A thick-gauge x80 pipe fitting steel pipe with excellent low-temperature toughness and preparation method thereof

A low-temperature toughness and thick-gauge technology, which is applied in the field of thick-gauge X80 pipe fitting steel pipes and its preparation, can solve the problems that the influence of low-temperature toughness of pipe fitting steel is not considered, and it is difficult to ensure the low-temperature toughness of pipe fitting steel plates stably, so as to solve the process window Narrow, excellent low temperature toughness, the effect of excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

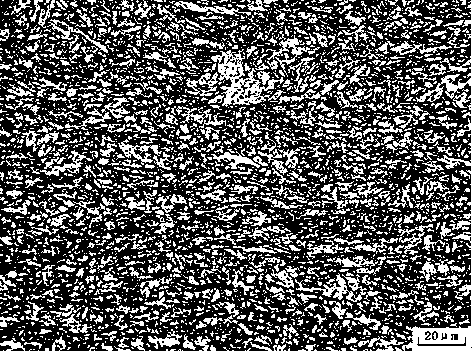

Image

Examples

Embodiment 1

[0035] The thick-gauge X80 fitting steel pipe with excellent low-temperature toughness is prepared from the following components in mass percentage: C: 0.04%, Si: 0.20%, Mn: 1.70%, P=0.005%, S=0.001%, Nb: 0.035%, Mo: 0.20%, Cu: 0.10%, Cr: 0.15%, Ni: 0.15%, Ti: 0.03%, Al: 0.01%, N=0.002%, Ti / Al=3, Al / N=5, V:0.02%, Pcm=0.16%, Ceq=0.41%.

[0036] The balance is Fe and unavoidable impurities.

[0037] The preparation method is as follows:

[0038] 1) Steel plate milling and forming process: Both sides of the steel plate are milled at 20mm. The steel plate adopts the JCOE forming process. First, the steel plate is pressed into a "J" shape, and then the other half of the steel plate is pressed into a "C" shape, and finally the opening is formed. "O" shape, a total of 21 stamping passes, including 4 passes for pressing "J" shape, 13 passes for "C" shape, 4 passes for pressing "O" shape, after each pass is pressed The next pass of deformation is carried out with an interval of 5 se...

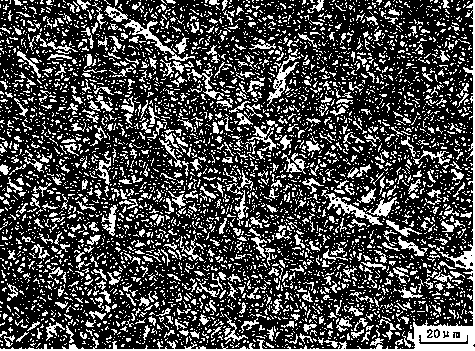

Embodiment 2

[0046] The thick-gauge X80 fitting steel pipe with excellent low-temperature toughness is prepared from the following components by mass percentage: C: 0.07%, Si: 0.30%, Mn: 1.90%, P=0.010%, S=0.005%, Nb: 0.070%, Mo: 0.25%, Cu: 20%, Cr: 0.25%, Ni: 0.30%, Ti: 0.04%, Al: 0.02%, N=0.005%, Ti / Al=3, Al / N=2, V:0.04%, Pcm=0.22%, Ceq=0.53%.

[0047] The preparation method is as follows:

[0048] 1) Steel plate milling and forming process: Both sides of the steel plate are milled at 20mm. The steel plate adopts the JCOE forming process. First, the steel plate is pressed into a "J" shape, and then the other half of the steel plate is pressed into a "C" shape, and finally the opening is formed. "O" shape, a total of 23 stamping passes, including 5 passes for pressing "J" shape, 15 passes for "C" shape, 3 passes for pressing "O" shape, after each pass is pressed Intermittent 6 seconds to carry out the next pass of deformation, the reduction of each pass is carried out in an incremental ...

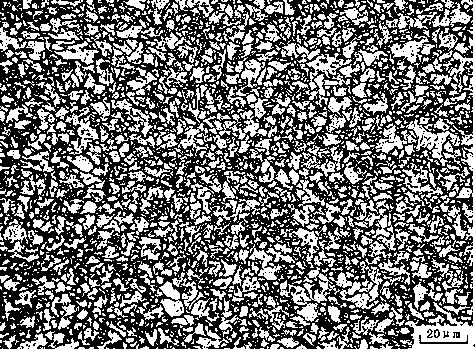

Embodiment 3

[0056] The thick-gauge X80 fitting steel pipe with excellent low-temperature toughness is prepared from the following components by mass percentage: C: 0.05%, Si: 0.25%, Mn: 1.80%, P=0.008%, S=0.002%, Nb: 0.050%, Mo: 0.20%, Cu: 0.15%, Cr: 0.20%, Ni: 0.20%, Ti: 0.031%, Al: 0.015%, N=0.004%, Ti / Al=2, Al / N=3.75, V:0.03%, Pcm=0.19%, Ceq=0.46%.

[0057] The preparation method is as follows:

[0058]1) Steel plate milling and forming process: Both sides of the steel plate are milled at 20mm. The steel plate adopts the JCOE forming process. First, the steel plate is pressed into a "J" shape, and then the other half of the steel plate is pressed into a "C" shape, and finally the opening is formed. "O" shape, a total of 23 stamping passes, including 4 passes for pressing "J" shape, 14 passes for "C" shape, 5 passes for pressing "O" shape, after each pass is pressed Intermittently 5.5 seconds to carry out the next pass of deformation, the reduction of each pass is carried out in an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com