A conveyor line structure suitable for magnetic tile assembly

A technology of conveying lines and magnetic tiles, which is applied in the direction of electromechanical devices, electrical components, manufacturing stator/rotor bodies, etc., and can solve the problems of poor uniformity of incoming materials for product parts, inability to realize automatic production, irregularities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

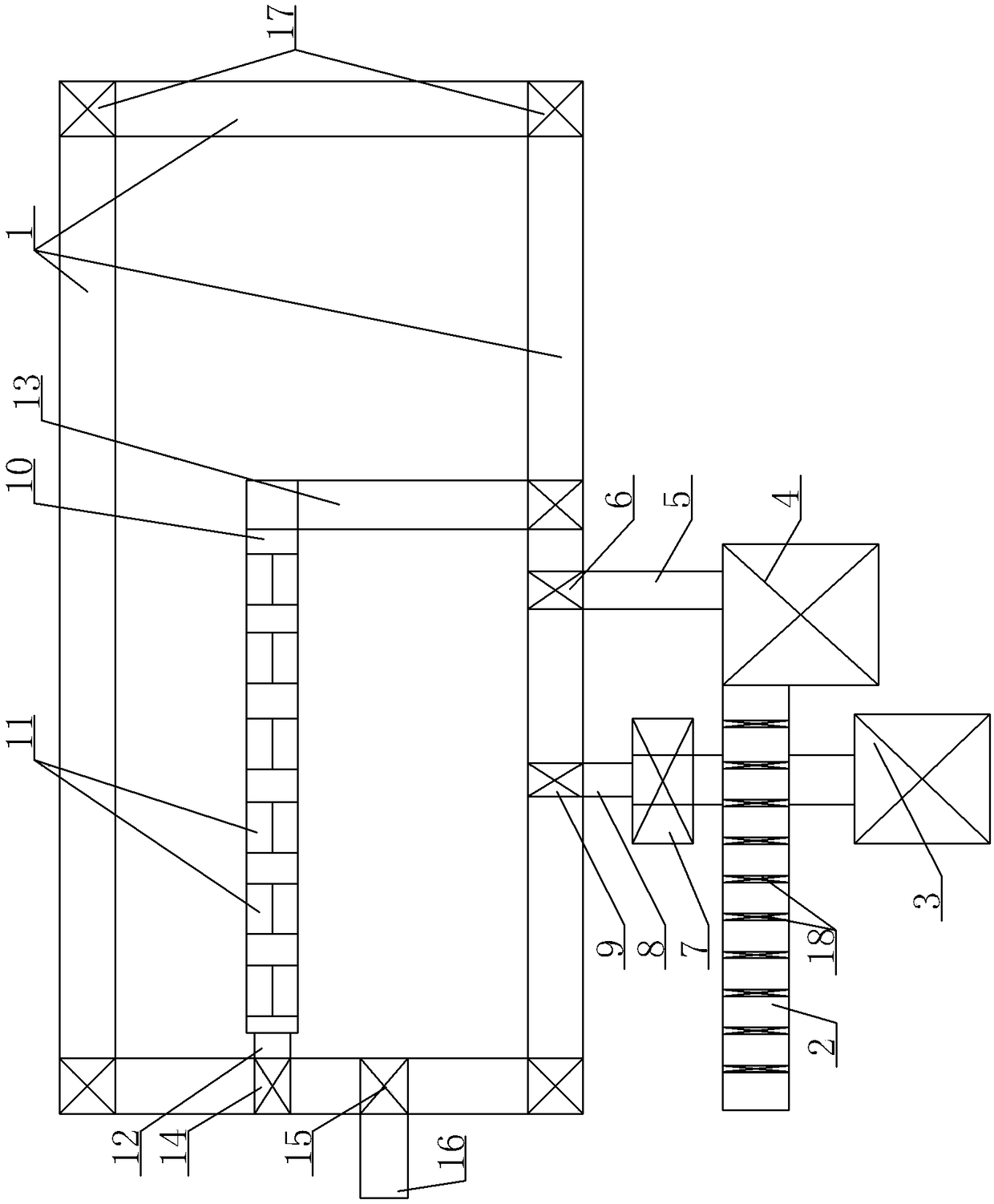

[0012] A conveyor line structure suitable for magnetic tile assembly, see figure 1 : It includes a circular and closed jig curing production line 1, one side of the jig curing production line 1 is provided with an organic casing feeding line 2, and the outer side of the casing feeding line 2 is provided with a magnetic tile distributor 3, and the curing A lower jig (not shown in the figure) is installed on the track corresponding to the solidification production line 1, an organic shell coating machine 4 is arranged behind the shell feeding line 2, and the output end of the shell coating machine 4 is set There is a first conveying manipulator 5. The first conveying manipulator 5 puts the coated casing onto the lower jig at the corresponding position of the jig curing production line 1. This position is the casing assembly and loading station 6, and the magnetic The output end of tile splitting machine 3 is provided with magnetic tile assembly mold 7, and magnetic tile assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com