Welding type sealing device for steam heating discharging of biodiesel raw material liquid bag

A biodiesel, raw material liquid technology, applied in liquid distribution, transportation or transfer devices, distribution devices, special distribution devices, etc., can solve the problems of pollution, reduce thermal efficiency, reduce work efficiency, etc. The effect of improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The steam heating discharge welding sealing device of the biodiesel raw material liquid bag of the present invention will be further described in detail below in combination with specific implementation methods.

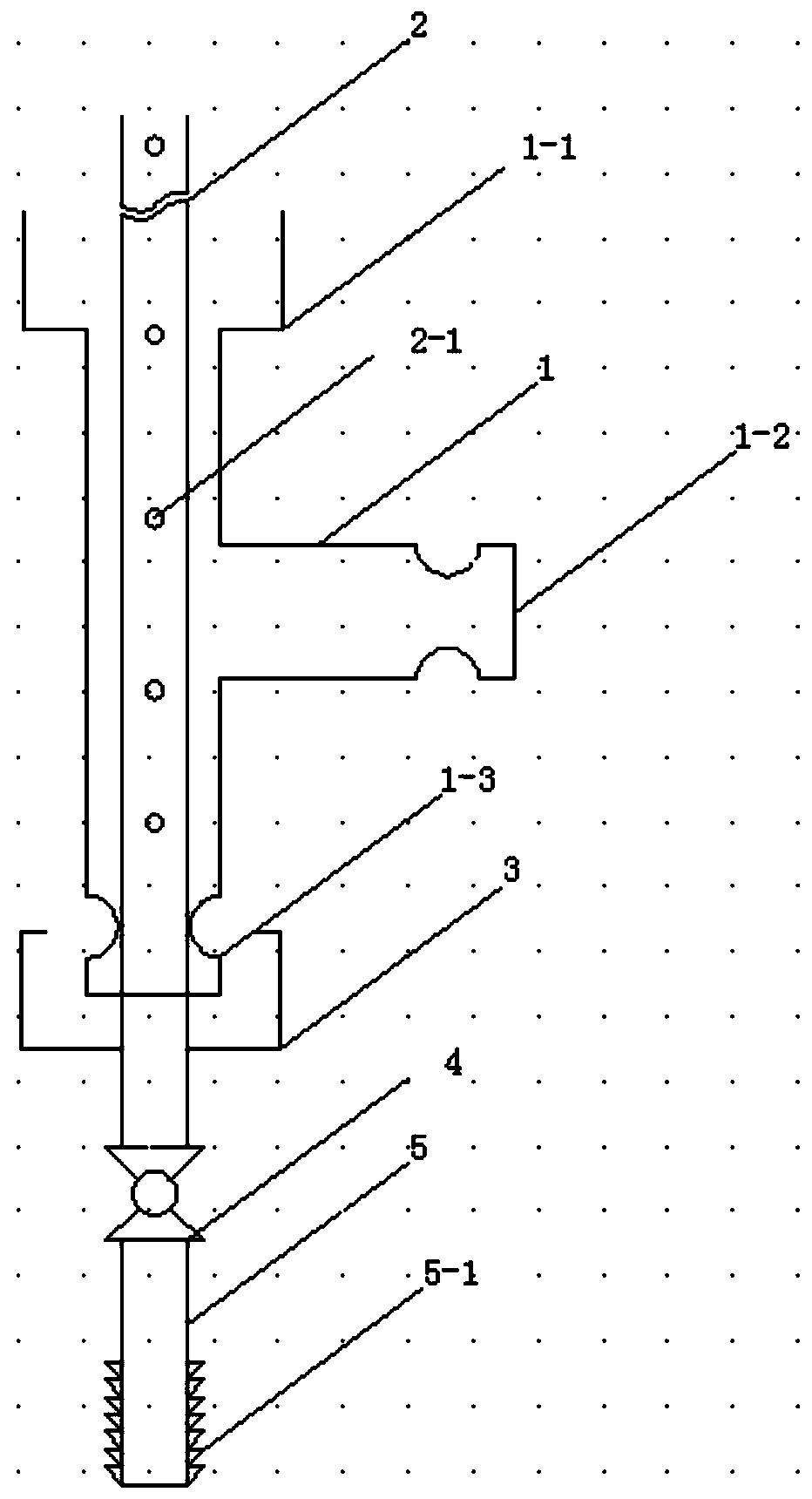

[0014] figure 1 As shown, the biodiesel raw material liquid bag steam heating discharge welding type airtight device of the present invention includes a tee 1, a stainless steel perforated steam pipe 2 with a plurality of evenly distributed steam holes 2-1, a female end quick connector cover 3, a quick open The valve 4 and the stainless steel steam pipe 5 with a flat top pagoda head 5-1 at the end; the quick opening valve 4 is connected between one end of the stainless steel steam pipe 5 and the lower end of the stainless steel perforated steam pipe 2, and the other end passes through a flat The top pagoda head 5-1 is connected to the steam leather pipe; the straight-through pipe of the tee 1 is sleeved on the stainless steel perforated steam pipe 2, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com