Segmented Double Press Needle Knitting System of Computerized Jacquard Circular Knitting Machine

A technology for jacquard knitting needles and knitting systems, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of affecting the cloth surface effect, increasing the machine load, and knitting needle wear, etc., to expand product development methods, reduce Machine load, reduced needle wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

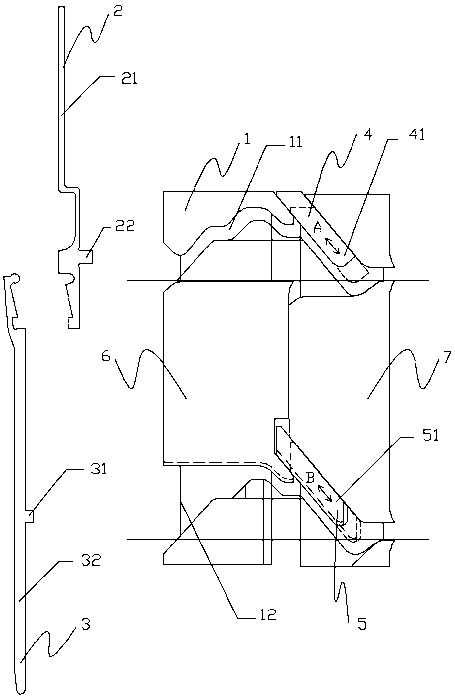

[0020] Such as image 3 As shown, the segmented double-press needle knitting system of the computer jacquard circular knitting machine of the present invention is provided with a main body 1, and the upper and lower ends of the main body 1 are respectively provided with knitting needle guide grooves 11 and The middle needle guide groove 12 for cooperating with the movement of the middle needle 3, the first telescopic device 4 for controlling the depth of the knitting needle pressing needle is installed at the said knitting needle guide groove 11, and the said middle needle guide groove 12 is installed with a device for controlling the middle The second telescoping device 5 for needle pressing depth.

[0021] The first telescoping device 4 includes a first driving device and a first pressing needle 41 that is transmission-connected with the first driving device, and the first pressing needle 41 is installed at the knitting needle guide groove 11 provided on the main body 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com