Lubricating grease injected adjustable sealing ring

A sealing ring and grease technology, which is applied to engine components, piston rings, mechanical equipment, etc., can solve the problems of inability to adjust the sealing performance of the sealing ring, the reduction of the volume efficiency of the hydraulic cylinder, and the inability of the hydraulic cylinder to work, so as to achieve the ability to adjust the sealing performance. , long service life, anti-twist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

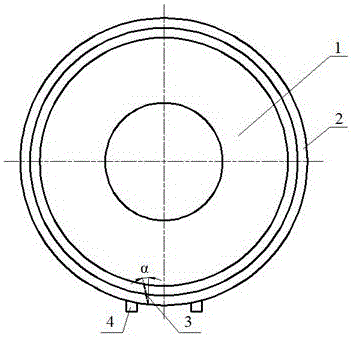

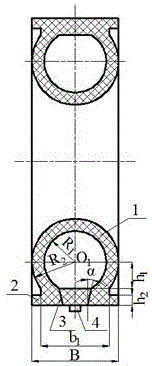

[0024] An adjustable seal ring filled with grease. Such as figure 1 and figure 2 As shown, the adjustable sealing ring is an integral body composed of a hollow O-ring 1 and an annular base 2 , and the outer wall of the hollow O-ring 1 is in close contact with the inner wall of the annular base 2 . The outer wall of the annular base 2 is provided with a grease injection hole 3 to the cavity of the hollow O-ring 1 , and the outer wall of the annular base 2 is provided with two positioning pins 4 .

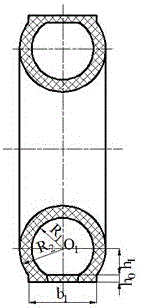

[0025] Such as image 3 As shown, the cross-sectional shape of the hollow O-ring 1 is composed of an approximate circular tube with the center line of the adjustable sealing ring as the axis of symmetry, and the approximate circular tube is composed of O 1 The approximate inner circle with the center as the center and the O 1 It is surrounded by an approximate outer circle with the same center. The approximate inner circle is given by R 1 It is formed by connecting the inner c...

Embodiment 2

[0031] An adjustable seal ring filled with grease. Except following technical parameter, all the other are with embodiment 1.

[0032] The inclination angle α=20°~25° of the expanding paraboloid;

[0033] The parabolic opening width b on the outer wall of the annular base 2 2 =0.35~0.4B, the length L of the projection of the parabola on the horizontal plane on the outer wall of the annular base 2 along the axis of symmetry=0.35~0.4B.

[0034] Compared with the prior art, this specific embodiment has the following advantages:

[0035](1) The outer ring surface of the annular base 2 in this specific embodiment has a grease injection through hole 3, and the grease injection through hole 3 is cut into a gradually expanding paraboloid along the parabola of the orifice and along the outside of the parabola, that is, gradually The expanded paraboloid is composed of a variable cross-section parabola, and the inclination angle of the variable cross-section is α=15~25°; the parabol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap