A conveying line arrangement structure of an automatic assembly line for an automobile motor rotor

A motor rotor and conveying line technology, applied in the field of conveying line arrangement structure, can solve the problems of poor uniformity of incoming materials for product parts, inability to realize automatic production, irregularity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

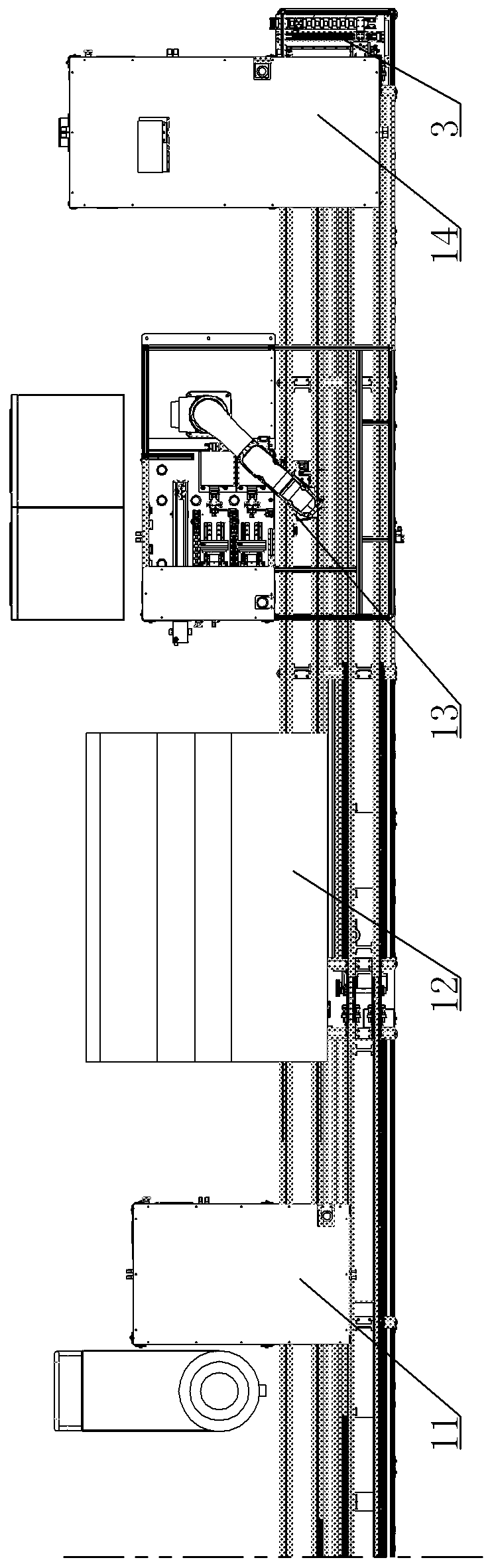

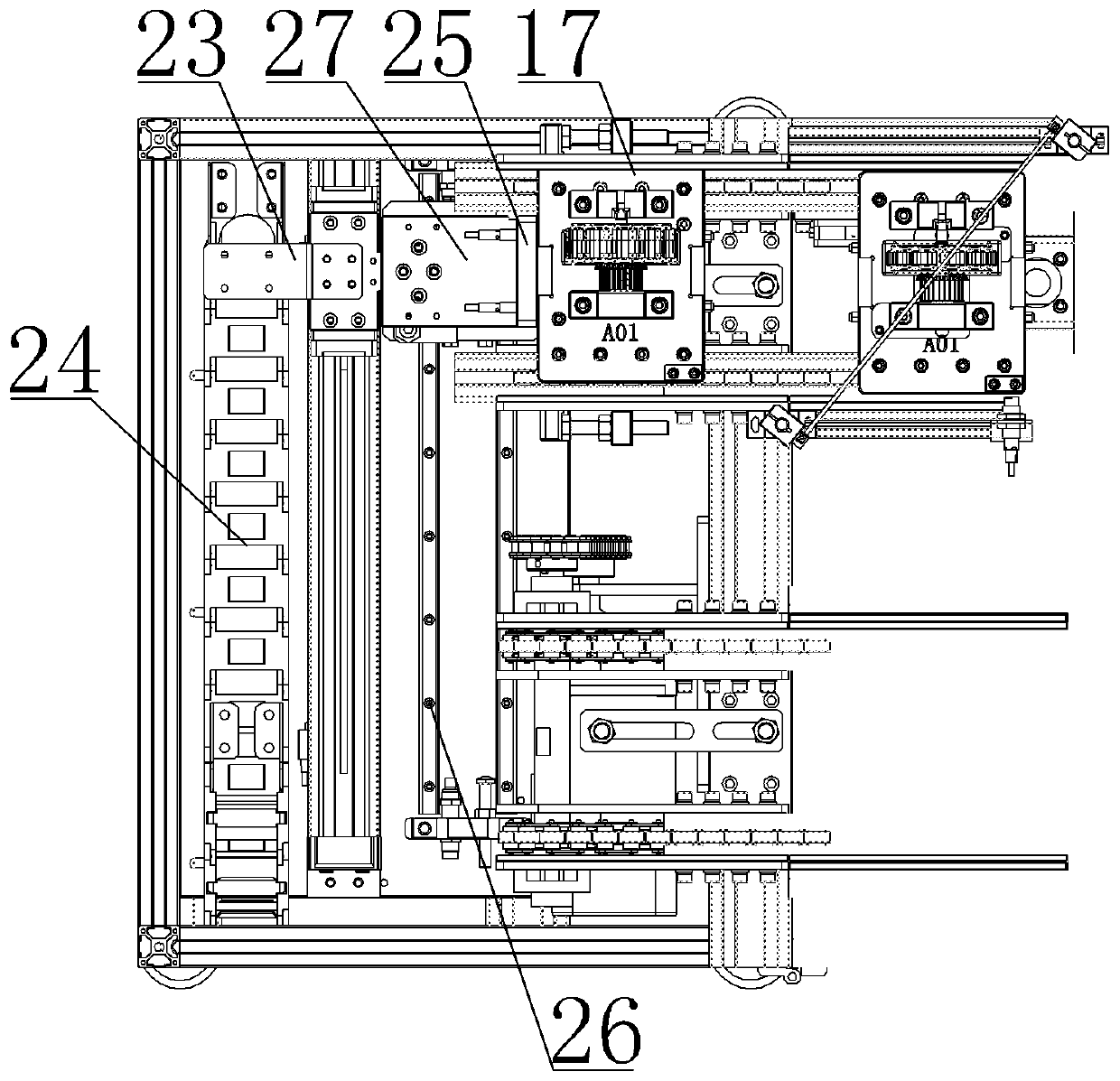

[0016] A conveying line arrangement structure of an automatic assembly line for automobile motor rotors, see Figure 1 to Figure 4 : It includes a frame 1, two parallel linear tracks are arranged on the frame 1, and the two ends of the two parallel linear tracks are respectively provided with a front end transition structure 2 and a rear end transition structure 3, and one of the linear tracks is for conveying The product conveying line 4 of the product, and the other straight line is the return line 5 that conveys the tray back to the beginning of the production line. The product conveying line 4 is arranged with a feeding station 6, a welding station 7, and a shaft along the product conveying direction. Press-in station 8, copper wire shaping station 9, turning station 10, cleaning station 11, dynamic balance test station 12, characteristic inspection station 13, rear bearing press-in station 14, product conveying line 4 each The positions of each station are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com