

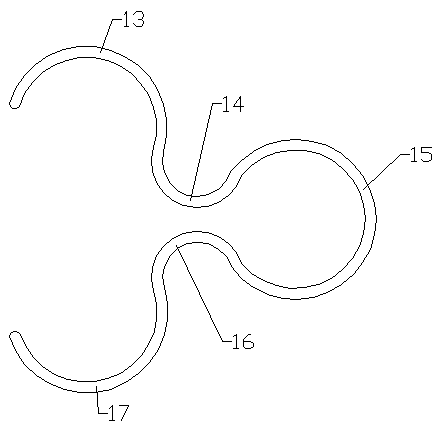

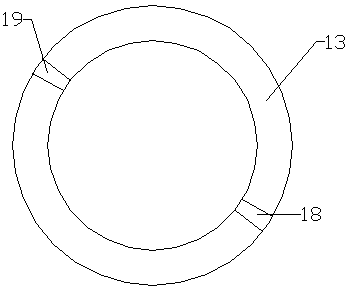

[0029] Examples, as attached figure 1 , attached figure 2 And attached image 3 As shown, a giant all-steel engineering radial tire nozzle type hot water circulation vulcanization equipment includes a vulcanization mold 8 and a water inlet pipeline 1 and a return water pipeline 3 arranged on the vulcanization mold 8, and a tire 12 is also arranged on the vulcanization mold 8 , the tire 12 is provided with a capsule 6, the water inlet pipeline 1 has a water inlet 2, the water return pipeline 3 has a water return outlet 4, the water inlet pipeline 1 and the water return pipeline 3 are connected with the capsule 6 respectively, and the capsule 6 is provided with a water inlet pipe The nozzle pipe 5 made of stainless steel connected to the road 1, the inner diameter of the nozzle pipe 5 is the same as the inner diameter of the water inlet pipe 1, the vulcanization mold 8 is provided with a lower chuck 10, and the nozzle pipe 5 is supported above the lower chuck 10 by a bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com