Internal combustion locomotive radar installing and positioning method

A technology for installation and positioning of internal combustion locomotives, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems affecting the normal operation of locomotives, achieve the effect of ensuring installation quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

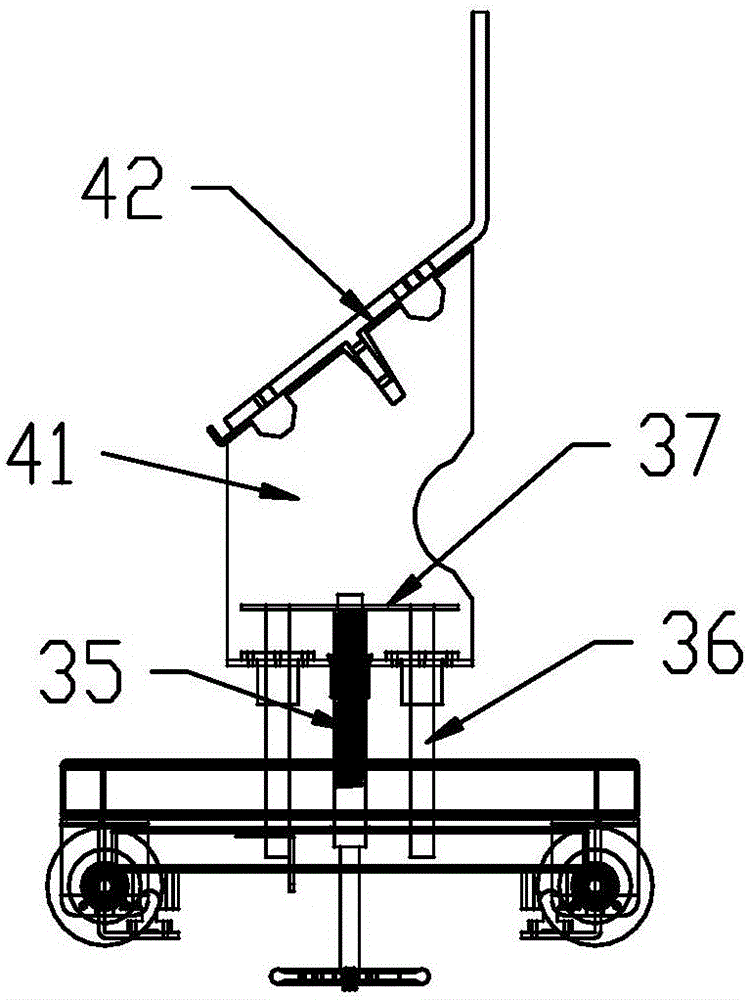

[0027] In the present invention, the structure of parts of the Harmony series diesel locomotive radar installation and positioning device is divided into four parts, including wheel assembly, base assembly, main body sliding and rising part assembly, and support part assembly.

[0028] Part 1: Wheel Assembly

[0029]

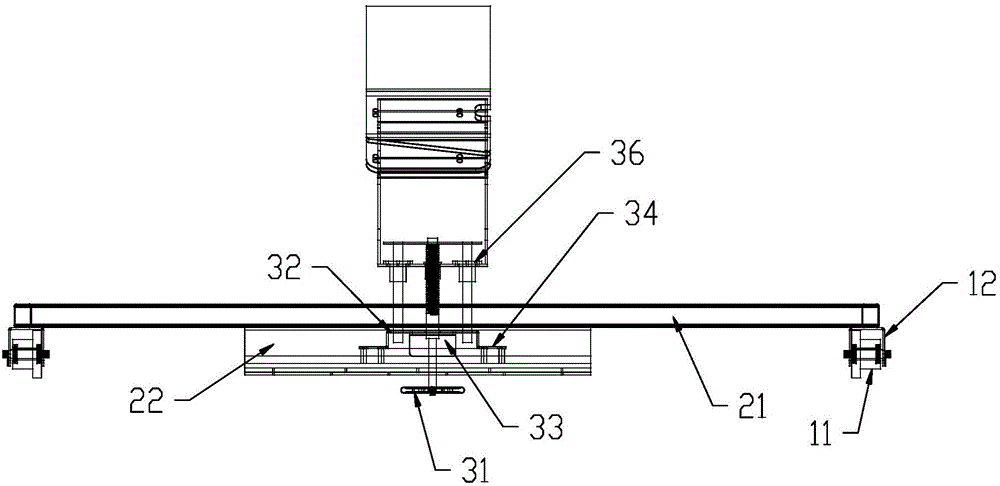

[0030] The wheel assembly consists of four groups distributed at the four corners of the base assembly. The wheel 11 is assembled on the wheel clamp 12 by cotter pins, and the wheel clamp 12 is welded on the four diagonal sides of the bottom of the square tube base 21 .

[0031] Part Two: Base Assembly

[0032]

[0033] Square tube base 21 is rectangular, and after slideway 23 is welded on the base support plate 22, base support plate 22 is welded on the square tube base 21, and main body sliding and rising part assembly part just can move certain dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com