Electroplating device stably clamping PCBs

A technology for PCB boards and electroplating devices, applied in the field of electroplating devices that firmly clamp PCB boards, can solve problems such as easy drop to the tank body of electroplating quality, difficulty in mixing the electroplating solution, and irrelevant PCB board clamping, etc., to achieve enhanced Efficiency, reduction of dead angle, effect of reducing dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

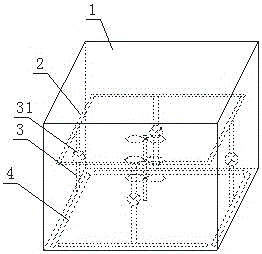

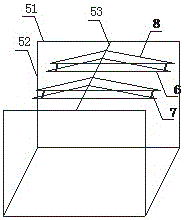

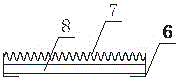

[0034] Figure 1 to Figure 3 An electroplating device 1 for stably clamping a PCB board provided by the present invention includes a tank body 1 and a PCB board clamping device, wherein,

[0035] The bottom of tank body 1 is provided with liquid spray pipe 4 around, and the upper part of tank body 1 is provided with liquid suction pipe 2 close to the side wall. The liquid suction pipe 2 is connected, the outlet of the water pump 3 is connected with the liquid spray pipe 4, and the surfaces of the liquid suction pipe 2 and the liquid spray pipe 4 are all provided with round holes 43;

[0036] The liquid spray pipe 4 includes a connecting part 41 and a rotating part 42, the middle part of the connecting part 41 is fixedly connected to the outlet of the water pump 3, and the two ends of the connecting part 41 are respectively connected to the rotating part 42 in rotation;

[0037] The lower part of the tank body 1 is provided with stirring paddles, and the rotating shafts of the...

Embodiment 2

[0042] Figure 1 to Figure 3 An electroplating device 1 for firmly clamping a PCB board provided by the present invention includes a tank body 1 and a PCB board clamping device, wherein,

[0043] The bottom of tank body 1 is provided with liquid spray pipe 4 around, and the upper part of tank body 1 is provided with liquid suction pipe 2 close to the side wall. The liquid suction pipe 2 is connected, the outlet of the water pump 3 is connected with the liquid spray pipe 4, and the surfaces of the liquid suction pipe 2 and the liquid spray pipe 4 are all provided with round holes 43;

[0044] The liquid spray pipe 4 includes a connecting part 41 and a rotating part 42, the middle part of the connecting part 41 is fixedly connected to the outlet of the water pump 3, and the two ends of the connecting part 41 are respectively connected to the rotating part 42 in rotation;

[0045] The lower part of the tank body 1 is provided with stirring paddles, and the rotating shafts of the...

Embodiment 3

[0052] Figure 1 to Figure 3 An electroplating device 1 for stably clamping a PCB board provided by the present invention includes a tank body 1 and a PCB board clamping device, wherein,

[0053] The bottom of tank body 1 is provided with liquid spray pipe 4 around, and the upper part of tank body 1 is provided with liquid suction pipe 2 close to the side wall. The liquid suction pipe 2 is connected, the outlet of the water pump 3 is connected with the liquid spray pipe 4, and the surfaces of the liquid suction pipe 2 and the liquid spray pipe 4 are all provided with round holes 43;

[0054] The liquid spray pipe 4 includes a connecting part 41 and a rotating part 42, the middle part of the connecting part 41 is fixedly connected to the outlet of the water pump 3, and the two ends of the connecting part 41 are respectively connected to the rotating part 42 in rotation;

[0055] The lower part of the tank body 1 is provided with stirring paddles, and the rotating shafts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com