Refrigerating system and control method thereof

A refrigeration system and valve port technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of long defrosting time and low temperature of defrosting flow path, and achieve short defrosting time and high average heating capacity , Improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

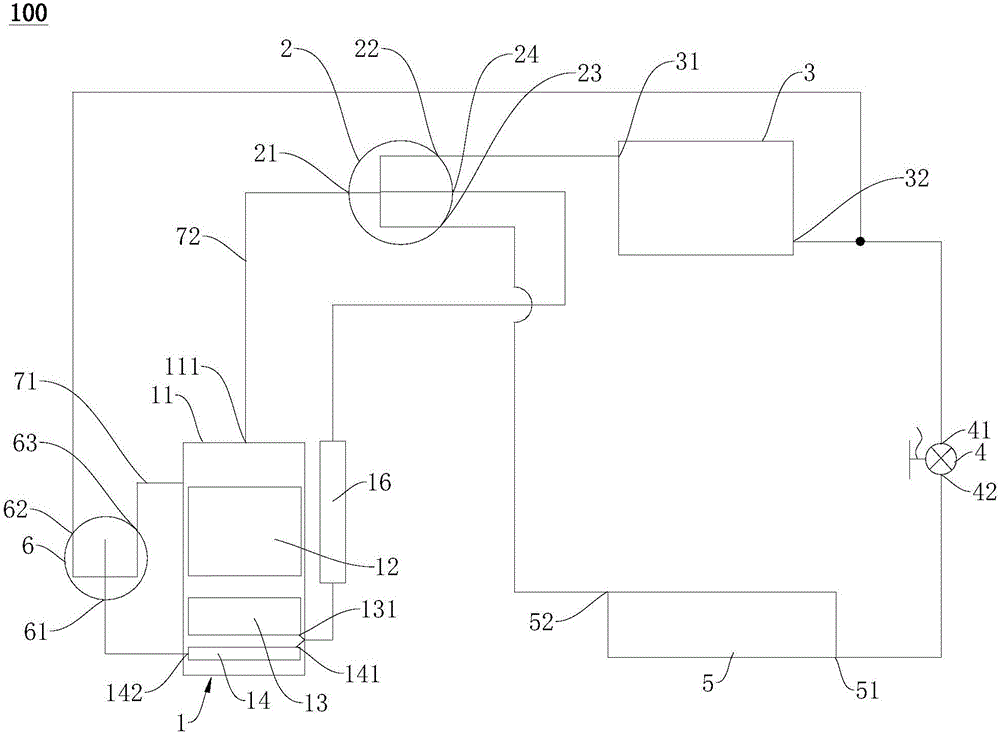

[0053] refer to figure 1 , in this embodiment, the refrigeration system 100 includes the compressor 1 , the four-way valve 2 , the outdoor heat exchanger 3 , the throttling device 4 and the indoor heat exchanger 5 . The refrigeration system 100 also includes a three-way valve 6, the three-way valve 6 has a fifth valve port 61, a sixth valve port 62 and a seventh valve port 63, the fifth valve port 61 is connected to the second exhaust port 142, the sixth valve port The port 62 is connected to the second outdoor heat exchange port 32 , and the seventh valve port 63 is connected to the inner cavity of the casing 11 . Thus, when the fifth valve port 61 communicates with the sixth valve port 62, the second exhaust port 142 communicates with the second outdoor heat exchange port 32 and is blocked from the main exhaust port 111; When the seven valve ports 63 are connected, the second exhaust port 142 is connected to the main exhaust port 111 and blocked from the second outdoor heat...

Embodiment 2

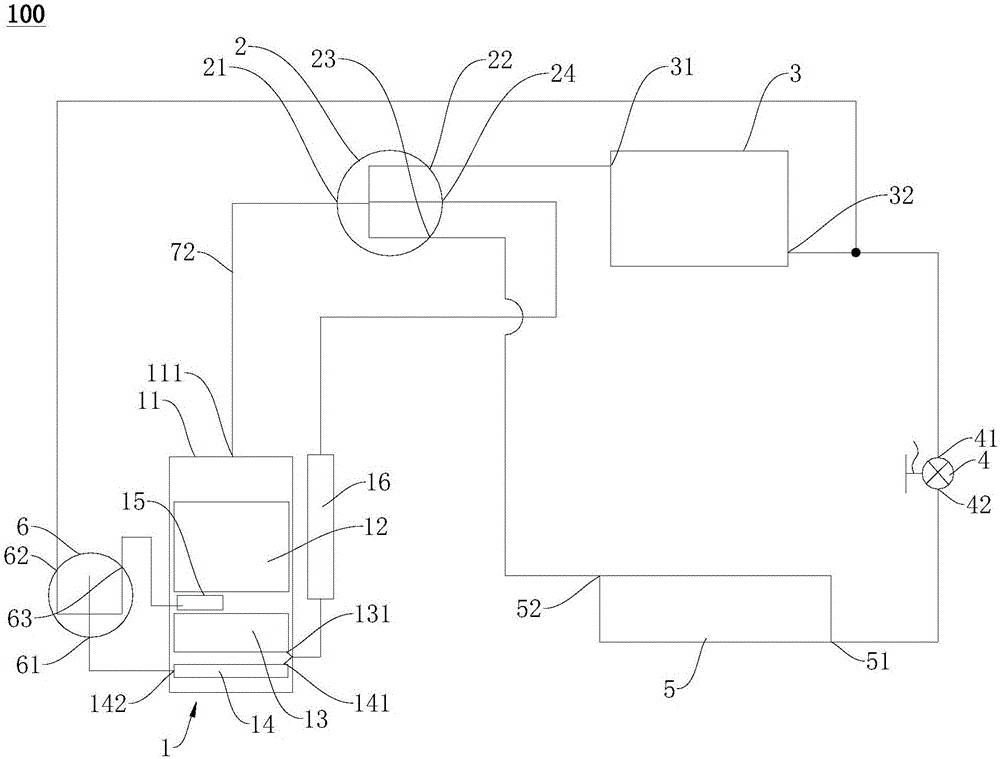

[0056] refer to figure 2, in this embodiment, the refrigeration system 100 includes the compressor 1 , the four-way valve 2 , the outdoor heat exchanger 3 , the throttling device 4 and the indoor heat exchanger 5 . The refrigeration system 100 also includes a three-way valve 6, the three-way valve 6 has a fifth valve port 61, a sixth valve port 62 and a seventh valve port 63, the fifth valve port 61 is connected to the second exhaust port 142, the sixth valve port The port 62 is connected to the second outdoor heat exchange port 32 , and the seventh valve port 63 is connected to the inner cavity of the casing 11 . Thus, when the fifth valve port 61 communicates with the sixth valve port 62, the second exhaust port 142 communicates with the second outdoor heat exchange port 32 and is blocked from the main exhaust port 111; When the seven valve ports 63 are connected, the second exhaust port 142 is connected to the main exhaust port 111 and blocked from the second outdoor heat...

Embodiment 3

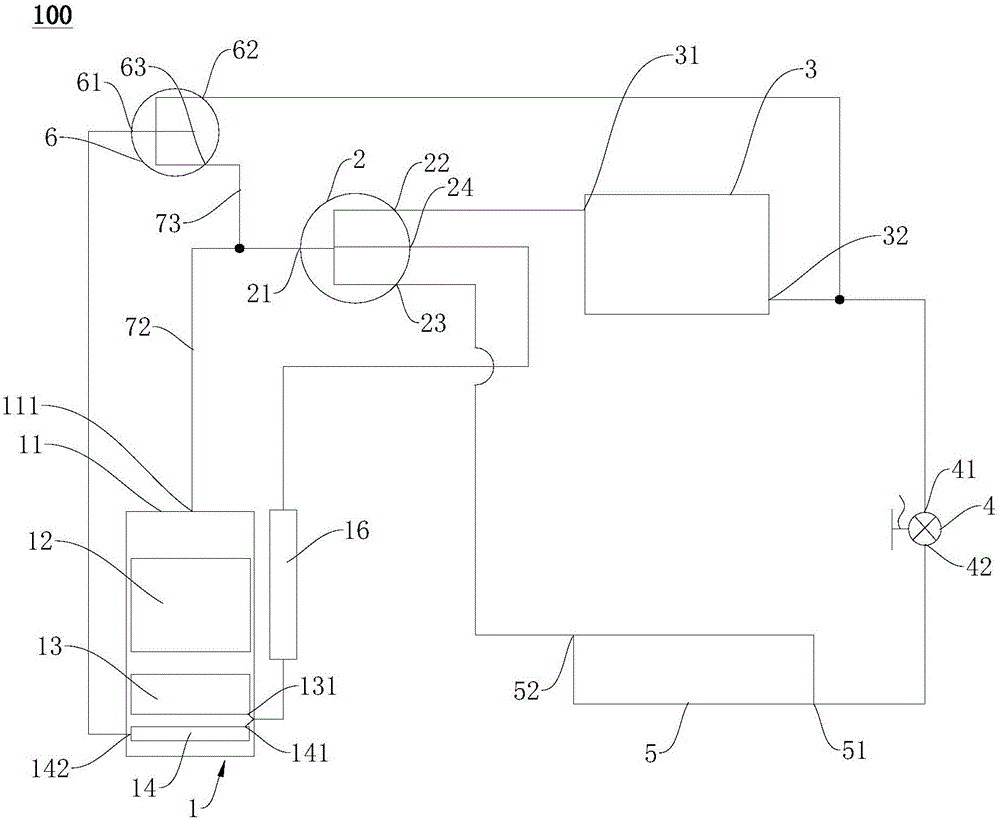

[0059] refer to image 3 , in this embodiment, the refrigeration system 100 includes the compressor 1 , the four-way valve 2 , the outdoor heat exchanger 3 , the throttling device 4 and the indoor heat exchanger 5 . The refrigeration system 100 also includes a three-way valve 6, the three-way valve 6 has a fifth valve port 61, a sixth valve port 62 and a seventh valve port 63, the fifth valve port 61 is connected to the second exhaust port 142, the sixth valve port The port 62 is connected to the second outdoor heat exchange port 32 , and the seventh valve port 63 is connected to the inner cavity of the housing 11 . Thus, when the fifth valve port 61 communicates with the sixth valve port 62, the second exhaust port 142 communicates with the second outdoor heat exchange port 32 and is blocked from the main exhaust port 111; When the seven valve ports 63 are connected, the second exhaust port 142 is connected to the main exhaust port 111 and blocked from the second outdoor hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com