A wind power blade mold root flange device and using method thereof

A wind turbine blade and flange technology is applied in the field of wind turbine blade mold root flange device, which can solve problems such as accident risk, damage to the root base, weaken the strength of the base, etc. Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

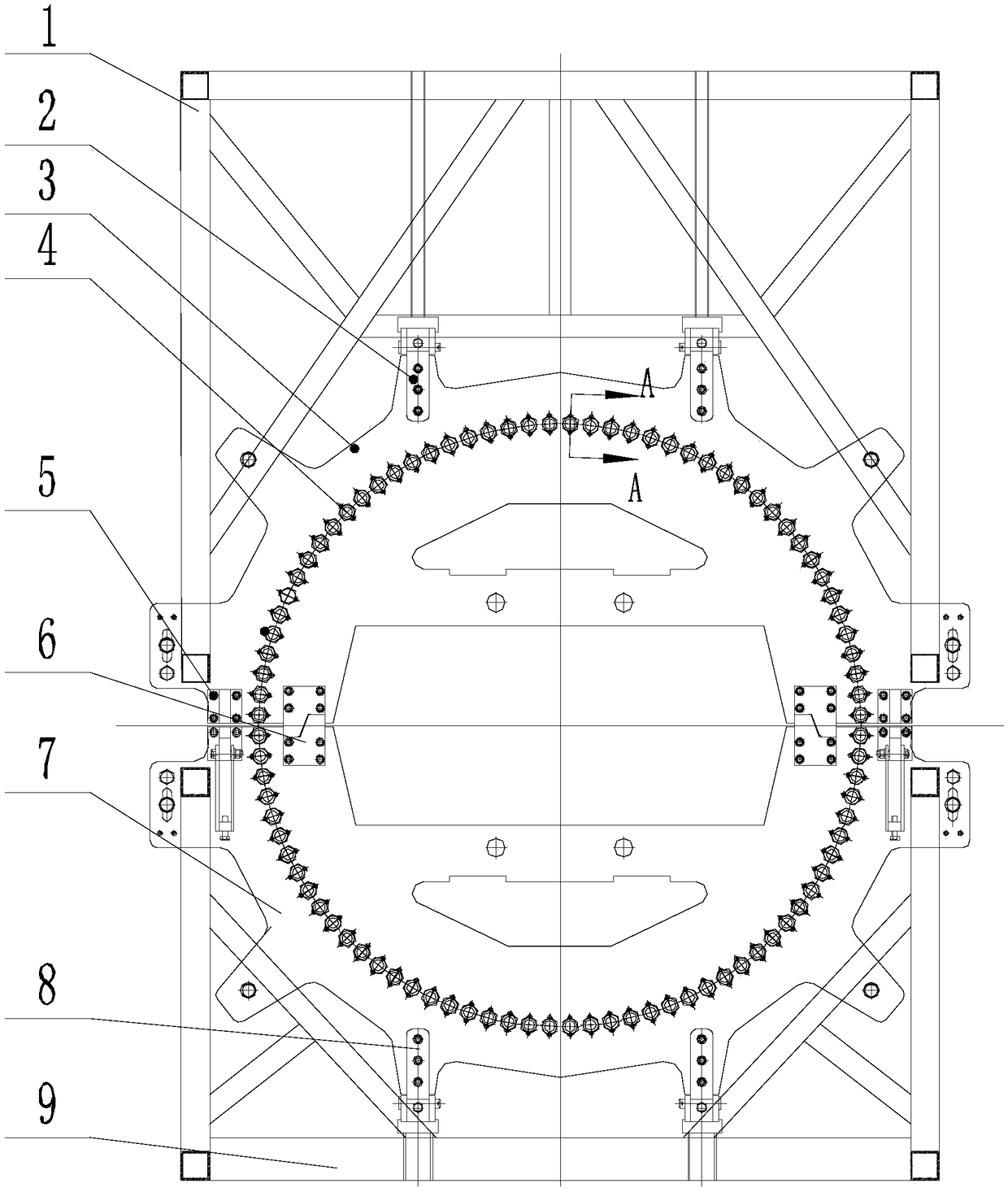

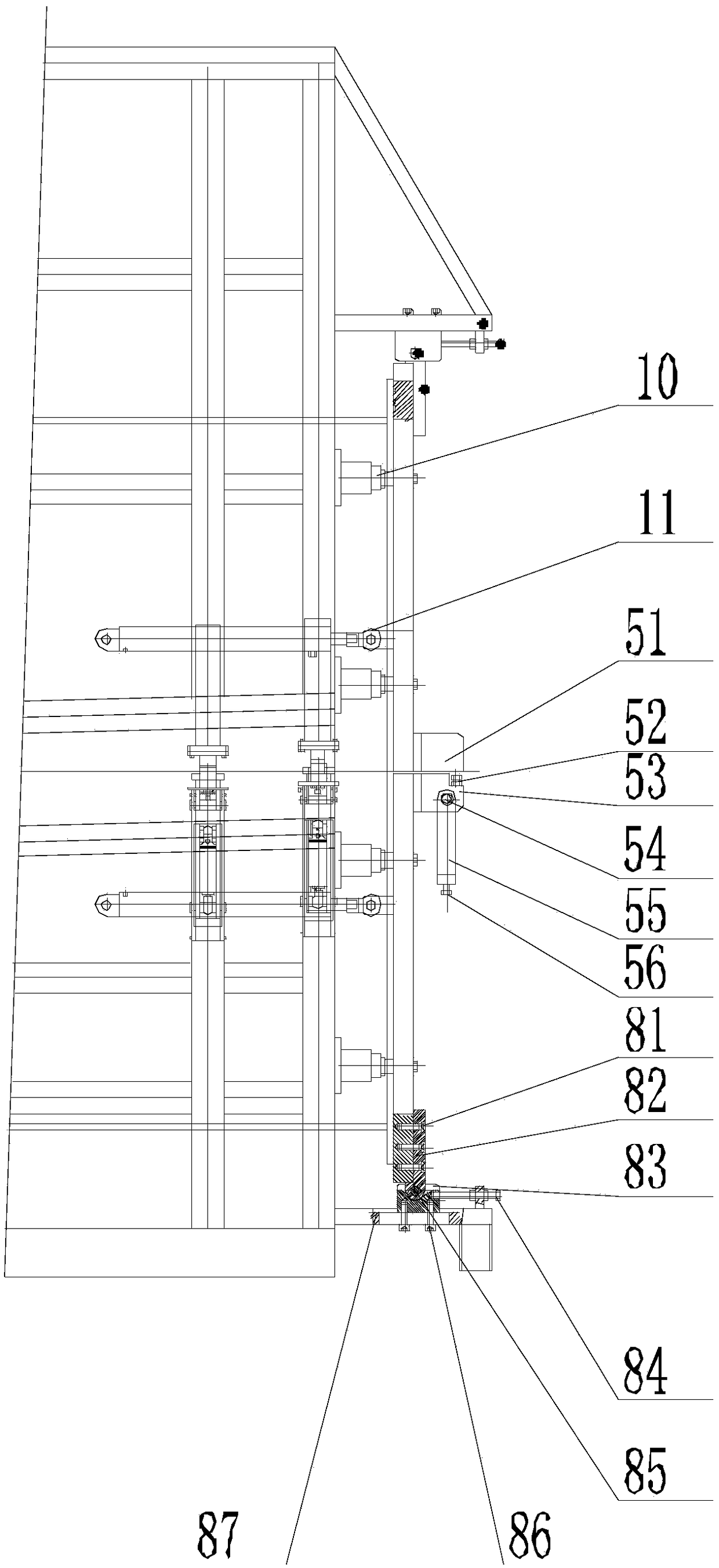

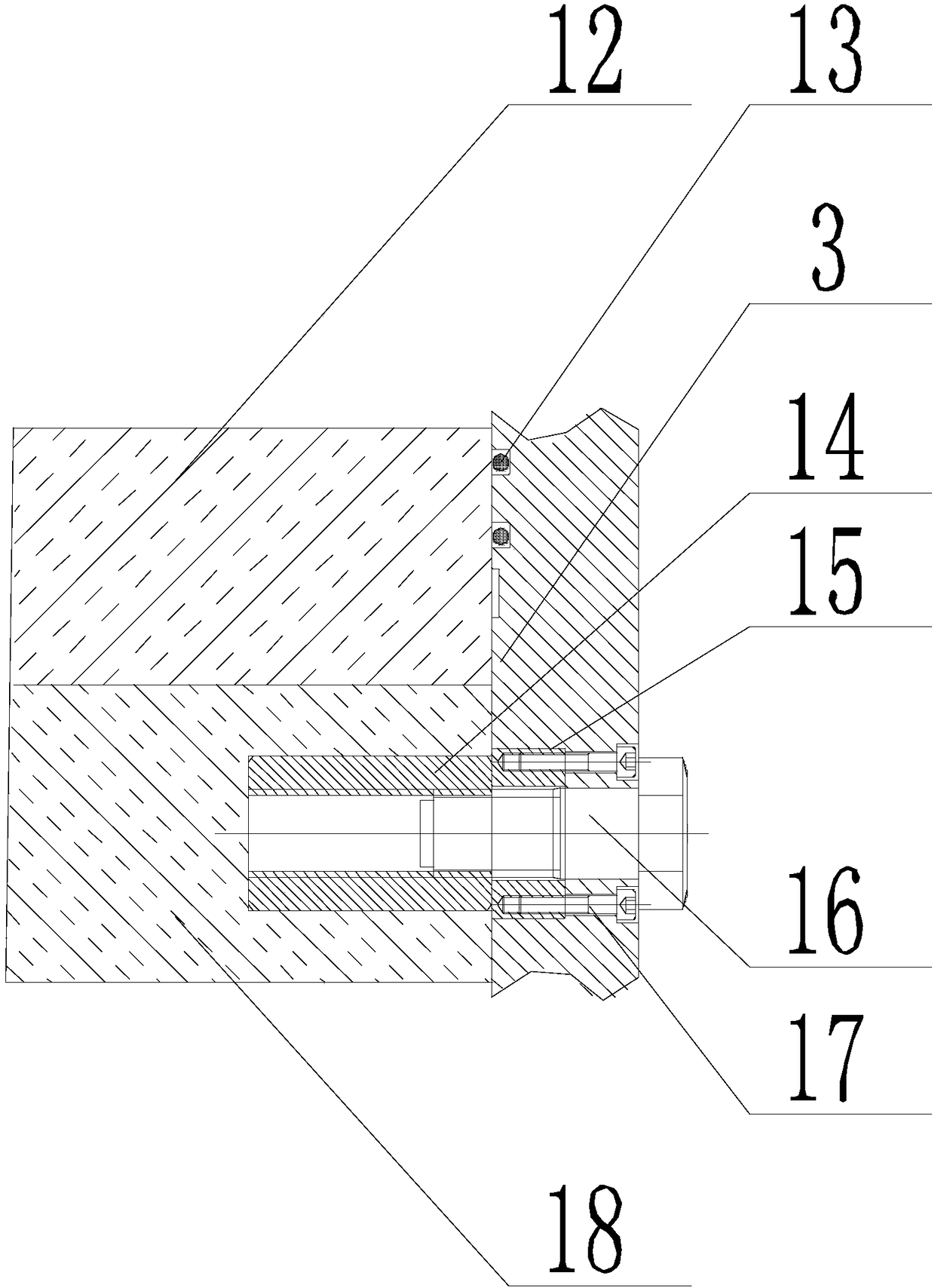

[0019] see Figure 1-3 , a flange device at the root of a wind power blade mold, comprising an upper mold steel flange 3, an overturning connection device, a lower mold steel flange 7, a pre-embedded bolt mechanism 4, a locking device 5, a positioning device 6, a positioning support device 10 and Overturning oil cylinder device 11, described overturning connecting device comprises the first overturning connecting device 2 and the second overturning connecting device 8, the upper die steel flange 3 and the lower die steel flange 7 are semicircular and the upper die steel flange 3 and the lower die steel flange The center of the mold steel flange 7 coincides, the two sides of the center of the upper mold steel flange 3 and the lower mold steel flange 7 are provided with a locking device 5, and the inner side of the locking device 5 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com