Feed carriage

A technology of feeding car and storage room, applied in the field of feeding car, can solve the problems of high labor cost, low production efficiency, confusion, etc., and achieve the effect of reducing labor intensity, facilitating free movement, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

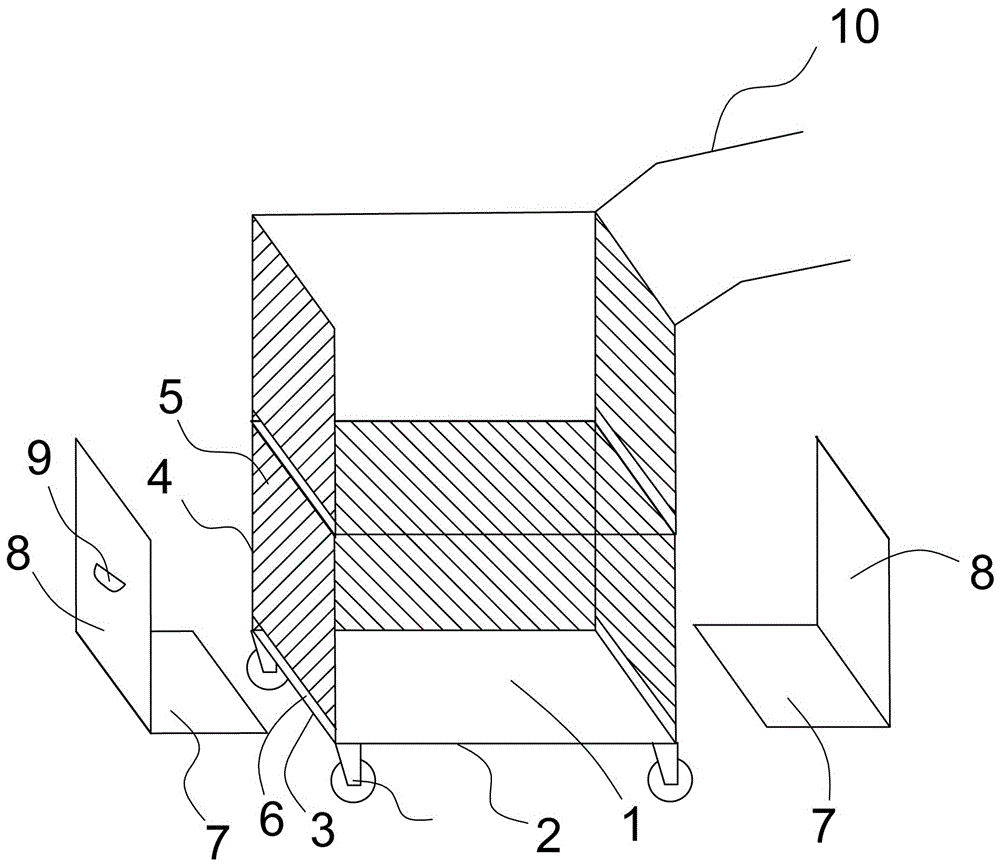

[0013] Such as figure 1 As shown, the present invention comprises at least one material storage chamber 1, and material storage chamber 1 comprises two longitudinal bars 2 arranged in parallel, and the transverse direction between two longitudinal bars 2 is provided with two cross bars 3 in parallel, and each longitudinal bar 2 Vertical rods 4 are welded at both ends of the vertical rod, the plane surrounded by the vertical rods 2 and the vertical rods 4 is provided with a baffle plate 5, the bottom of the baffle plate 5 is provided with a mounting hole 6, and the mounting hole 6 is movably connected with a load device. The arrangement of multiple storage chambers 1 can realize the simultaneous transmission of multiple pieces without collision between each piece, which improves the production efficiency. It has the characteristics of simple operation, stable operation, high work efficiency, high reuse rate and low cost.

[0014] The length of the mounting hole 6 is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com