Sewing machine bobbin thread residue detection device

A detection device and sewing machine technology, applied in sewing machine control devices, bobbin winding in sewing machines, sewing machine components, etc., can solve the problems of defective high-end fabrics, failure to stop and alarm in time, etc., to ensure sewing quality and ensure sewing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: The winding counting device of this embodiment is a switch counting device.

[0040] The switch counting device comprises a pressure sensor 3 or a switch arranged on the wire pressing control board 2 of the wire winder or on the connecting rod 26 of the wire winder.

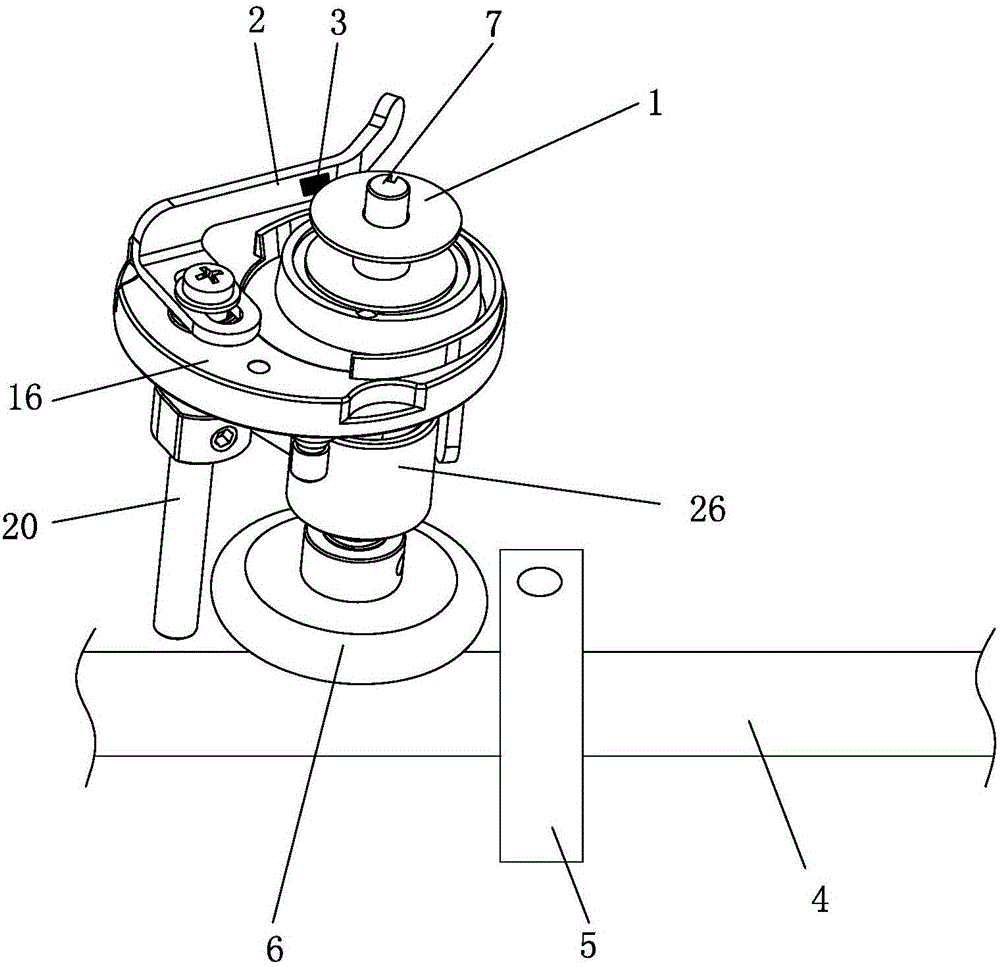

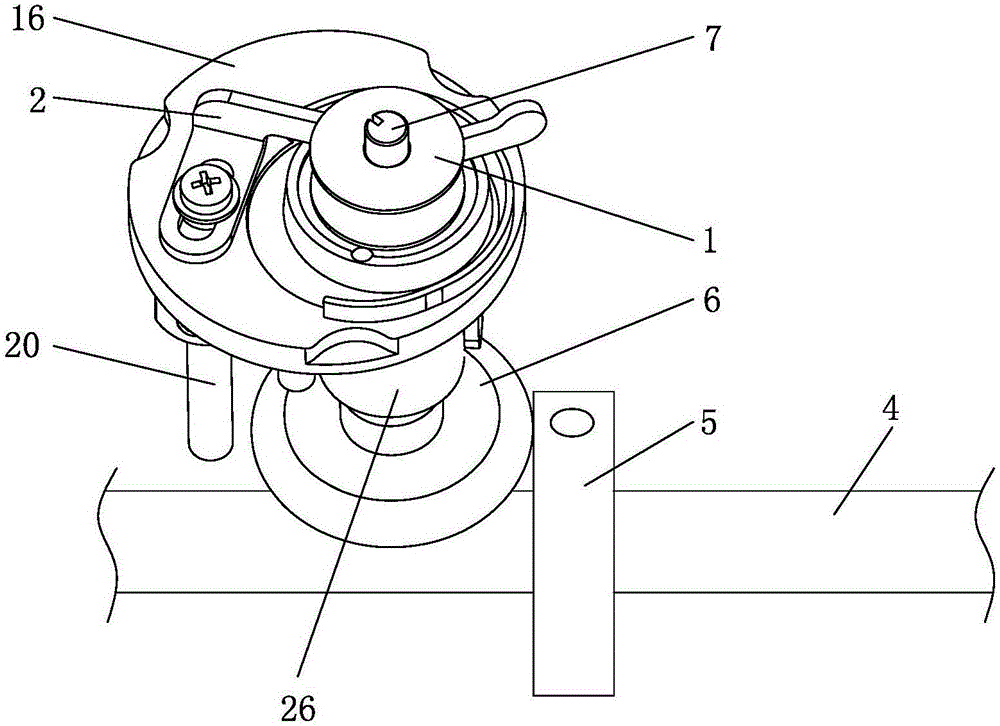

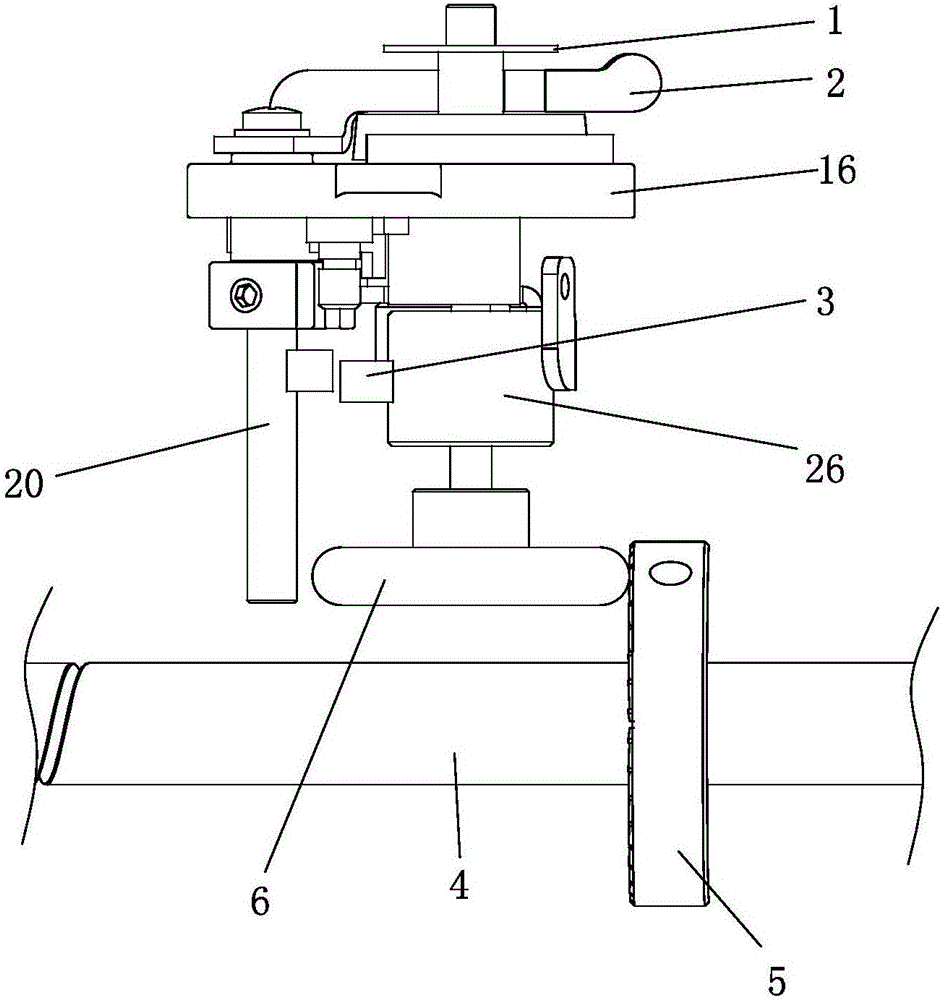

[0041] Such as figure 1 As shown, it is the state diagram of the lockstitch sewing machine when the winder is not working. Bobbin 1 is sleeved on the bobbin shaft 7 of bobbin winder. At this moment, the winding driving wheel 5 is not in contact with the winding wheel 6, and the thread pressing control plate 2 is not in contact with the bobbin 1. At this time, the pressure sensor 3 is not connected or the switch is not connected. Such as figure 2As shown, it is the state diagram of the winder when it is working. At this moment, the winding driving wheel 5 contacts the winding wheel 6, the pressure sensor 3 contacts the bobbin 1, the pressure sensor 3 on the pressure control plate 2 is to...

Embodiment 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the winding counting device adopts a Hall induction counting device.

[0052] The Hall induction counting device includes a side surface of the winding liner 14 (such as image 3 shown) or the upper surface (such as Figure 4 Shown) or the magnet one 15 of lower surface and the hall sensor one 17 that is arranged on the winding device main seat 16. Wherein, the Hall sensor one 17 is arranged on the main seat 16 of the winding device through the sensor bracket 18 .

[0053] When the winder on the top of the sewing machine head is working, the working state is as follows: image 3 , 4 As shown, the bobbin 1 is placed above the winding liner 14, and the thread pressing control panel 2 is pulled in the direction of the bobbin 1, and now the bobbin 1 starts to wind. When winding, the winding liner 14 is relatively fixed to the bobbin 1, that is, the number of turns of the winding liner 14 and t...

Embodiment 3

[0054] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the winding counting device adopts another Hall induction counting device.

[0055] Such as Figure 5 As shown, when the bobbin winder is winding, since the winding wheel 6 and the bobbin 1 are also relatively fixed, that is, the number of turns of the winding wheel 6 and the bobbin 1 is consistent. Therefore, present embodiment is provided with magnet 2 19 on the winding wheel 6, is provided with support 21 on the winding camshaft 20 of winding device, and one end of support 21 is sleeved on the winding camshaft 20 and is fixed by screw, and another One end is positioned above the reel 6 . Hall sensor 2 22 is arranged on the bracket 21 above the reel 6 . When winding, the winding wheel 6 rotates, and the magnet 2 19 approaches the Hall sensor 22 once every time, that is, every time the winding wheel 6 turns around, the Hall sensor 22 counts up by one until the winding is completed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com