Double-magazine, rifle achieving automatic magazine replacement and submachine gun

A technology for submachine guns and magazines, which can be used in firearms, ammunition supply, weapon accessories, etc., and can solve problems such as inconvenience and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

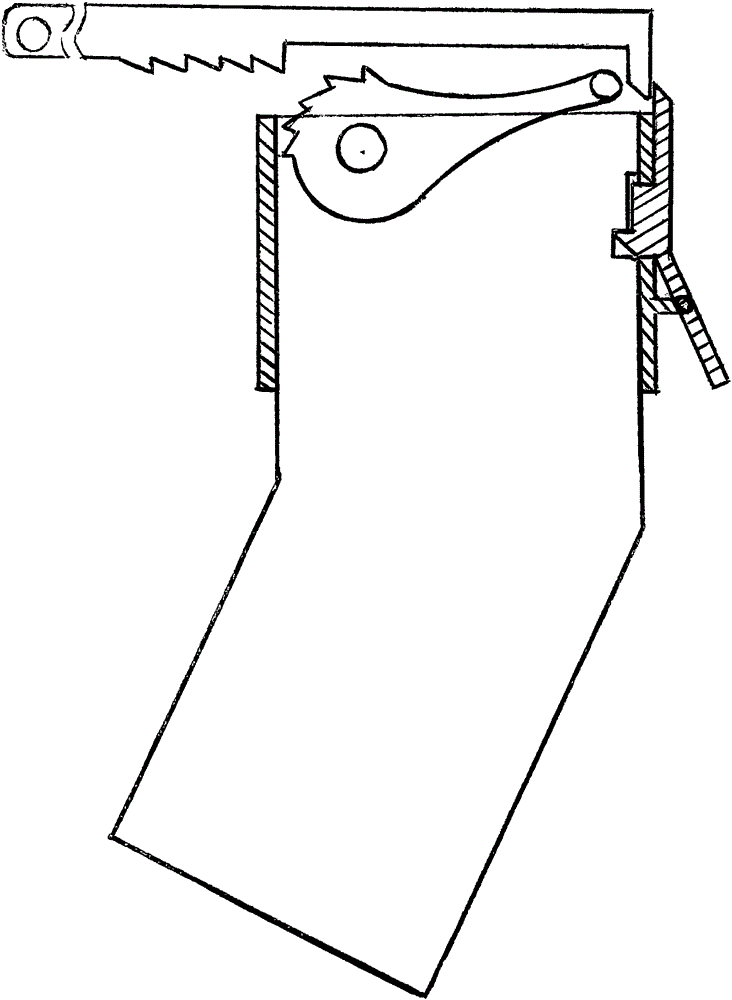

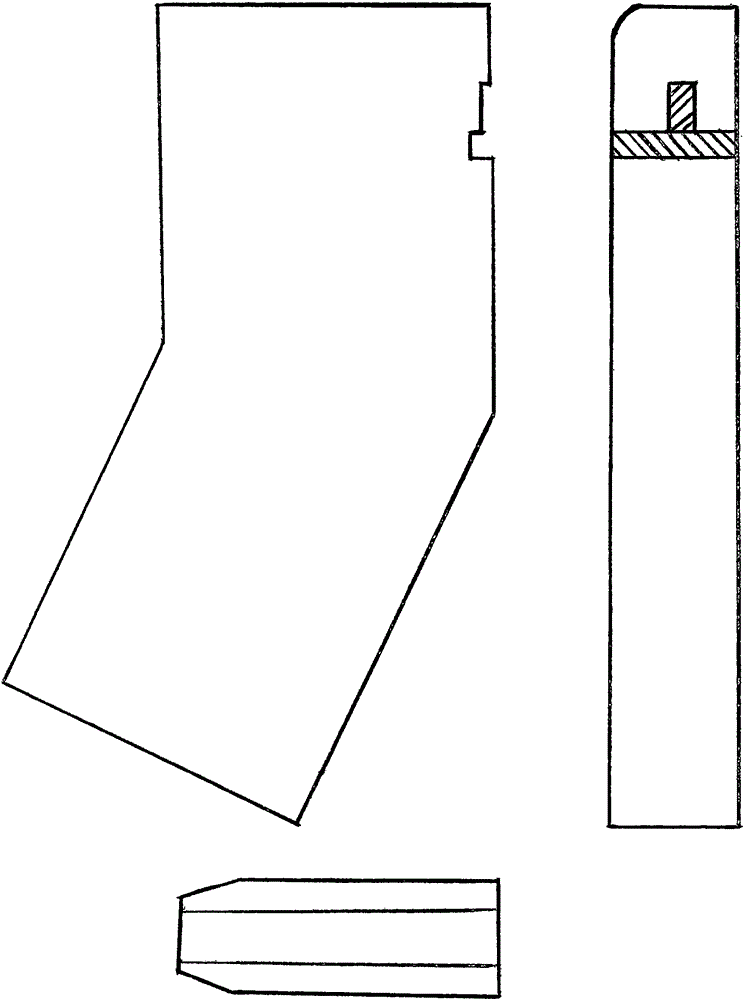

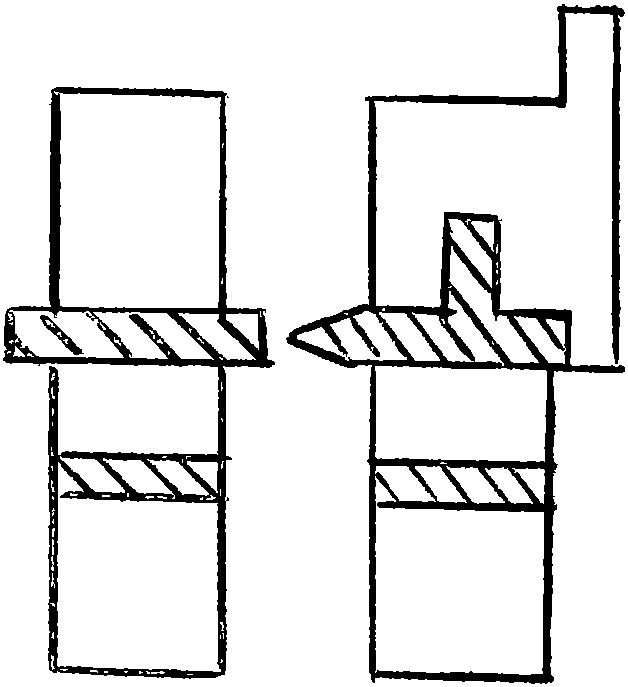

[0015] The structure of the magazine, the magazine chamber, the latch, the metal slide bar, the wheel with the pressure bar, and the slide rail on the gun body are simple, without complicated processes, and there is no difficulty in manufacturing. The magazine is made of metal plate, so that the friction between the magazines and between the magazine and the magazine chamber is small, and the pressing rod can easily press the magazine out of the magazine chamber. For firearms without a magazine chamber, a magazine chamber should be added. The wall thickness on the right side of the magazine chamber is about 5mm, and the movable area of the runner is cut to a depth of about 3mm. A shaft with a radius of about 3mm is left at the center of the runner, and the installation belt is twisted. The runner of the spring, except the uppermost tooth is processed from a piece of metal, the uppermost position of the runner is slightly larger than the tooth hole thickness of about 3 mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com