Jig structure suitable for assembly of magnetic tile

A technology of magnetic tiles and jigs, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as large labor costs, inability to realize automated production, and irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

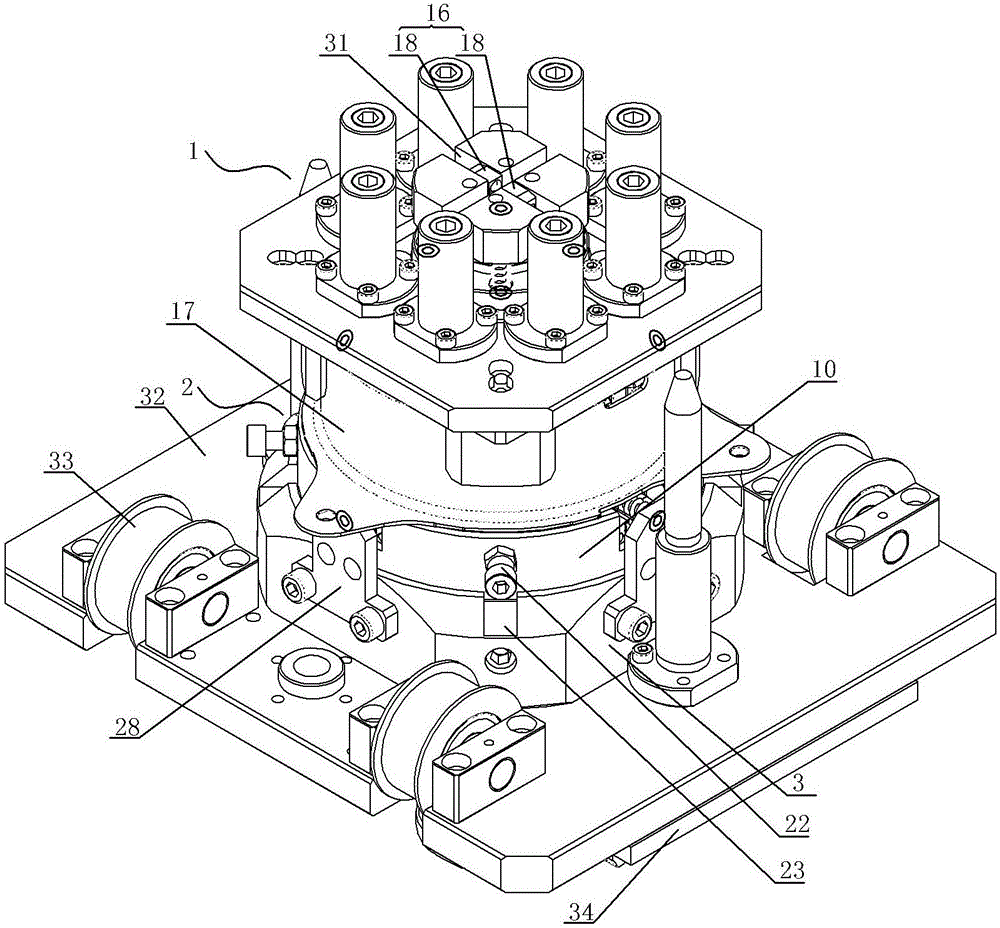

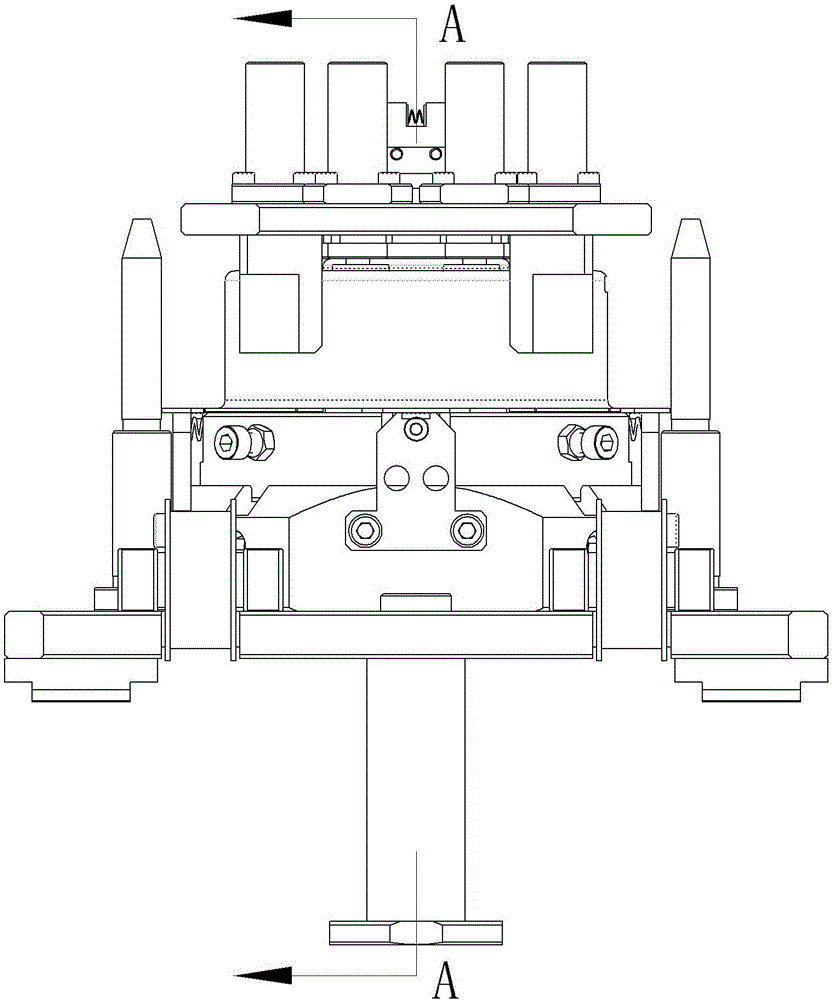

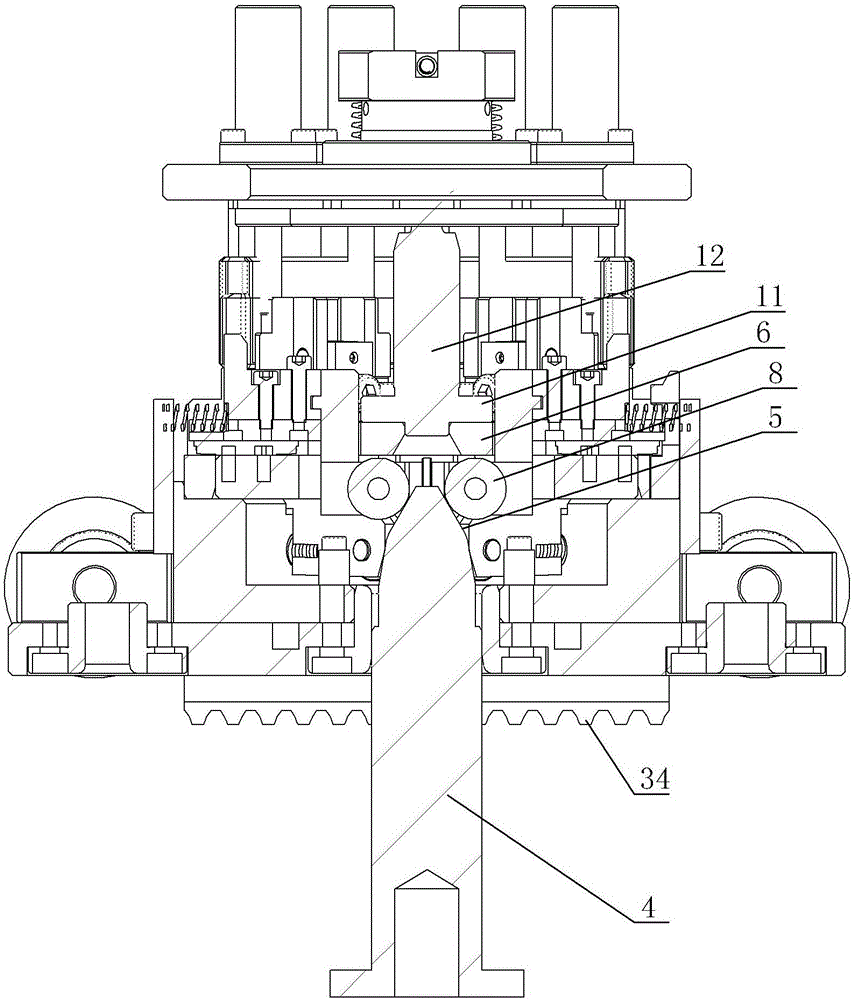

[0022] A fixture structure suitable for magnetic tile assembly, see figure 1 : It includes an upper jig 1 and a lower jig 2, the lower jig 2 includes a base 3, an upper positioning structure, and a central positioning shaft 4, the central positioning shaft 4 protrudes above the base 3, and the upper part of the central positioning shaft 4 is closed upwards The arc transition structure 5, the upper positioning structure includes several magnetic tile positioning blocks 6 of circular arc structure, the magnetic tile positioning blocks 6 are combined to form a circular structure, and the adjacent magnetic tile positioning blocks 6 are provided with magnetic tile positioning spacers 7. The bottom inner end of each magnetic tile positioning block 6 is provided with a first guide wheel 8, and the inner end of each first guide wheel 8 is close to the outer end surface of the circular arc transition structure 5 of the central positioning shaft 4, and each magnet The outer bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com