Air inlet valve and air compressor applying same

An intake valve and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as loss, solenoid valve damage energy, and reduced intake efficiency, so as to achieve no damage and reduce intake. The effect of high air resistance and air intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

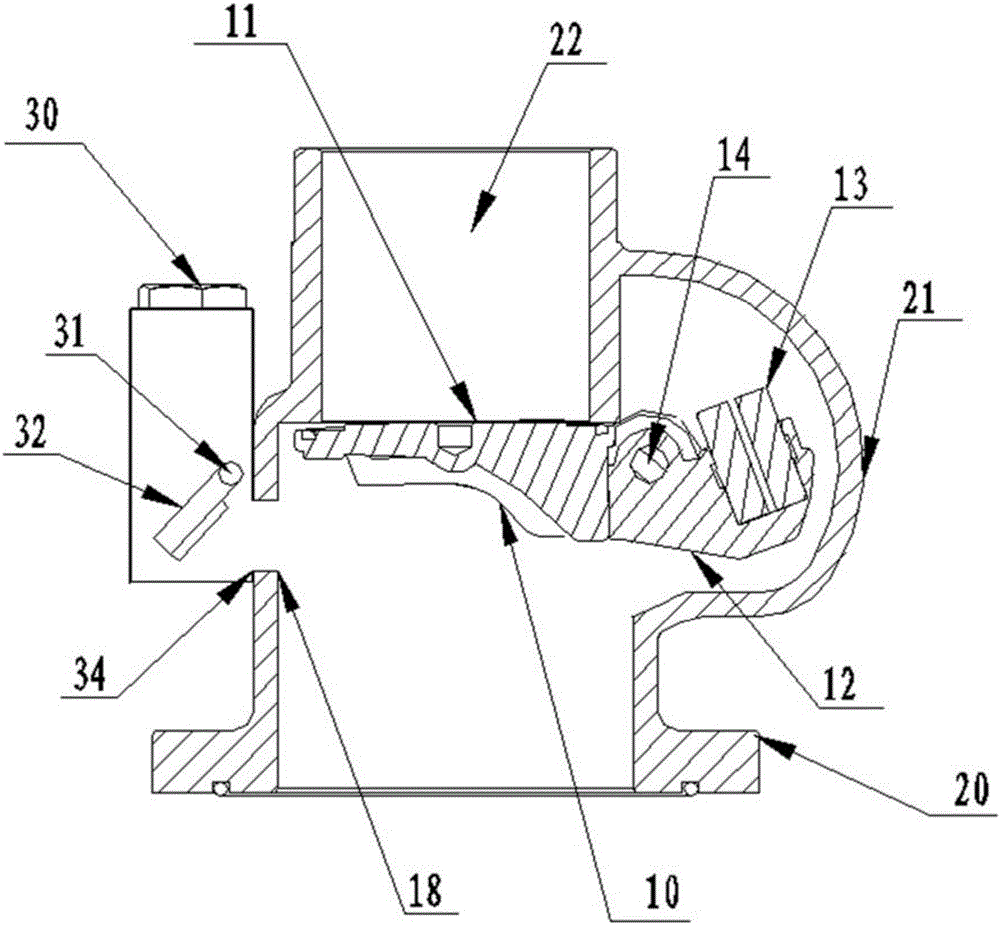

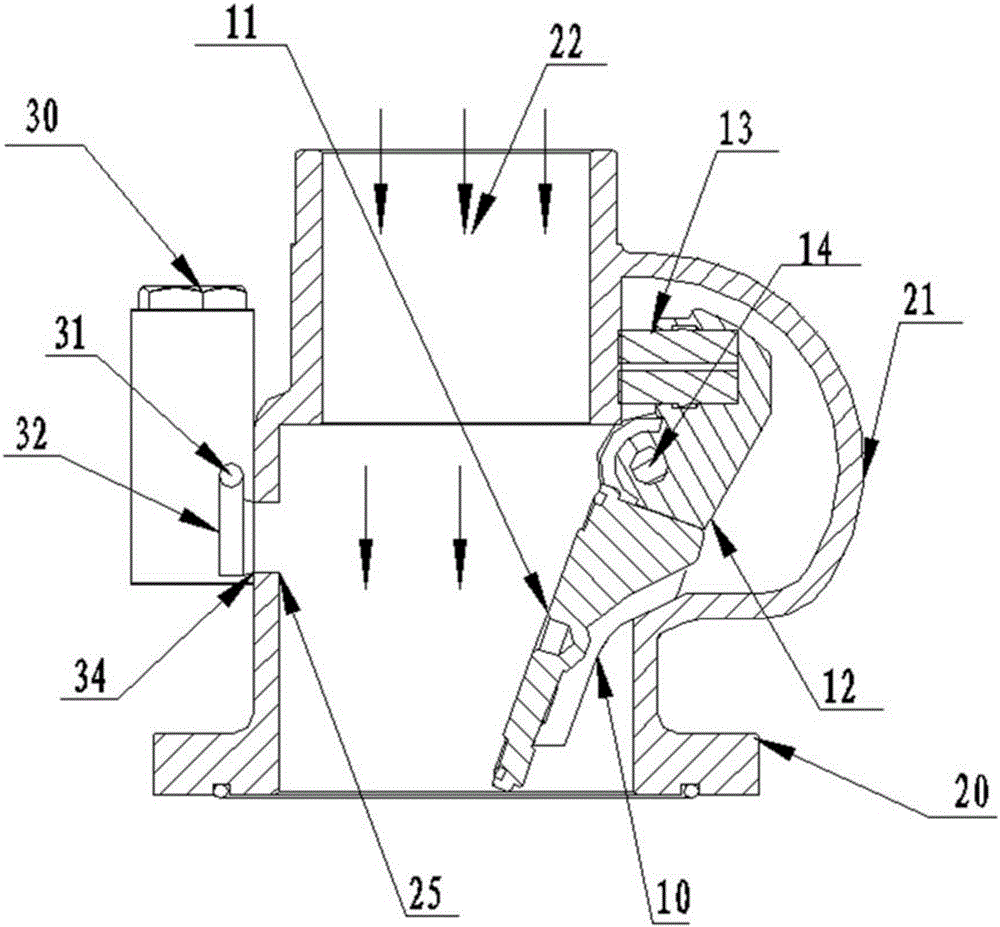

[0045] In a first embodiment of the invention, an intake valve is provided. Such as Figure 1~4 As shown, the air compressor of this embodiment includes a motor, a compressor host, an intake valve, a frequency converter, and a controller.

[0046] The intake valve includes: a check cover 10 , a valve body 20 , and a vent valve 30 .

[0047] The inside of the valve body 20 forms a first chamber, a valve body inlet 22 is formed above the first chamber, and a valve body pressure relief port 25 is formed on the side of the chamber. The valve body wall on the side where the first bolt 14 is located protrudes outwards to form a protruding chamber 21 . Wherein, the protruding chamber 21 provides space for the gravity block 13 fixed on the second end of the lever 12 to swing up and down.

[0048] The non-return cover includes: a cover body 11 , a lever 12 and a gravity block 13 . A first round hole 15 is opened on the lever 12, and the first bolt 14 passes through the first round ...

no. 3 example

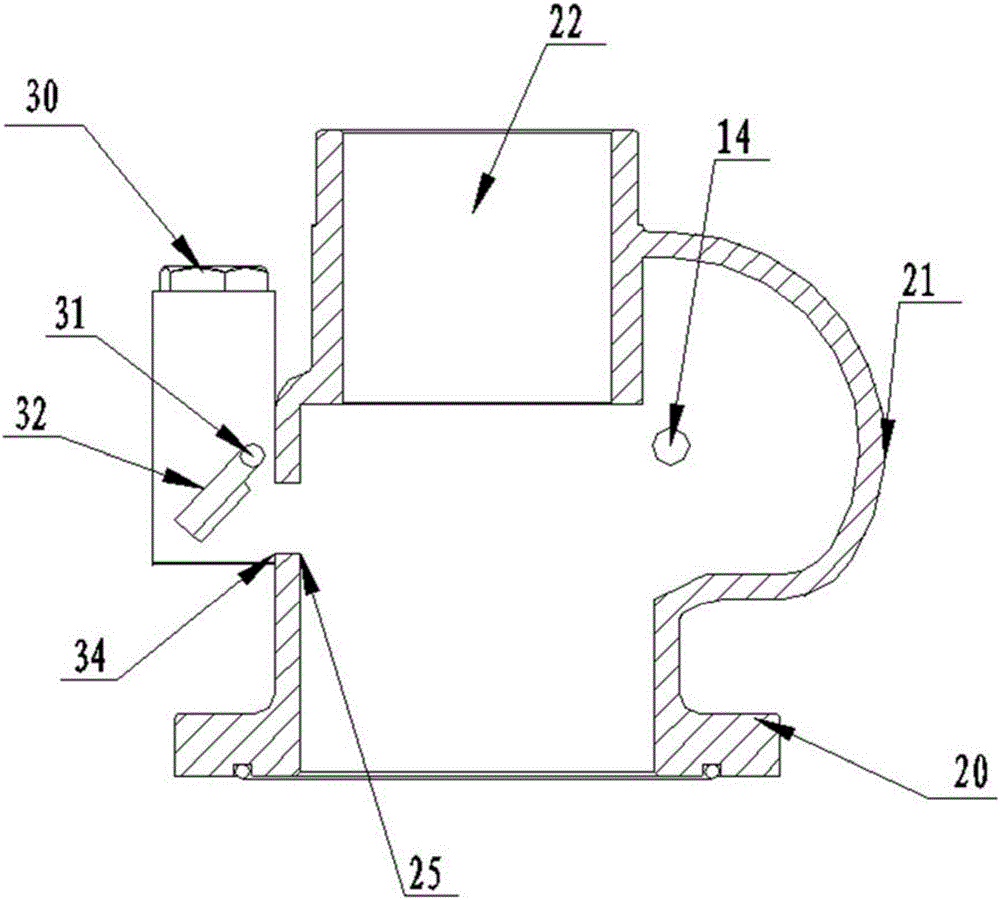

[0056] In a first embodiment of the present invention, another intake valve is provided. The compressor of this embodiment is similar to the air compressor of the first embodiment, the only difference is that the present invention adopts tension spring tension to replace the self-weight effect of the non-return cover 10 and the isolating device 32 .

[0057] Specifically, as Figure 5-8 As shown, the intake valve in this embodiment includes: a check cover 10 , a valve body 20 , and a vent valve 30 .

[0058] The non-return cover (10) includes: a cover body 11, a first tension spring 17, and a first bolt 14. The cover body 11 is sheet-shaped, and has a third round hole 16 at one end. The first bolt 14 passes through the third round hole 16 and is fixed on the inner wall of the valve body 20 , which can completely fasten the air inlet 22 of the valve body. One end of the first extension spring 17 is fixed on the side of the cover body 11 close to the air inlet 22 of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com