Semiconductor or light energy heating blow-molding water tank electric water heater having water flow sensor

A technology of water flow sensor and electric water heater, which is applied in fluid heaters, water heaters, lighting and heating equipment, etc. It can solve problems such as water leakage, pressure explosion, and inability to automatically adjust the pressure of water tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

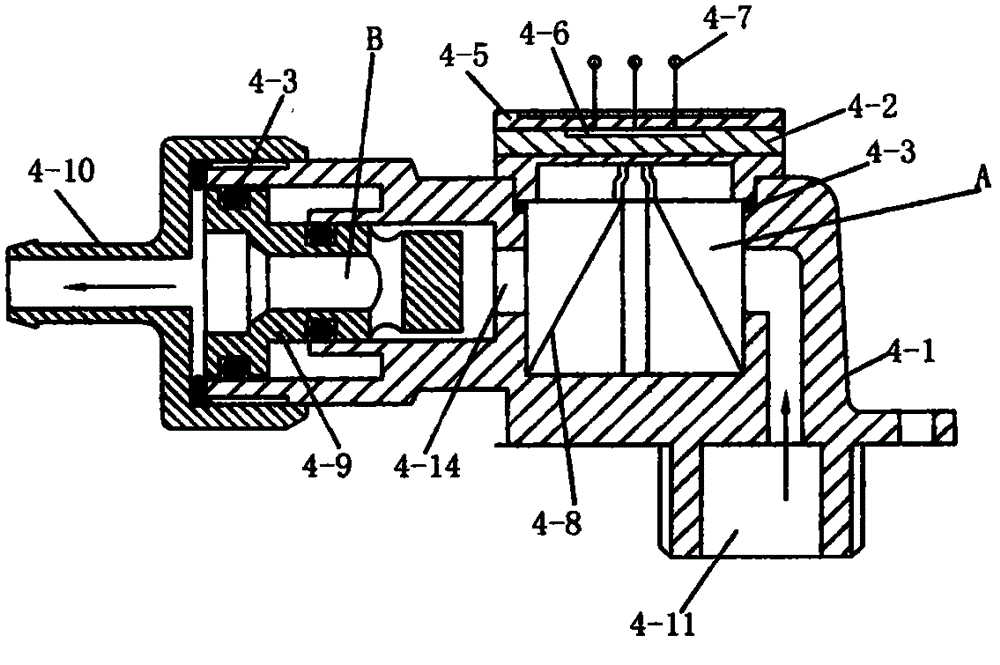

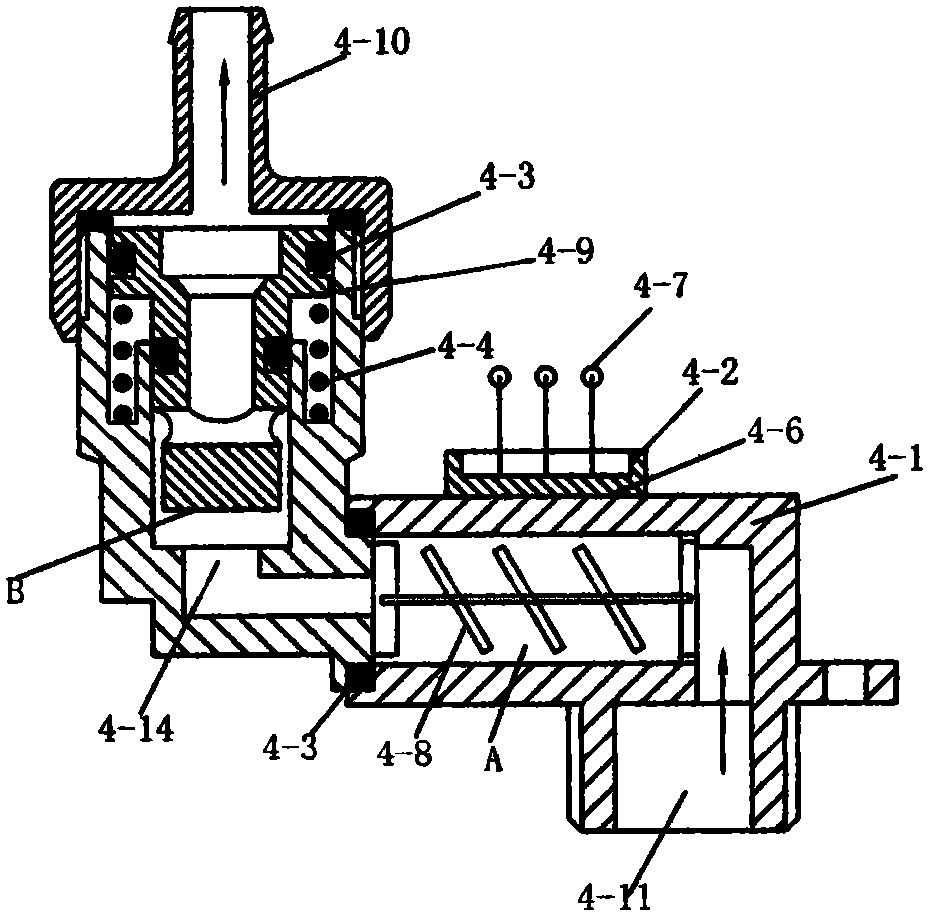

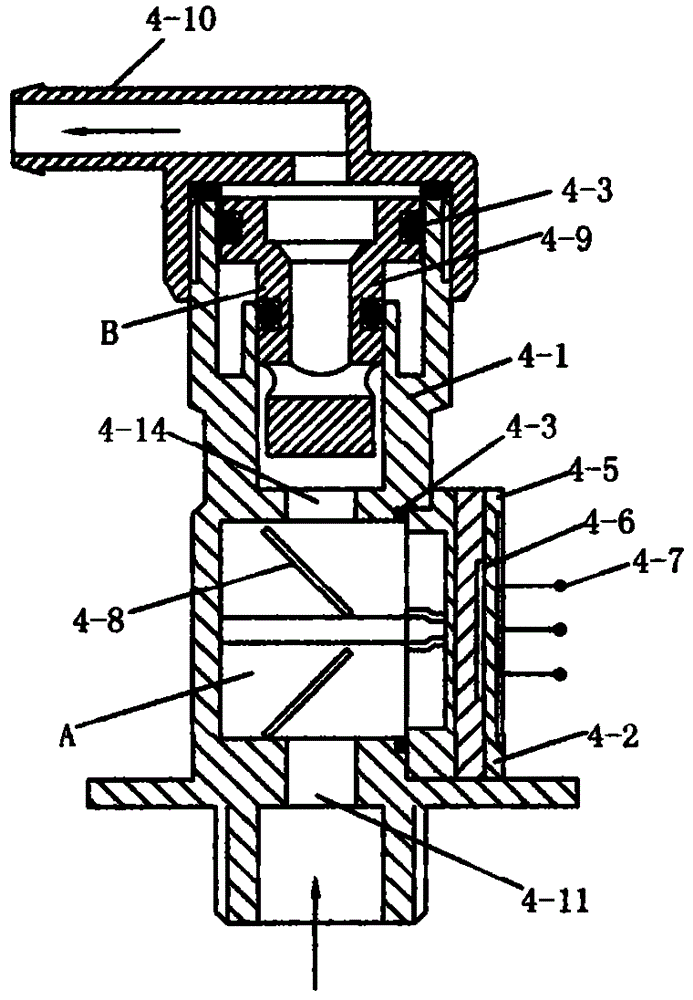

[0014] Attached below Figures 1 to 8 In the accompanying drawings: housing 1, cold water inlet pipe 2, hot water outlet pipe 3, water flow sensor 4 with decompression function, controller 5, electric heating tube 6 (semiconductor or photoelectric heating tube 6- 1. Metal electric heating tube 6-2), sealing and fixing point 7, water tank 8, faucet 9, temperature measuring or temperature limiting sensor installation pipe 10, flange 11, pressure relief valve 14, sewage outlet 15, water flowing through the heating water Device 16, metal or non-metallic casing 17, water 19.

[0015] Figure 1 to Figure 3 There is a water flow sensor 4, which consists of a main body 4-1, a cover plate 4-2, a seal 4-3, a spring 4-4, an installation cover plate 4-5, an inductive element 4-6, a connection terminal 4-7, an impeller or Rotor or Hall element 4-8, piston 4-9, interface 4-10, water inlet 4-11, the water flow sensor is composed of two parts A and B:

[0016] Part A, when there is water fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com