Mould for manufacturing T-shaped pile

A mold and forming mold technology, which is applied in the direction of manufacturing tools, mold auxiliary parts, ceramic molding machines, etc., can solve the problems of not being able to produce T-shaped prefabricated piles, and achieve the effects of easy implementation, reduced production costs, and improved steam curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

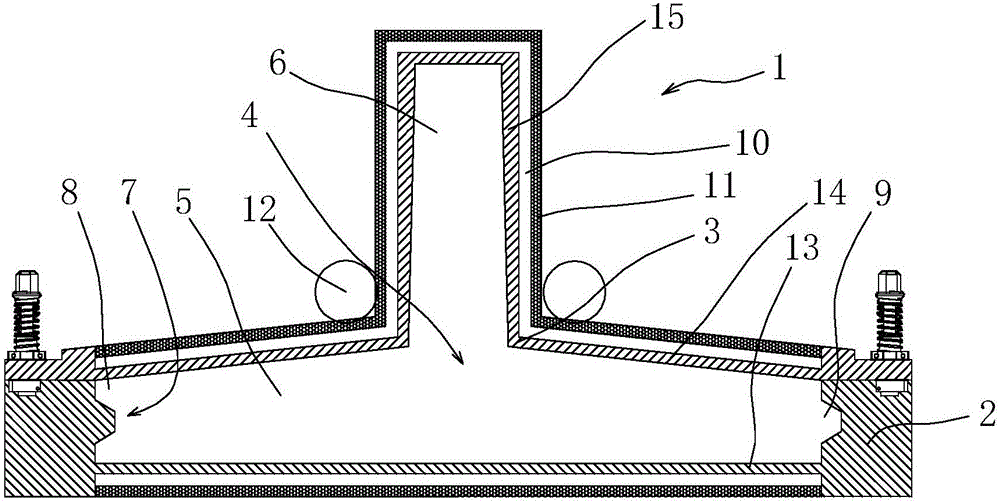

[0032] like figure 1 and figure 2 As shown, a mold for manufacturing T-shaped piles includes a mold body 1, and the mold body 1 includes a detachably connected plane forming mold assembly 2 and a convex letter forming mold assembly 3, and the inside of the mold body 1 has a shape of T. The font-shaped forming cavity 4, the forming cavity 4 includes a connecting pile forming cavity 5 and a supporting pile forming cavity 6 that communicate with each other, and the supporting pile forming cavity 6 is perpendicular to the connecting pile forming cavity 5 to form a T-shaped forming cavity 4.

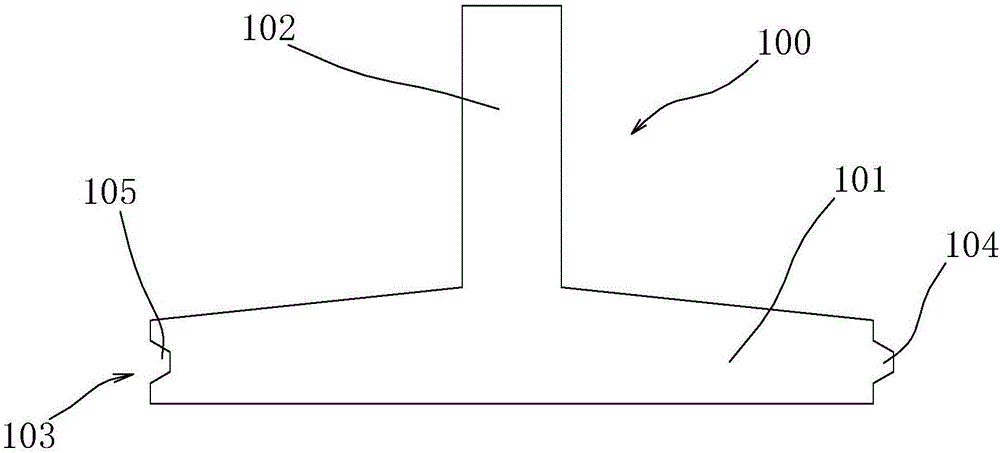

[0033] The mold provided in this embodiment is used to make image 3 The T-shaped pile 100 shown, the plane forming die assembly 2 and the convex forming die assembly 3 can be fixedly connected by mechanical connectors such as bolt pairs or clamping screws, which are easy to disassemble. figure 2 As shown, after the mechanical connector is loosened, the embossed forming mold assembly 3 ca...

Embodiment 2

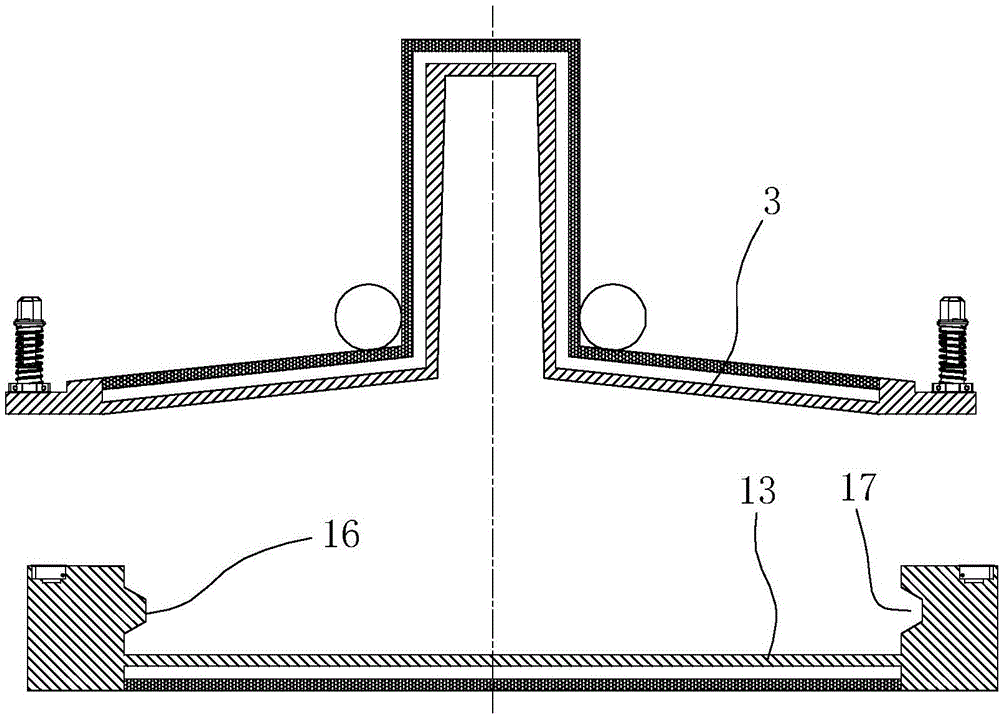

[0045] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 5 and Image 6 As shown, the forming convex strip 16 is detachably fixed on the plane forming die assembly 2, and the forming groove 17 is formed by connecting the plane forming die assembly 2 and the convex letter forming die assembly 3. Specifically, the forming concave The groove 17 is formed by connecting the plane mold 13 and the connecting pile forming mold 14 . With this structure, the size and shape of the connection groove 105 on the T-shaped pile 100 can be adjusted by disassembling the forming convex strip 16. By adjusting different plane molds 13 and connecting pile forming molds 14, forming grooves of different sizes and shapes can be obtained. Groove 17 has higher adaptability.

Embodiment 3

[0047] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 7 As shown, the plane forming die assembly 2 includes a plane die 13, and the embossing forming die assembly 3 includes a first frame 18, a second frame 19 and two embossing forming dies 20, and the two embossing forming dies 20 are symmetrical It is arranged on the first frame 18 and is hinged with the first frame 18, and the second frame 19 is fixed on the embossed character forming die 20, and the concave-convex forming mechanism 7 is hinged with the second frame 19 and can be connected with the plane forming die set Part 2 is a detachable fixed connection.

[0048] Described embossed character forming mold 20 comprises the connecting pile forming mold 14 that is positioned at connecting pile forming cavity 5 outer walls and the supporting pile forming mold 15 that is positioned at supporting pile forming cavity 6 outer walls, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com