Heating stove with fast ash falling function

A heating stove and ash-falling technology, which is applied to household stoves/stoves, stoves/stoves with hot water devices, and household heating, etc., can solve problems such as energy waste, environmental impact, and small heat transfer area, and avoid The effect of waste, avoiding blockage and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

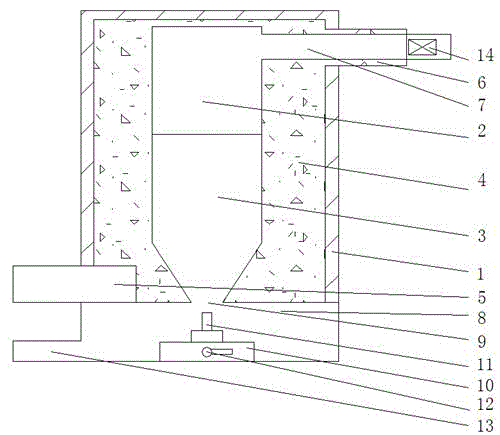

[0016] Such as figure 1 As shown, a kind of fast falling ash heating furnace of the present invention comprises a furnace body 1, and the upper part of the furnace chamber 2 and the lower combustion chamber 3 are formed in the furnace body 1, and the furnace body 1 forms with the furnace chamber 2 and the combustion chamber 3 The cavity is a water chamber 4, the bottom of the furnace body 1 is connected with a water inlet pipe 5, the upper part of the furnace body 1 is connected with a water outlet pipe 6, and the outlet pipe 6 is also provided with a smoke outlet pipe 7 connected to the furnace chamber 2, and the combustion chamber 3 The bottom is connected with a furnace bottom 8, the bottom of the combustion chamber 3 is funnel-shaped, and an ash discharge device is arranged inside the furnace bottom 8, and the ash discharge device is facing the outlet 9 of the funnel-shaped combustion chamber 3. The ash-discharging device comprises a base 10 installed in the furnace bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com