Line forming method adopting printing means

A technology of circuit and means, applied in the direction of conductive pattern formation, can solve the problem of difficult to improve conductivity, and achieve the effect of no pollution and precise production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

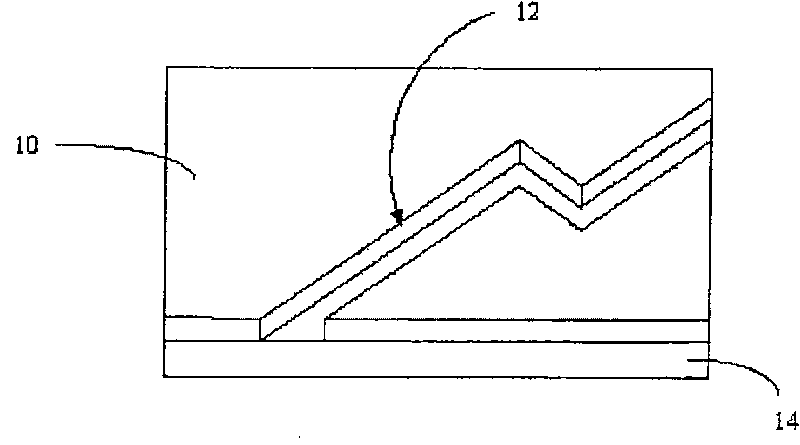

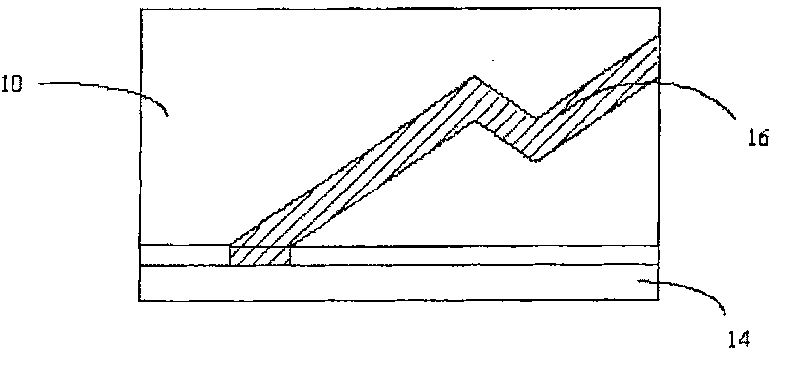

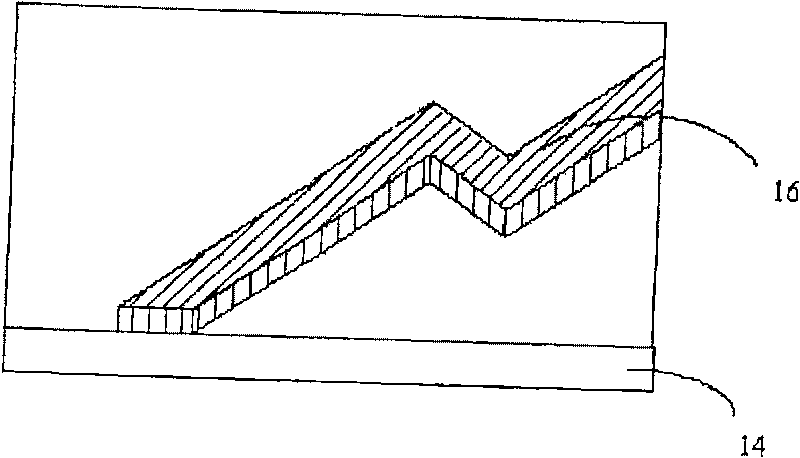

[0023] see Figure 1A-1D , Figure 1A-1D It is a schematic diagram of the circuit forming method using printing means in the present invention. Such as Figure 1A-1D As shown, the present invention mainly does not use etched copper foil to form lines, but uses such as Figure 1D The adhesive layer 16 shown adheres the metal powder and solidifies the metal powder to form the circuit 18 , so as to provide the convenience of coating like the conductive adhesive, but better than the conductive effect of the conductive adhesive.

[0024] In simple terms, the present invention is as follows Figure 1A A patterned screen 10 (having a traversing pattern 12 relative to a predetermined line), a substrate 14 is provided as shown, and as shown in FIG. Figure 1B As shown, the patterned screen 10 is used to transfer the adhesive to the substrate 14, and a patterned adhesive layer 16 is formed on the substrate 14, as shown in FIG. Figure 1C shown. Then, apply metal powder to the adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com