Analog carrying measurement method for ship during hull section joining process

A measurement method and stage technology, applied in the field of shipbuilding, can solve the problems affecting the accuracy of simulated loading operation data, the accuracy of total station measurement data, and the inability to complete target data measurement, so as to avoid adverse effects and reduce measurement operations , the effect of reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this embodiment, the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature defined as "first" and "second" may explicitly or implicitly include one or more of these features.

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

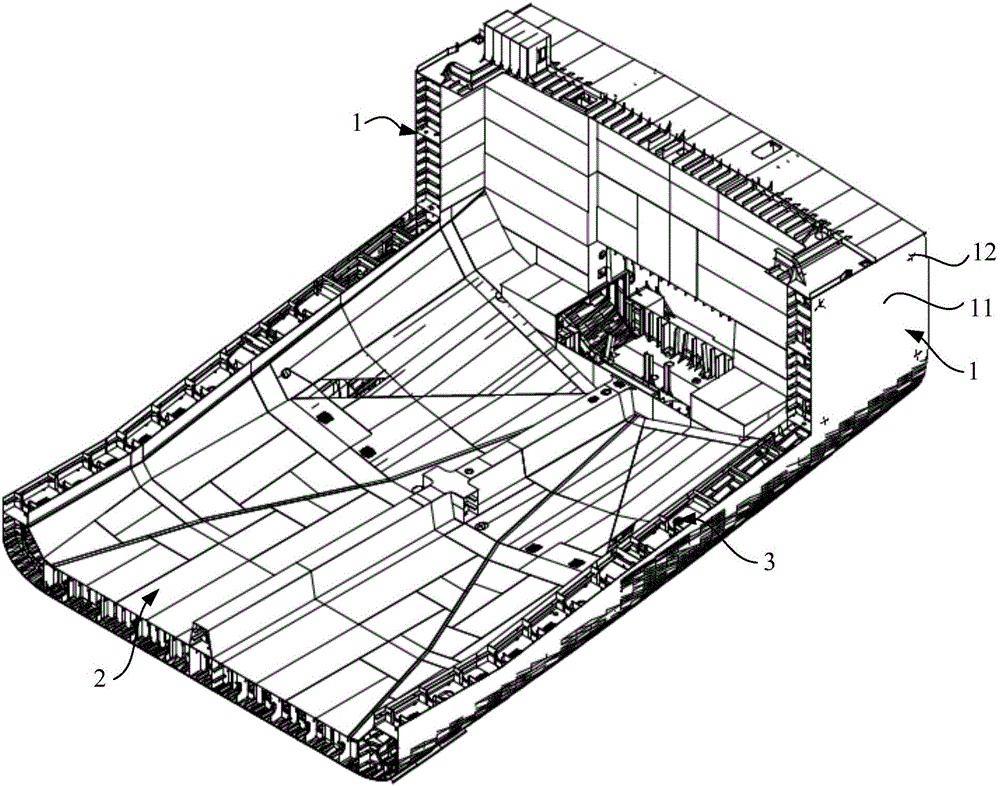

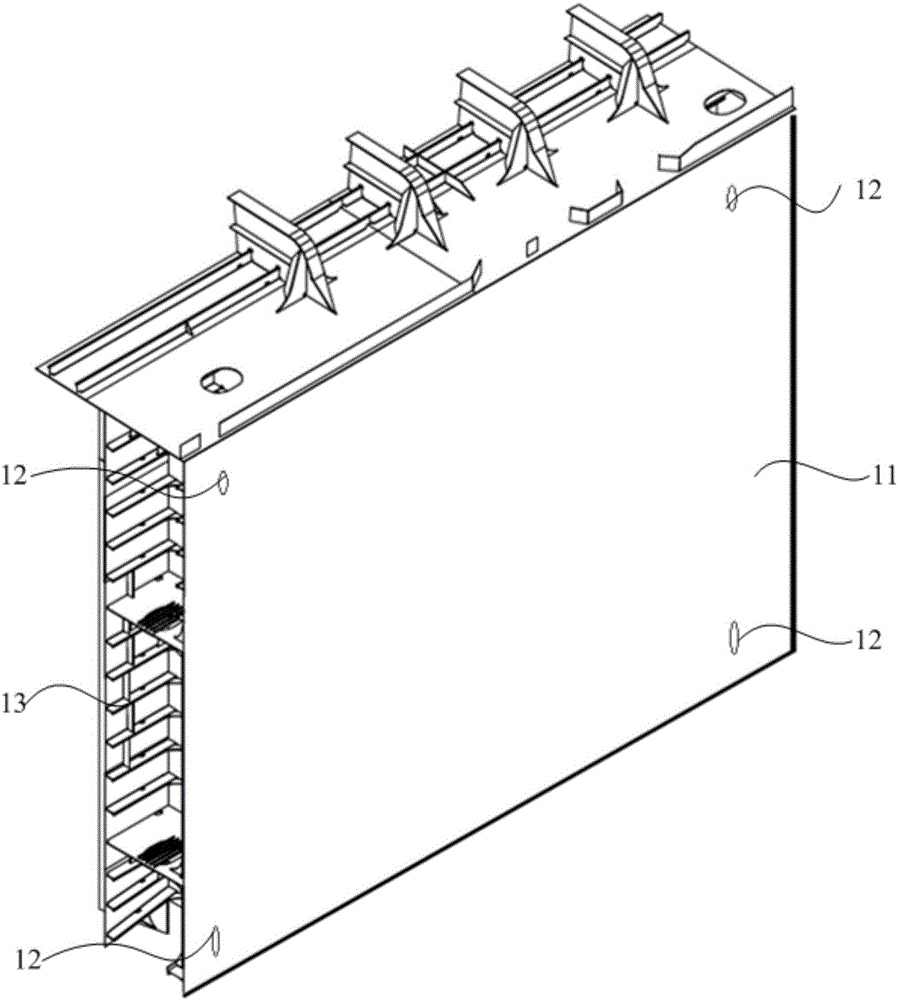

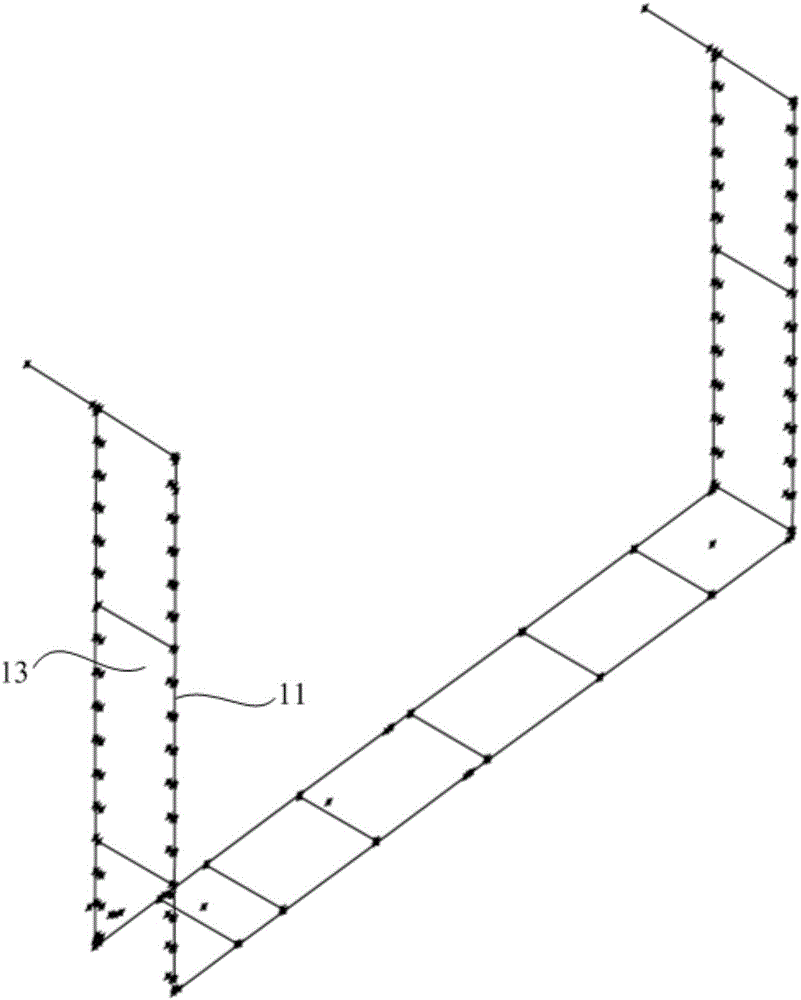

[0035] Such as Figures 1 to 4 As shown, an embodiment of the present invention provides a method for simulating loading of a ship during the large closing stage, comprising the following steps:

[0036] S10, reference point marking, select several reference points 12 at the strong structure position on the side rear section 1, and mark them;

[0037] S20, the first measurement, measuring the profile structure of the rear section 1 of the side, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com