Pure electric logistics vehicle power line seal connection structure

A power cord sealing and connection structure technology, applied in vehicle connectors, connections, two-part connection devices, etc., can solve the problem of inconvenience of separating the drive motor and power supply, and achieve the phenomenon of not easy to fall off or poor electrical contact, and shock isolation effect. good performance, tightness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

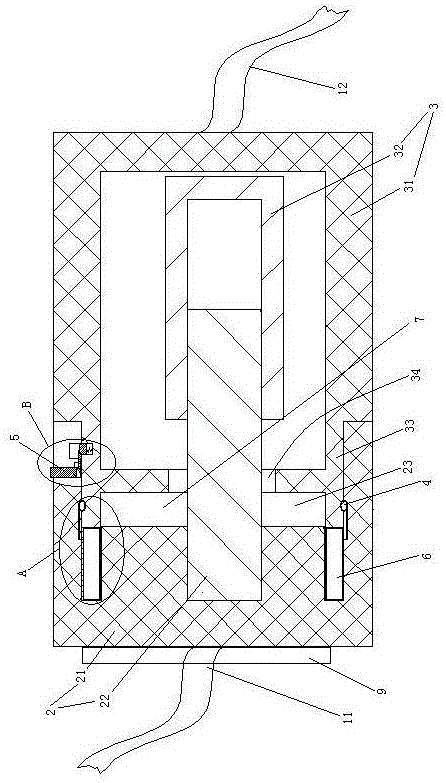

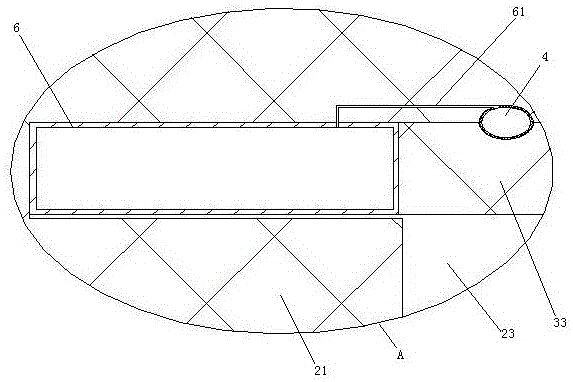

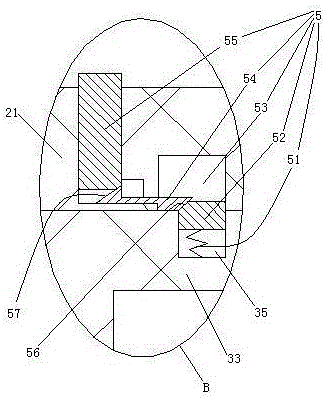

[0044] Embodiment one, see figure 1 , a pure electric logistics vehicle power cord sealing connection structure, including the power cord. The power cord comprises a first section 11 and a second section 12 . One end of the first section 11 is provided with a plug 2 . The plug 2 includes an insulating plug shell 21 and a conductive pin 22 . The plug housing 21 is provided with a vibration isolation pad 9 . The plug shell 21 is sealed and connected with the first section, that is, the joint between the first section and the plug shell is sealed. The plug housing 21 is provided with a connection hole 23 . The conductive plug 22 is disposed in the connection hole 23 . The conductive plug 22 is electrically connected with the first segment 11 . One end of the second section 12 is provided with a socket 3 . The socket 3 includes an insulating socket shell 31 and a conductive socket 32 inside the socket shell. The socket housing 31 and the second section 12 are hermeticall...

Embodiment 2

[0071] Embodiment two, the difference with embodiment one is:

[0072] see Figure 13 , the inflatable sealing ring 4 includes an inflatable inner ring 42 and an inflatable outer ring 41 sleeved outside the inflatable inner ring 42 . Only the inflatable inner ring 42 communicates with the air supply tank 6 through the communication pipe 62 . Gas and red toner are filled between the inflatable inner ring 42 and the inflatable outer ring 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com