Closing Unit Used For Molding Machine And Molding Machine

A molding machine and machine base technology, which is applied in the field of molding machines, can solve the problems of plate parallelism and the parallelism of the half parts of the mold not reaching a sufficient degree, and achieve the effects of good adjustment or control, energy saving, and simple design structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are the common points of the embodiments:

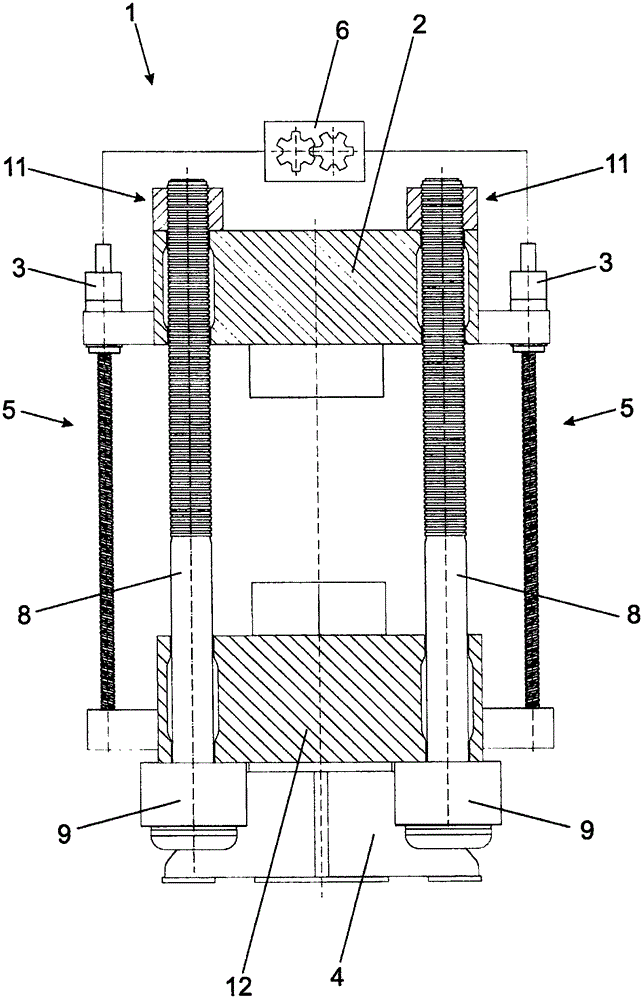

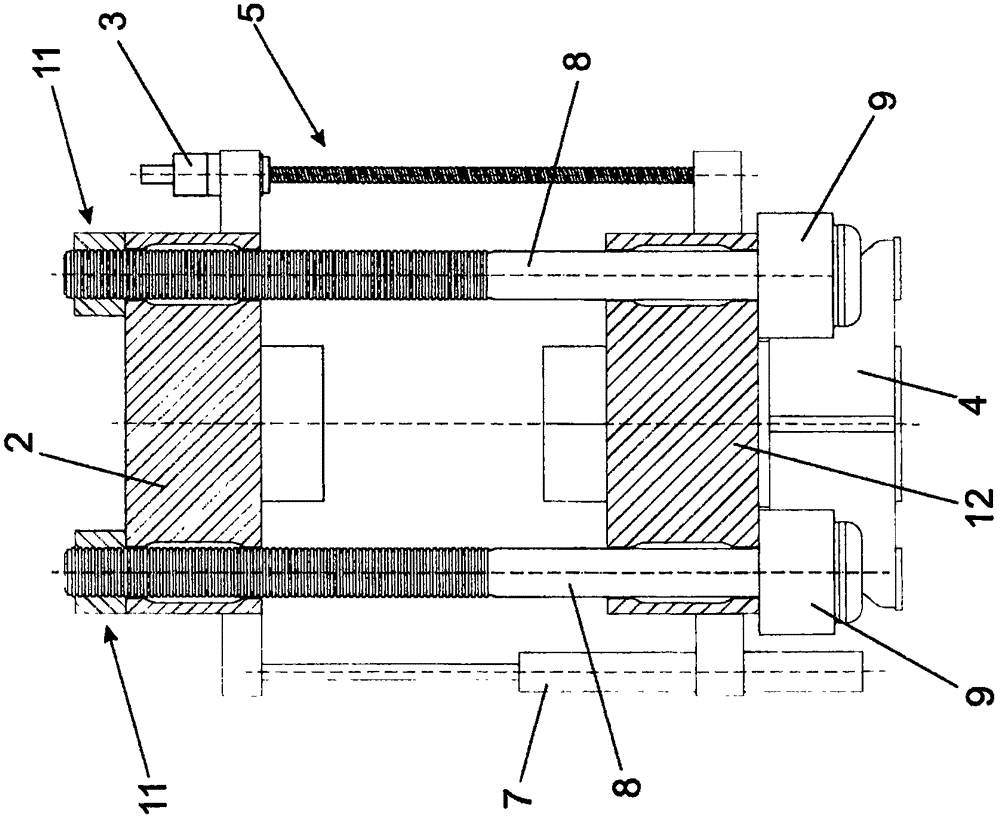

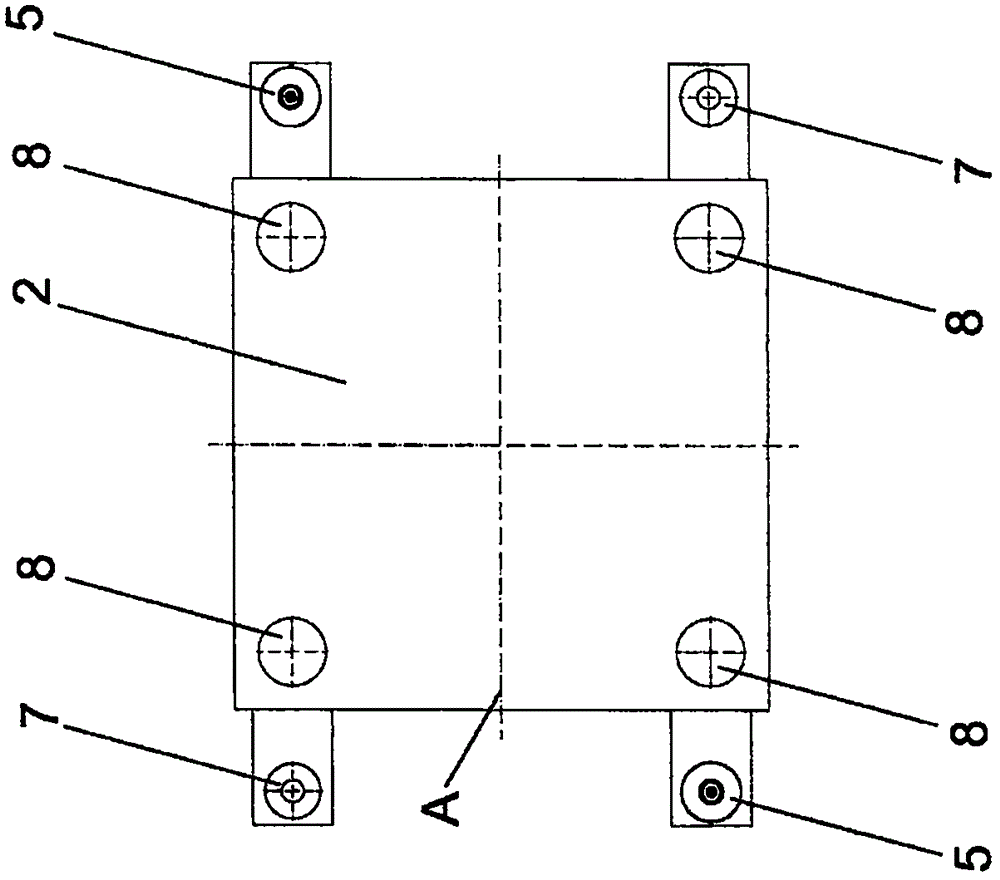

[0029] The closing unit has a movable mold clamping plate 2 and a fixed mold clamping plate 12 assembled on the base 4. The four beams 8 are guided through the movable mold clamping plate 2 and the fixed mold clamping plate 12 (this is done by means of the through holes provided in the movable mold clamping plate 2 and the fixed mold clamping plate 12 Bushing realization). The movable mold clamping plate 2 can be locked relative to the beam 8 by means of a locking device 11. This is achieved by means of a split nut with an inner profile. If the nut is closed, the inner contour engages the outer contour of the beam 8, thereby forming a form fit. The pressure pad 9 is assembled on the side of the fixed mold clamping plate 12 away from the movable mold clamping plate 2. The pressure pad is constructed hydraulically. Its piston part is configured to be connected to the beam 8 or formed by these beams. By making th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com