Water purifier capable of being produced flexibly

A water purifier, a flexible technology, applied in the field of purifiers, can solve the problems of high R&D and mold costs, longer payback cycle, long R&D and production cycle, etc., to achieve the effect of reducing product cycle, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention and specific implementation thereof are described in further detail below in conjunction with accompanying drawing:

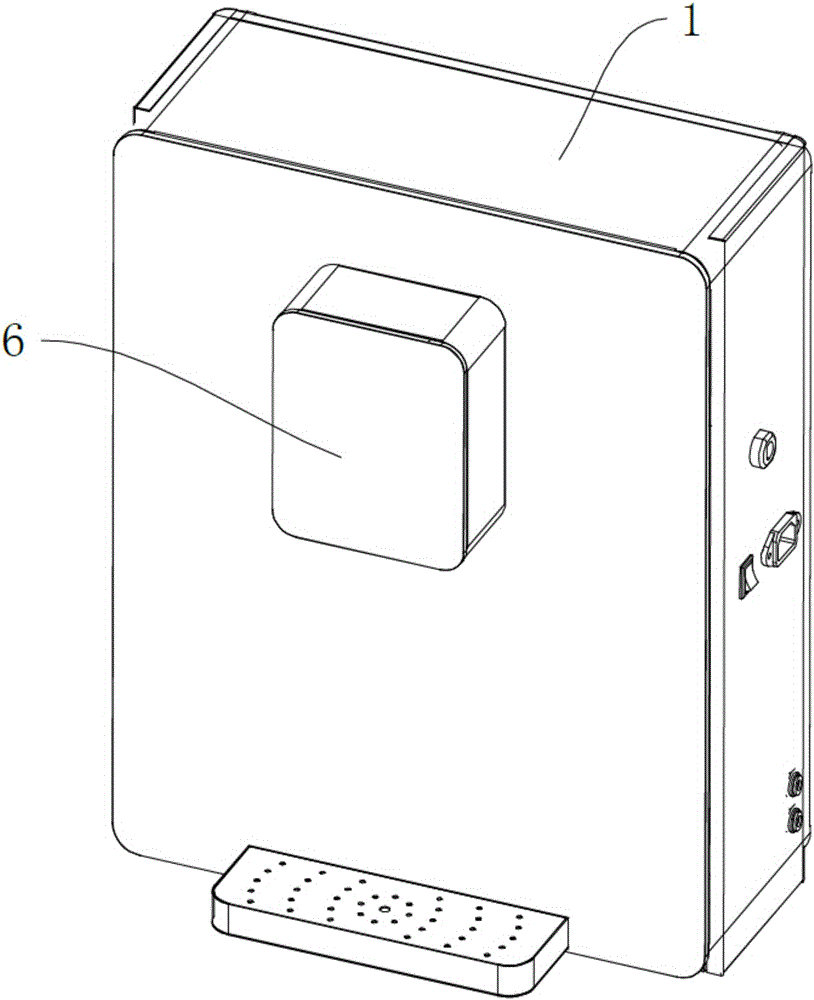

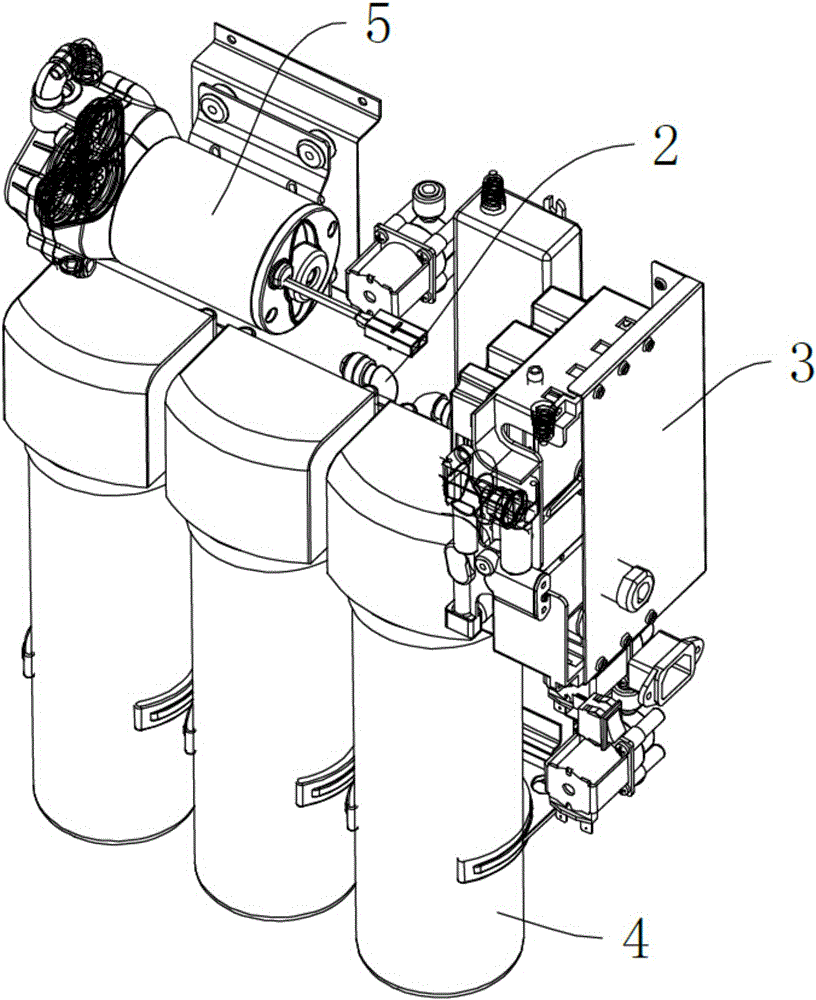

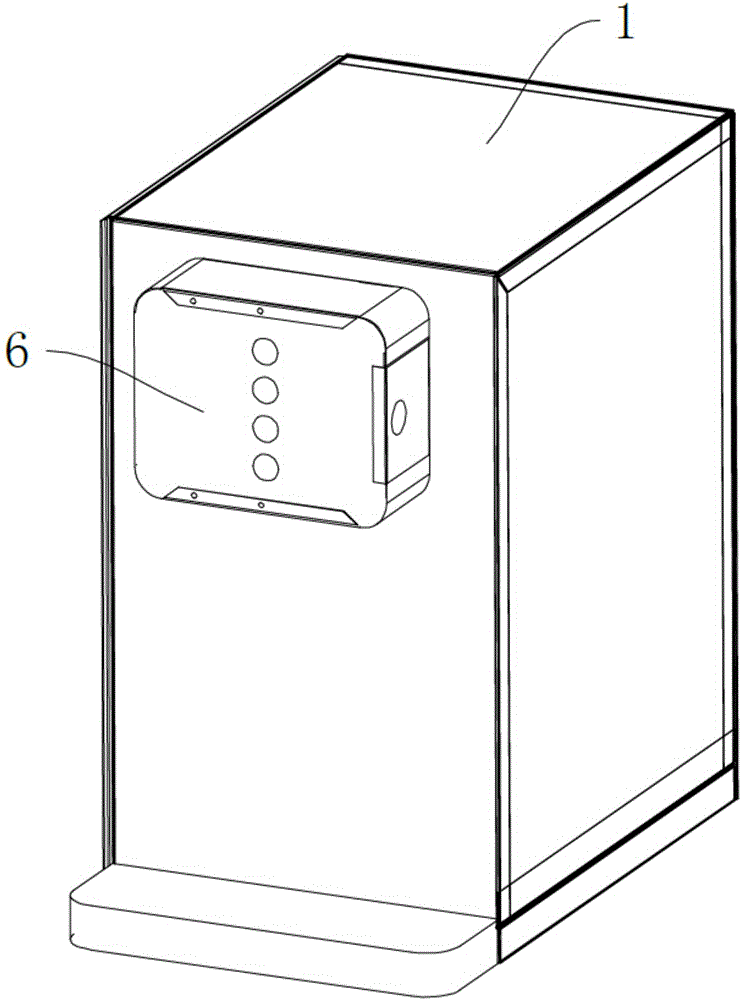

[0023] see Figure 1 to Figure 4 , the present invention includes a casing 1, a waterway 2, a circuit, a valve body 3, a filter element 4, a water pump 5, and a control display module 6, and is characterized in that: the structure of the casing 1 adopts a sheet metal splicing method, and the control display module 6 Located on the outside of the casing 1, this process does not require mold opening to manufacture water purifiers, and the casing can be quickly customized according to needs to achieve flexible production, and the hardware upgrade of the purifier is not limited, such as increasing the flow rate, adding additional functions such as cooling and heating , reduce R&D costs, mold opening costs and apportionment of product mold costs, shorten the R&D cycle, reduce mold manufacturing costs, and make the products more diverse, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com