Grounding wire applied to insulated conductor

A technology of insulated wires and grounding wires, applied in the direction of fastening/insulating connectors, conductive connections, connections, etc., can solve the problems of reducing the timeliness of emergency repairs, expanding the scope of power outages, and increasing the time for emergency repairs, so as to reduce the scope of power outages and ensure personal safety. The effect of safety and time-saving repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

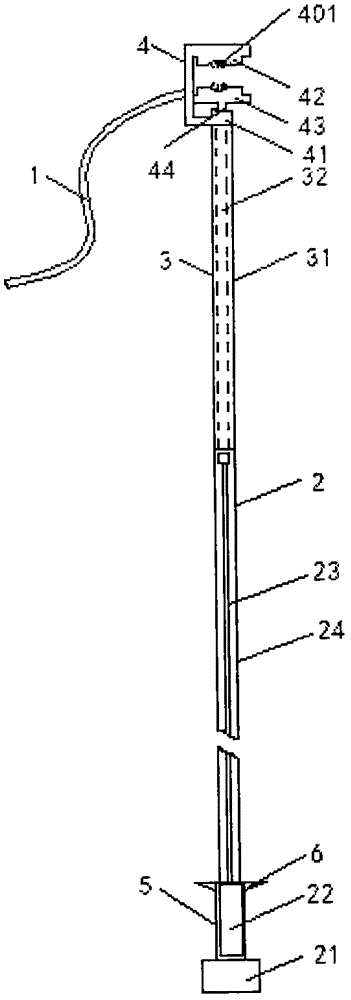

[0021] This embodiment provides a grounding wire applied to insulated wires, such as figure 1 As shown, it includes a ground wire 1, a hydraulic power assembly 2, a transmission assembly 3, and a puncture assembly 4. The hydraulic power assembly 2 is connected to the transmission assembly 3, and the transmission assembly 3 is connected to the puncture assembly 4. The puncture assembly The assembly 4 is connected to the ground wire 1, and the ground wire 1 is connected to the ground; the hydraulic power assembly 2 is used to provide driving force for the transmission assembly 3, and the transmission assembly 3 is used to provide power for the puncture assembly 4 Conduction, so as to drive the piercing component 4 to pierce or break away from the insulation layer of the insulated wire.

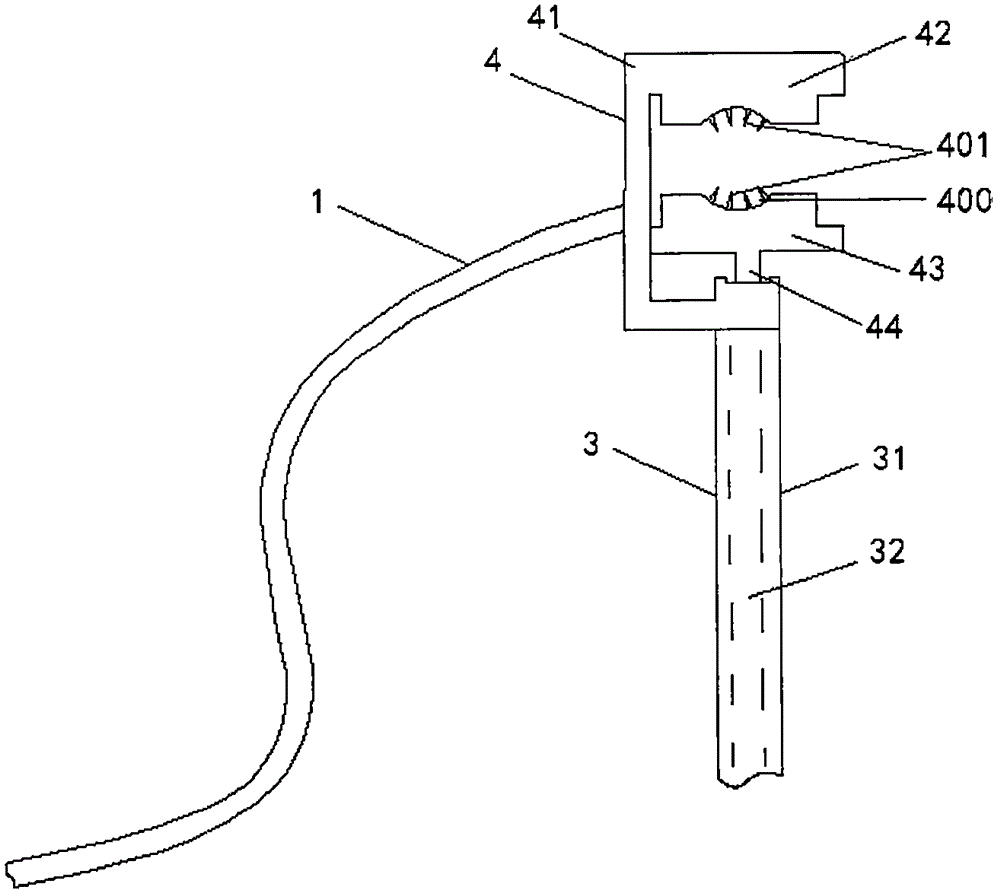

[0022] Among them, such as figure 2 As shown, the puncture assembly 4 includes a wire fixing frame 41, a first puncture part 42, a second puncture part 43, and a jack 44. The outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com