Energy-saving operation method, evaluation method, device and system in the machining stage of CNC machine tools

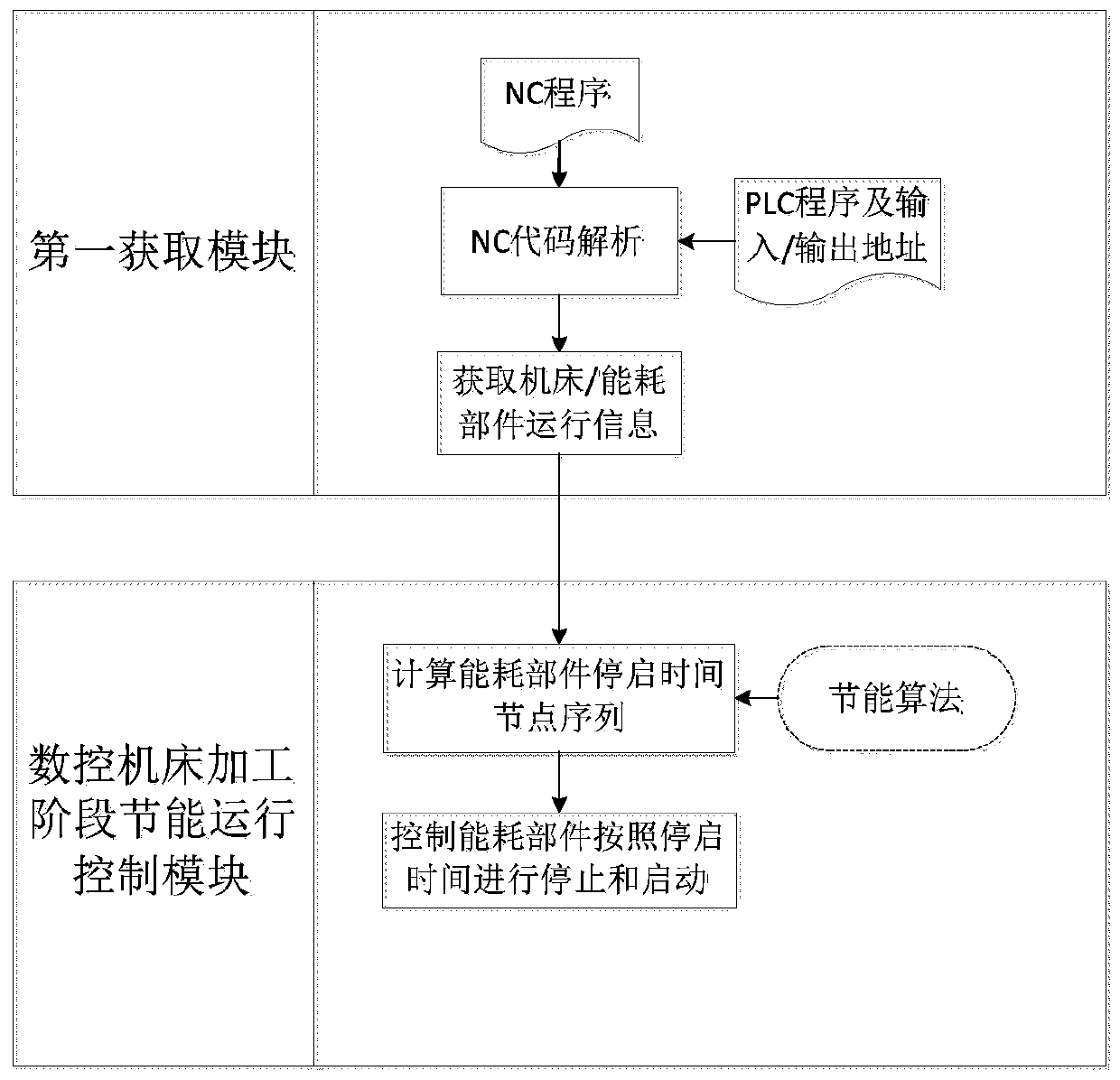

A technology of CNC machine tools and operating methods, which is applied in the direction of control/regulation systems, general control systems, digital control, etc., and can solve problems such as energy waste and immature energy-saving methods for CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

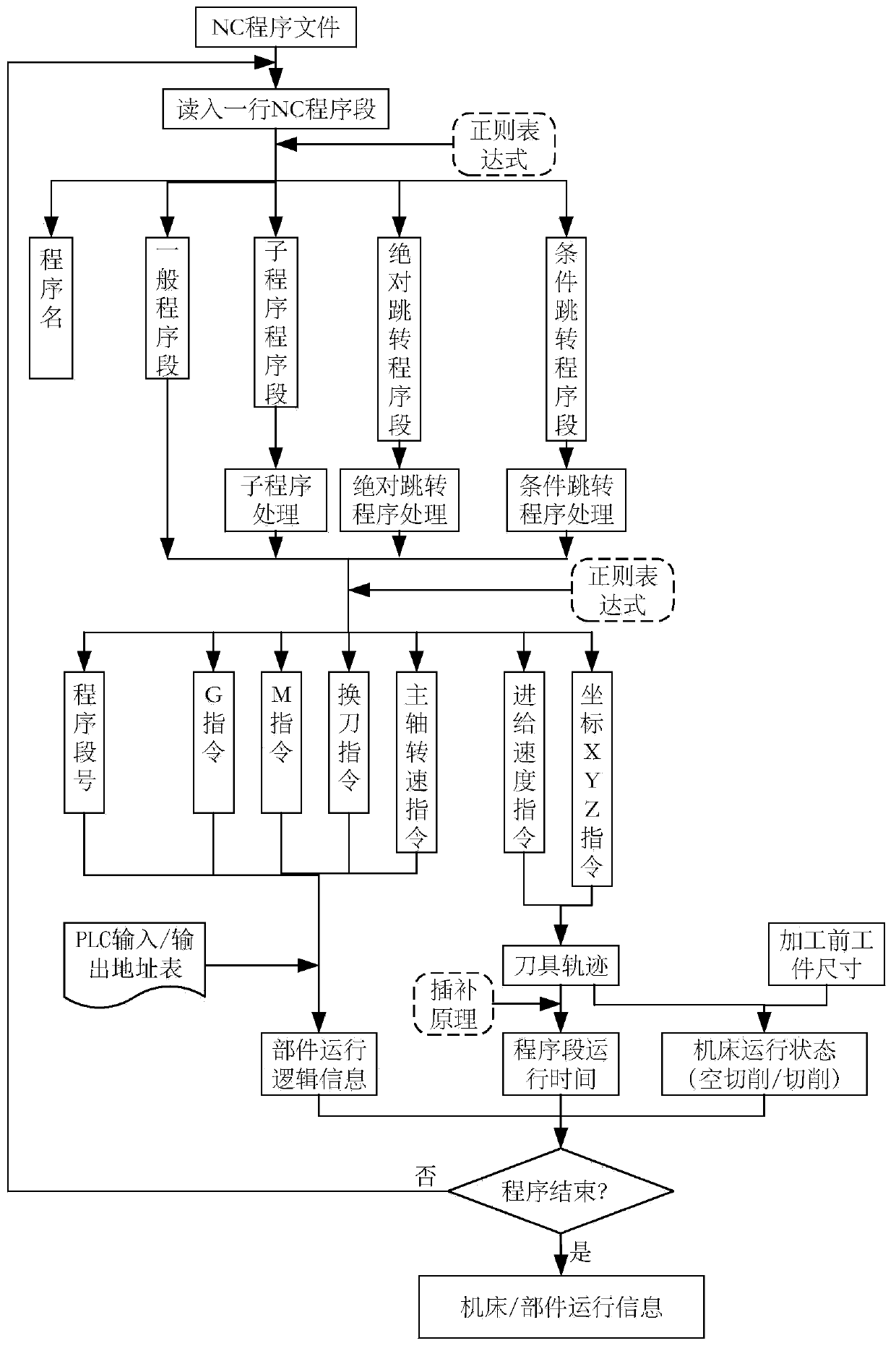

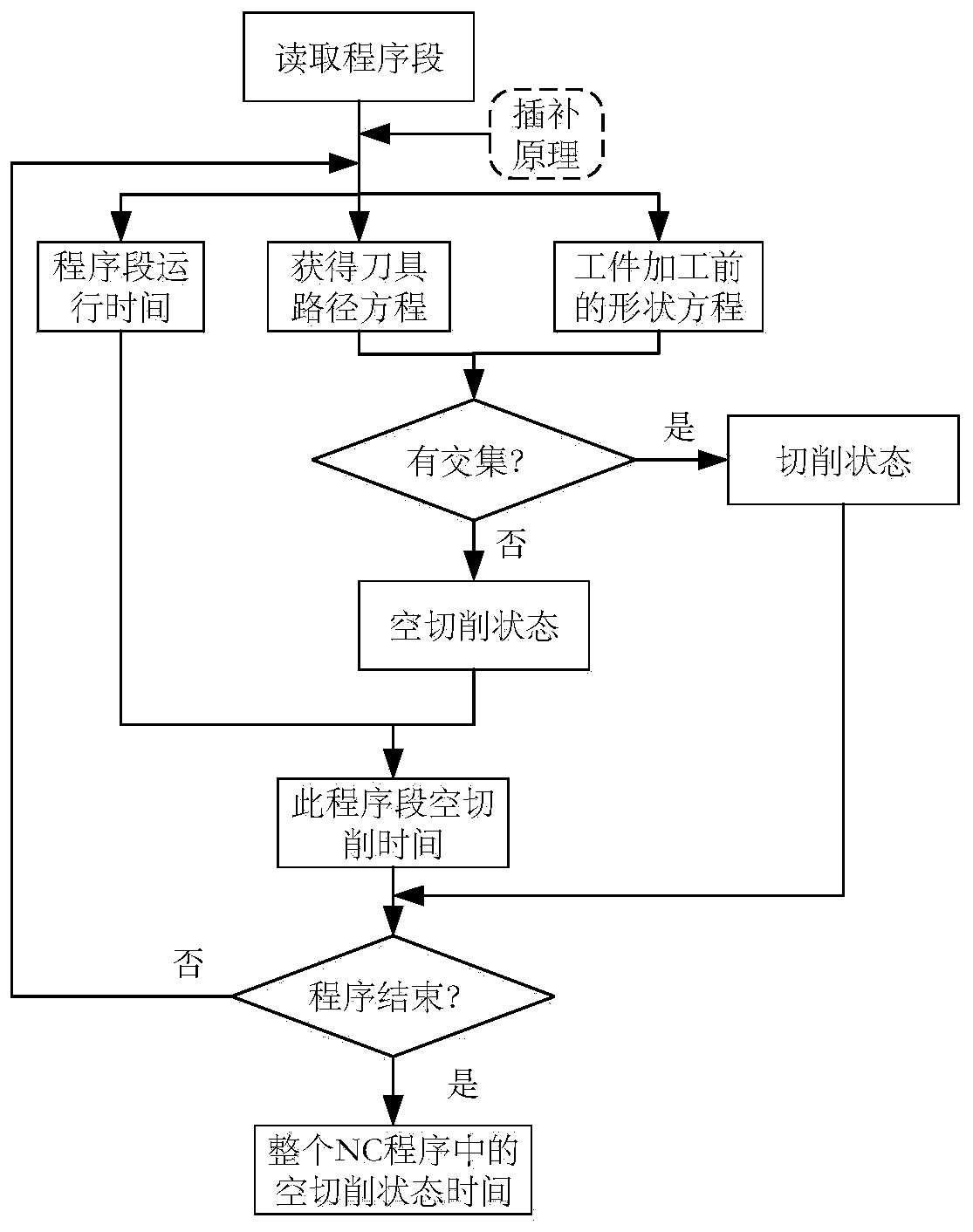

Method used

Image

Examples

example

[0138] Concrete example: the example numerical control machine tool is the numerical control machining center C.B.Ferrari MTS. Taking the numerical control code of a certain guide rail part as an example, adopt the energy-saving operation method and system of the machining stage in the operation process of the numerical control machine tool provided by the present invention to process the numerical control machine tool C.B.Ferrari MTS stage energy saving applications. The device for measuring the power of CNC machine tools is HIOKI 3390 power analyzer.

[0139] Acquisition of Energy Consumption Data of NC Machine Tool Components

[0140] The power data of energy-consuming components of CNC machine tools are shown in Table 2 and Table 3

[0141] Table 2 Power and function of main energy-consuming components of CNC machine tool C.B.Ferrari MTS

[0142] Part Name Average power (kW) Features Spindle 12 Provide cutting motion Feed axis (X, Y, Z, A, B, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com