A Converter Primary Flue Gas Adjustable Annular Seam Washing Dehydration Demist Integrated Tower

A technology of dehydration, defogging, and annular seam washing, which is applied in the direction of manufacturing converters, improving process efficiency, and improving energy efficiency. It can solve problems such as difficulty in improving dust removal efficiency, high free water content in flue gas, and huge water treatment equipment. Achieve the effects of improving gas quality, significant environmental benefits, reducing circulating water consumption and water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

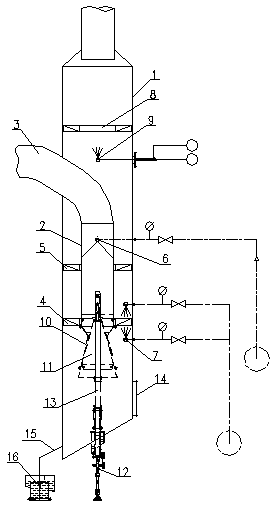

[0020] A converter integrated flue gas adjustable annular seam washing dehydration and defogging integrated tower, including a vertical tower body 1, the lower part of the tower body 1 is provided with an adjustable annular seam heavy hammer scrubber, the adjustable annular seam A smoke guide pipe 2 is installed on the upper end of the seam weight scrubber, and the smoke inlet end of the smoke guide pipe 2 is connected with the smoke outlet end of the smoke pipe 3, and the shell of the ring seam weight scrubber can be adjusted And the outer wall of the flue gas guide pipe 2 and the annular space surrounded by the tower body 1 are provided with several layers of outward-facing dust removal and dehydration swirl plates 4 located at the bottom of the flue gas diversion pipe 2. Above the flow plate 4, there are several layers of outward-facing dehydration and defogging swirl plates I5 located in the middle of the flue gas guiding pipe 2. The upper end of the flue gas guiding pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com