Linear push bench slide mechanism

A sliding mechanism, straight line technology, applied in multi-purpose machinery, wood processing appliances, sawing components, etc., can solve the problems of poor straightness and poor wear resistance of linear push tables, achieve good straightness and improve sliding wear resistance. , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

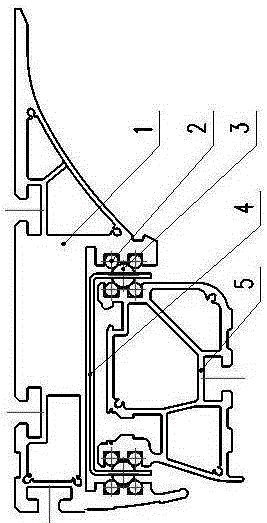

[0009] As shown in the figure, there are drooping convex edges on both sides of the elongated push platform table top 1, the upper part of the elongated base 5 is embedded in the convex edges on both sides of the table top 1, and the inner side of the lower convex edge of the table top 1 Two upper and lower steel round bars 2 are installed on the upper and lower sides of the base 5 respectively. The steel round bars 2 on the convex edge of the table top 1 and the steel round bars 2 on both sides of the base 5 form a square angle, and a plurality of steel balls are embedded in the middle. 3. The steel ball 3 is fixed between the table 1 and the base 5 by the frame-like cage 4 . When pushing the push table top 1, the rolling of the steel ball 3 cooperates with the steel round bar 2 to make the push table top 1 slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com