V-shaped gap for decorating wall space

A wall decoration and shape technology, applied in the field of V-shaped joints, can solve the problems of rough surface of V-shaped grooves, affecting the appearance of walls, and non-uniform shapes of V-shaped cross-sections, so as to reduce overall costs, enhance safety, and V-shaped joints. The effect of shape seam specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

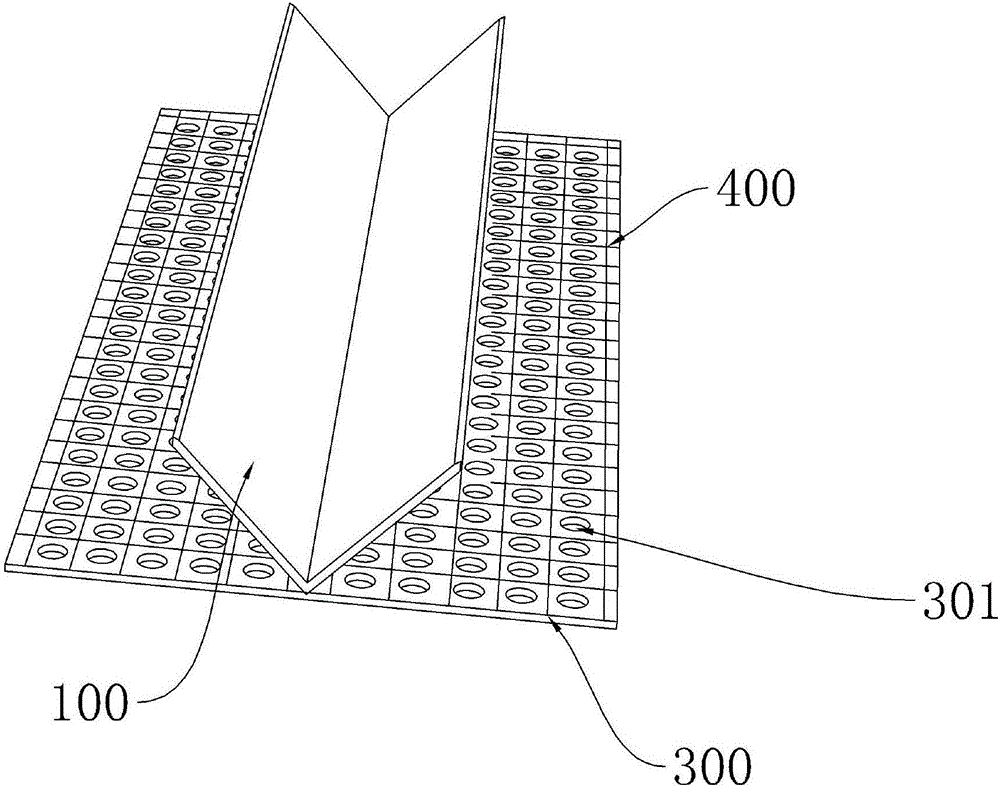

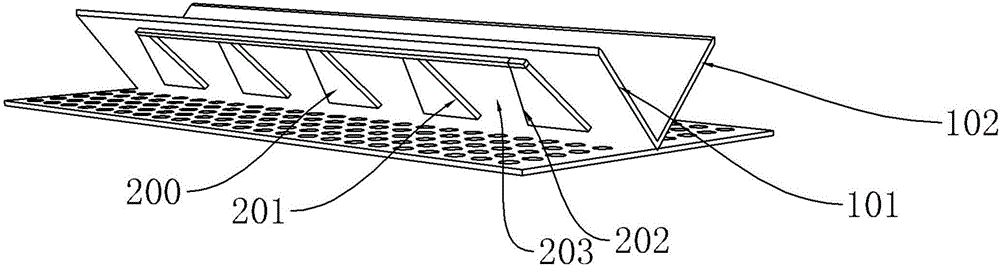

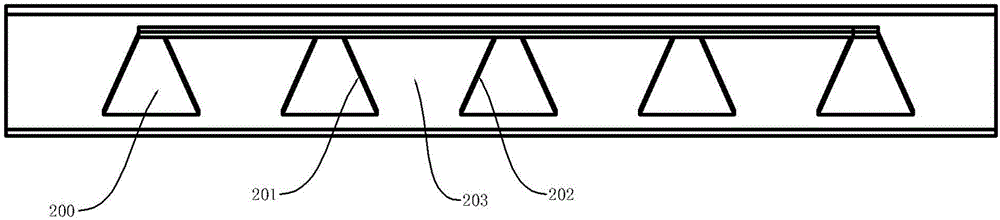

[0036] see Figure 1 to Figure 4 , a V-shaped seam for wall decoration, including a V-shaped body 100, the V-shaped body 100 is composed of a first slanted plate 101 and a second slanted plate 102, and the first slanted plate 101 and the second slanted plate 102 The plates 102 are respectively connected through their respective second connection ends and second secondary connection ends, and form a V-shaped groove with a V-shaped included angle a;

[0037] The V-shaped body 100 is made of hot-dip galvanized steel strip, and the value range of the V-shaped included angle a is 15°-175°. Of course, the V-shaped body 100 can also be made of PVC or aluminum alloy. At this time, the value of the V-shaped angle a should be 20°-160°. This is mainly due to the material characteristics of PVC or aluminum alloy. Too small or too large a V-shaped angle will affect the strength of the V-shaped body;

[0038] Further, in order to make the rigidity of the V-shaped body meet the requirement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com