Production process of body of two-piece can

A production process, two-piece can technology, applied in the field of two-piece can body production technology, can solve problems such as cracking and straining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

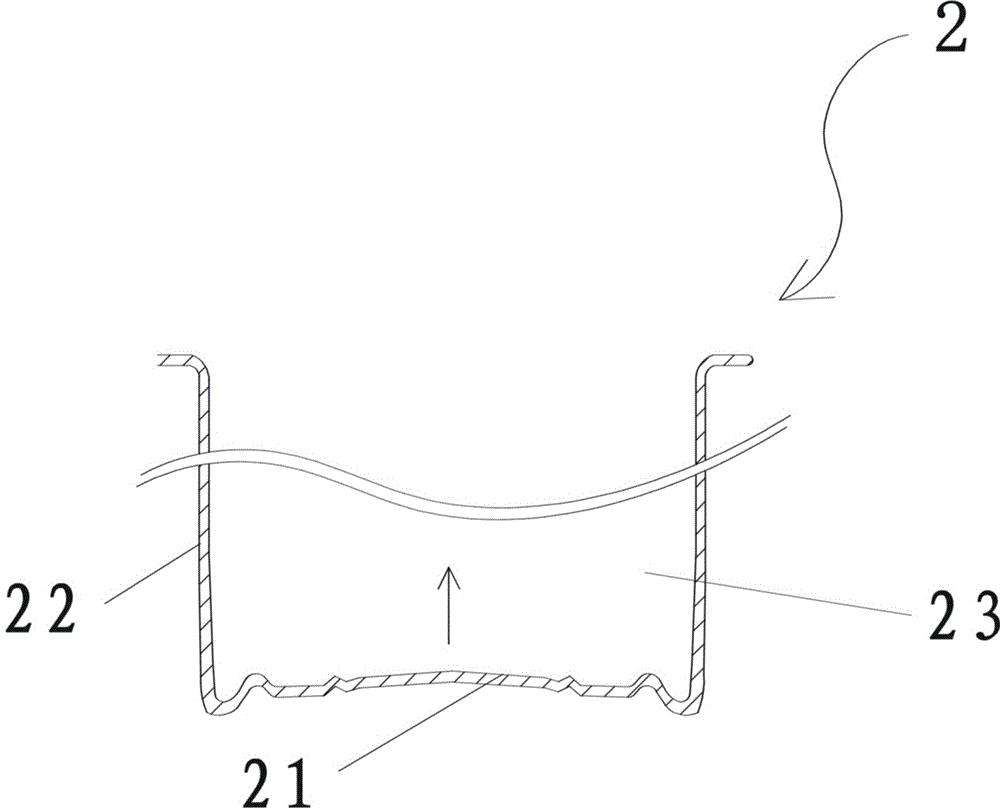

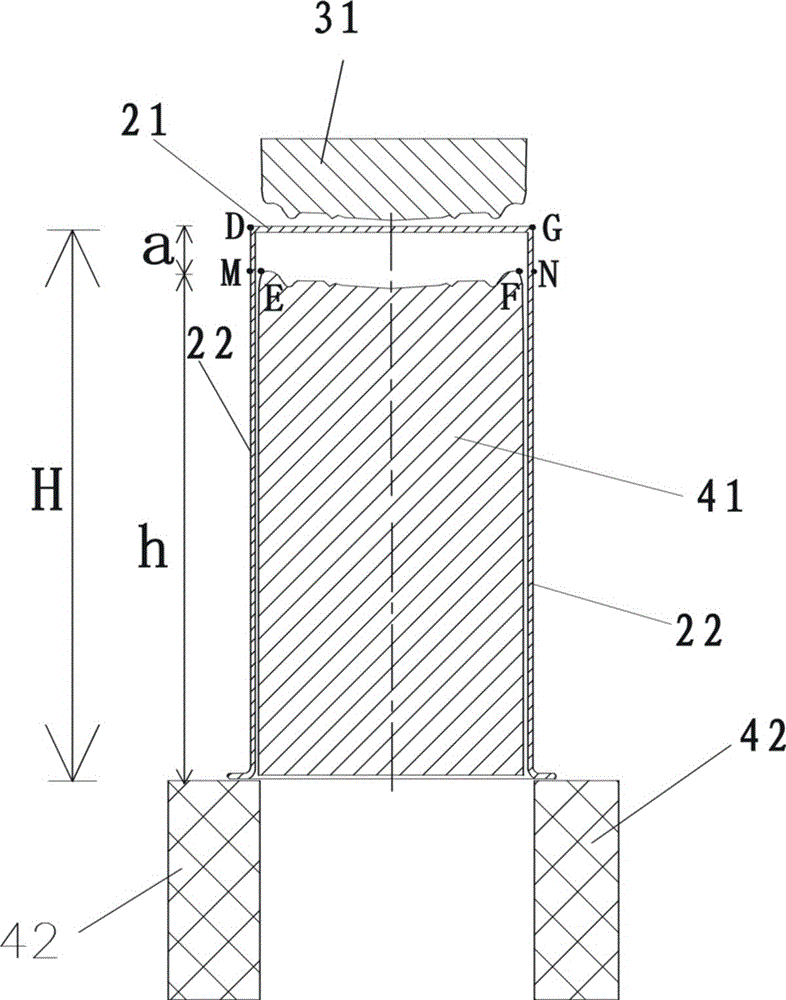

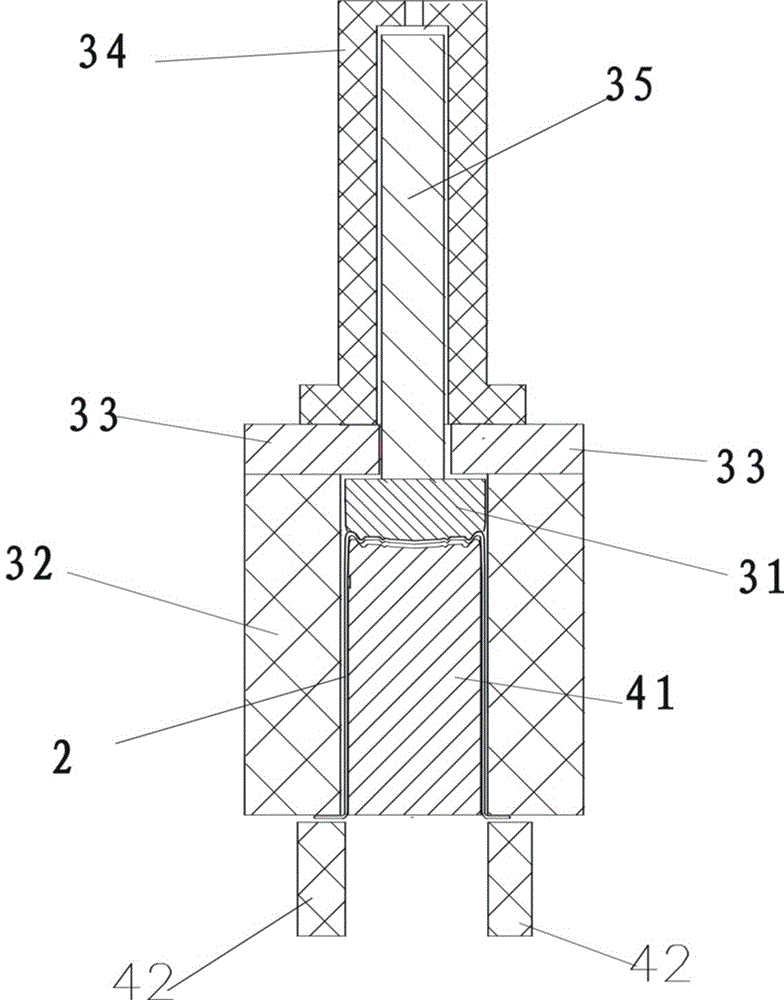

[0034] A two-piece can body production process, the design value of the tank wall height of the finished can is h, and the bottom punching equipment used includes an upper die assembly 3 and a lower die assembly 4, wherein the lower die assembly 4 Including a lower mold core 41 and an annular spacer 42, the lower mold core 41 is cylindrical, the upper surface of the lower mold core 41 is formed with an annular groove and an annular rib required for stamping the tank bottom, the lower mold core 41 is fixed, The annular spacer 42 is set on the periphery of the lower die core 41 and can move vertically; The mold core 31 is cylindrical, and the lower surface of the upper mold core 31 is formed with annular grooves and annular ribs required for stamping the bottom of the tank. The position of the upper mold core annular groove corresponds to the position of the lower mold core annular rib. The position of the annular rib of the upper mold core matches the position of the annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com