Heat management module and rotation valve thereof

A rotary valve and heat management technology, applied in multi-way valves, valve devices, valve details, etc., can solve problems such as sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The thermal management module of the present invention will be described in detail below with reference to the accompanying drawings.

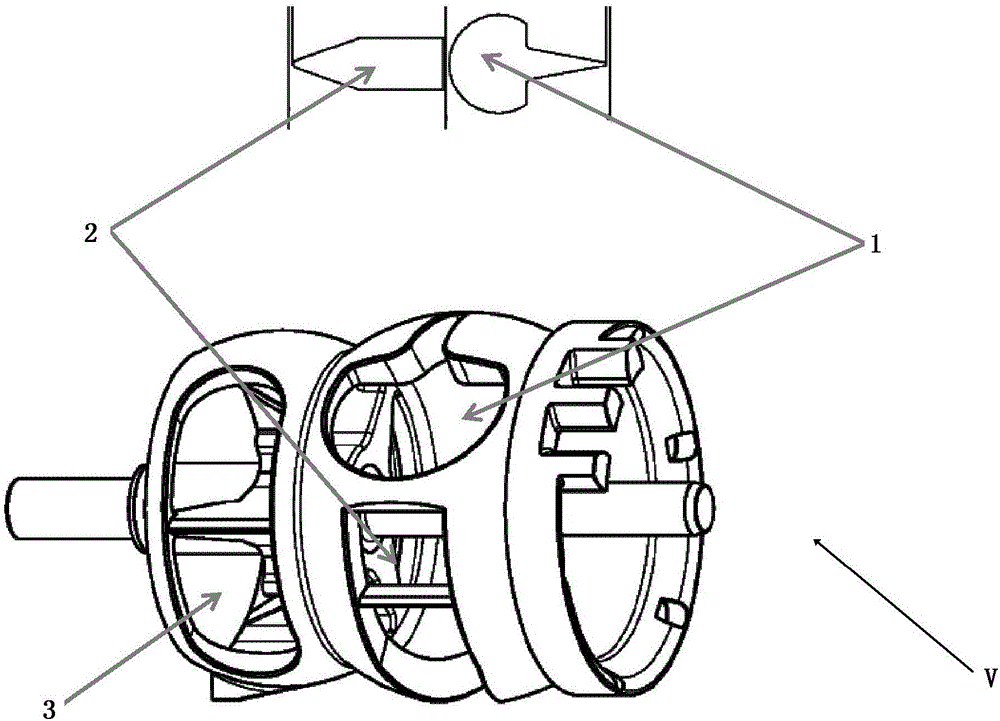

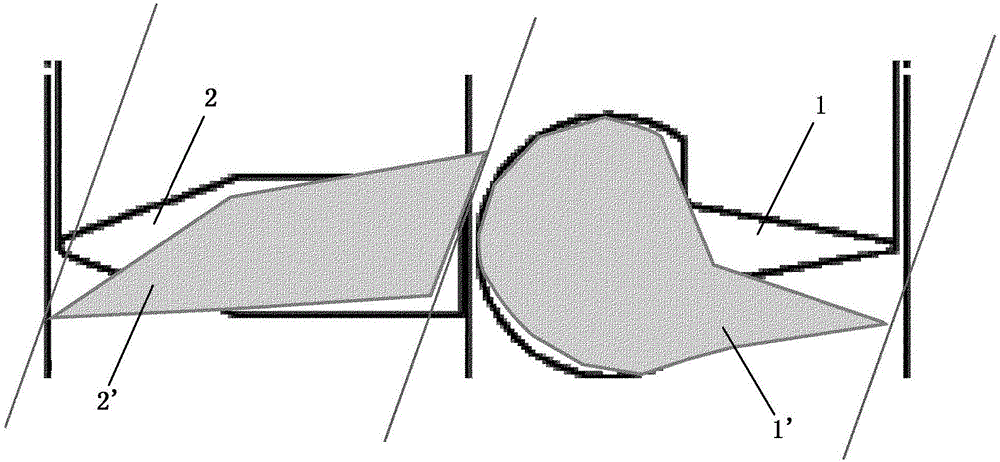

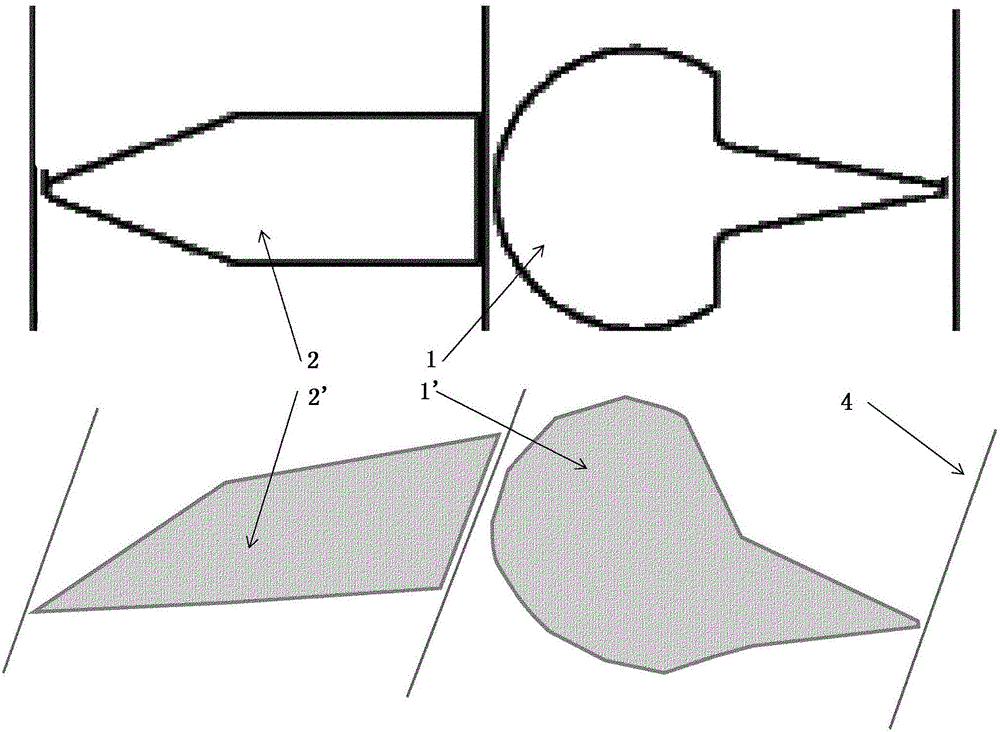

[0027] figure 1 A perspective view showing a rotary valve of a thermal management module of the prior art. Such as figure 1 As shown, the rotary valve V of the thermal management module in the prior art has multiple channels, for example, three channels. The channel has openings such as opening 1 , opening 2 and opening 3 . Each of opening 1 , opening 2 and opening 3 is symmetrical with respect to the corresponding cross-section of rotary valve V . In other words, each of the opening 1 , the opening 2 and the opening 3 is bilaterally symmetrical in the axial direction of the rotary valve V. As shown in FIG. The opening 1 and the opening 2 are arranged successively in the circumferential direction of the rotary valve, and the opening 3 is arranged on one side of the opening 1 and the opening 2 in the axial direction of the rotary val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com