A valve for hopper car unloading

A technology of functioning valves and hopper cars, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problem that the hopper car cannot realize the simultaneous unloading of multiple connected vehicles, and achieve high practicability and economy, and a stable closing state And reliable, improve the sealing reliability and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

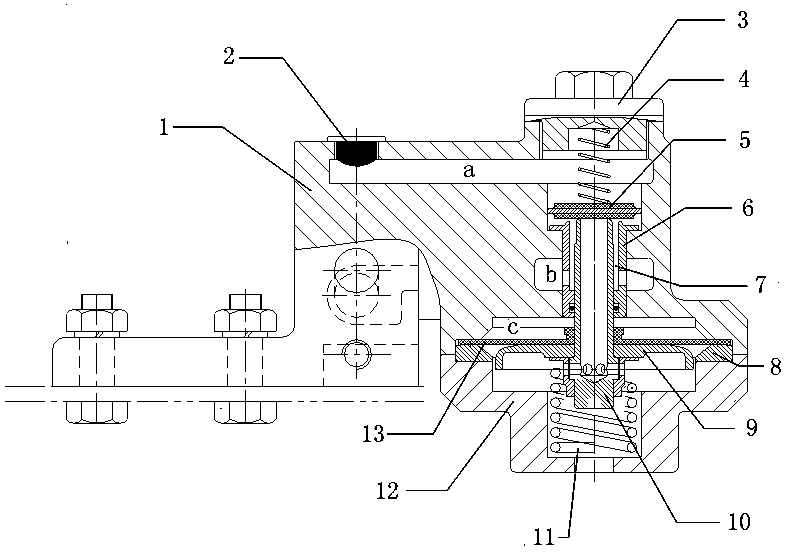

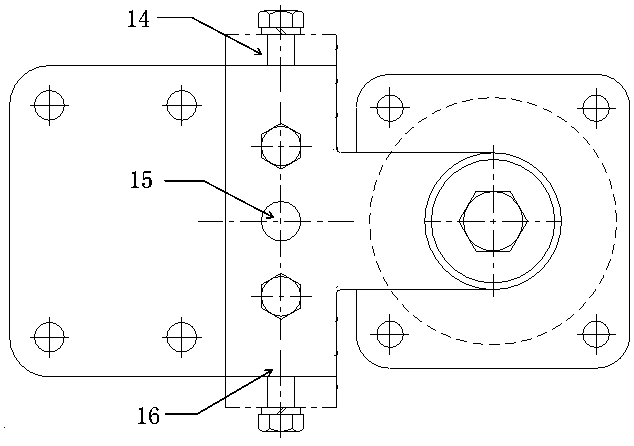

[0020] Such as figure 1 , 2 As shown, a valve used for unloading a funnel car includes a valve body 1, a lower body 12, a valve cover 3, a compression spring 14, a sandwich valve 5, a valve seat 6, a valve stem 7, a diaphragm 13, a diaphragm baffle 9, Spring holder 10, compression spring II11 and sealing ring 8, valve body 1 is provided with air storage chamber a, closing air chamber b, control air chamber c and cavity, air storage chamber a is provided with air storage cylinder air inlet 15, closed The air chamber b is provided with a two-way air cylinder air inlet 14, the control air chamber c is provided with a control pipe air inlet 16, the air storage chamber a, the closed air chamber b and the control air chamber c are connected by a cavity, and the upper and lower parts of the cavity are provided with There is an opening, the lower opening of the cavity is sealed by the lower body 12, a sealing ring 8 is provided between the valve body 1 and the lower body 12, a valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com