Knapsack hybrid rice seed production pollinating machine and pollinating method thereof

A hybrid rice and pollinator technology, applied in the field of agricultural machinery, can solve the problems of poor rope pulling effect, complicated procedures, high labor intensity, etc., and achieve the effects of convenient operation, uniform pollination, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and example. The technical features in the following examples can be combined with each other if there is no conflict.

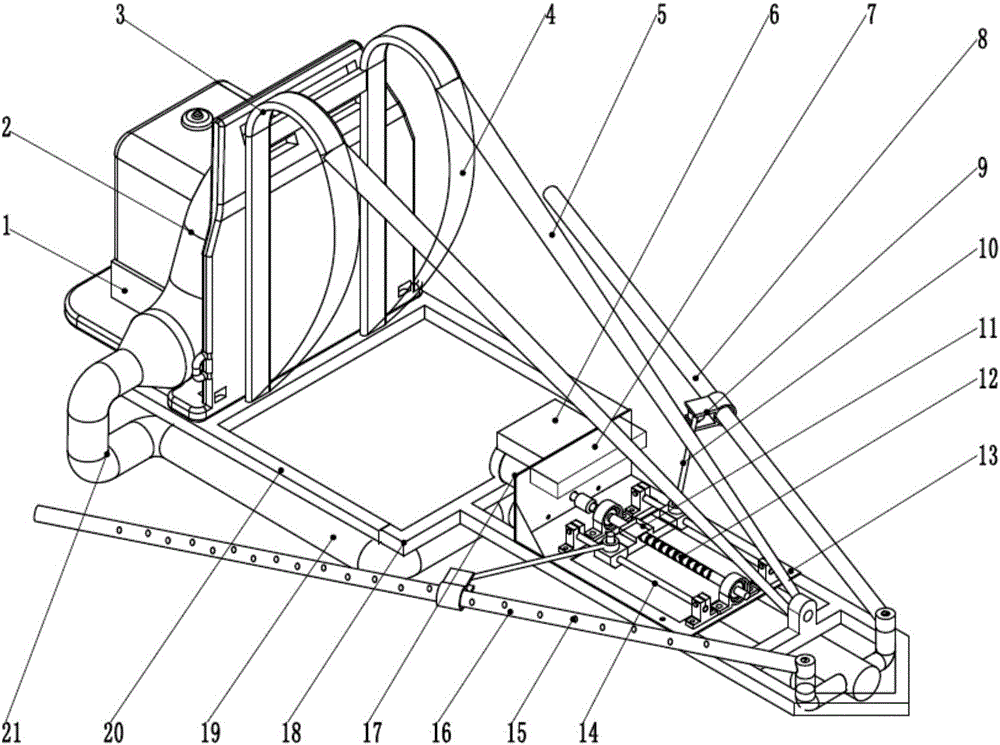

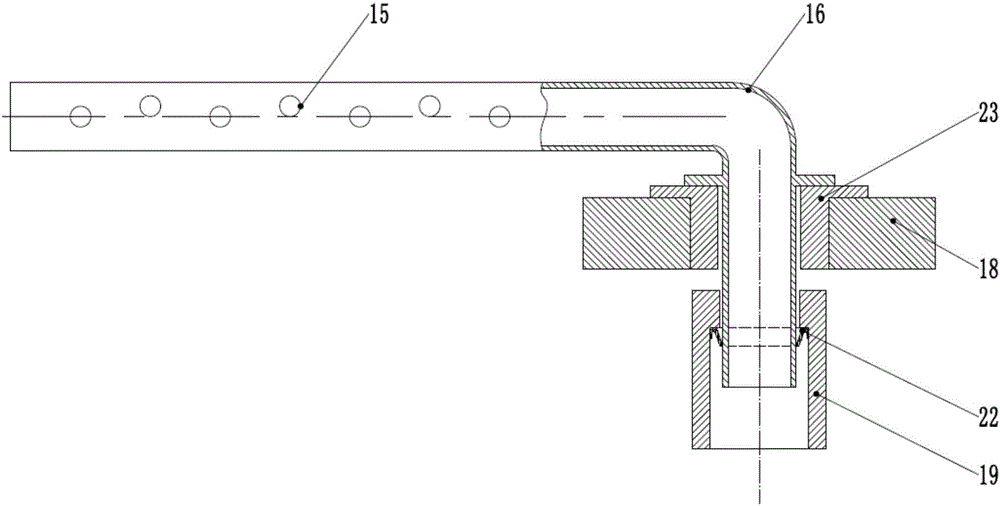

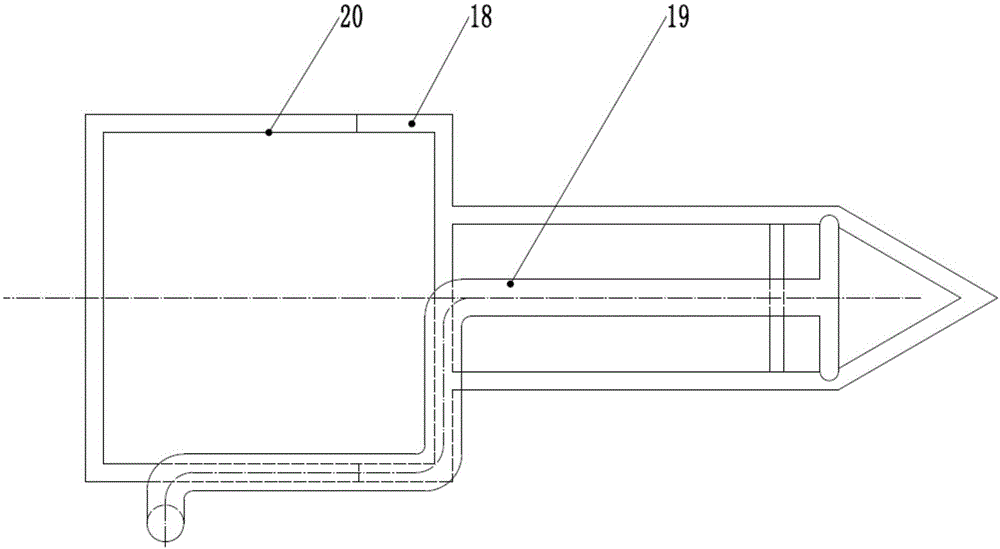

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the knapsack hybrid rice seed pollination machine comprises a micro gasoline engine 1, a blower 2, a damping back pad 3, a strap 4, a balance belt 5, a driver 6, a storage battery 7, a left-click ear air blowing pipe 8, a fixed block 9, and a Rod 10, reciprocating slider 11, screw mandrel 12, support plate 13, guide rod 14, air blow hole 15, right-click ear air blow pipe 16, motor 17, bracket 18, bellows 19, frame 20, conduit 21, seal Bearing 22, self-lubricating bearing 23; micro-gasoline engine 1 and blower 2 are fixed at the rear of frame 20, damping back pad 3 is fixed at the middle of frame 20, and the power output shaft of micro-gasoline engine 1 is coaxially connected with the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com