On-site X-ray detection and three-dimensional imaging device of GIS (Gas Insulated Switch)

A three-dimensional imaging and X-ray technology, applied in the field of X-ray detection, can solve problems such as single shooting angle images, achieve good targeted diagnosis, prevent shaking, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

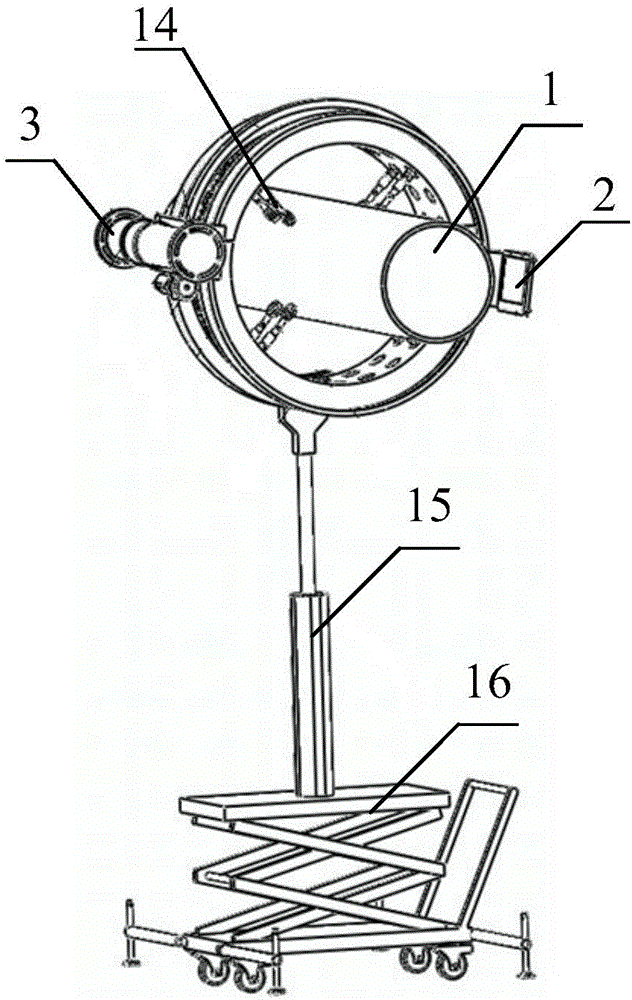

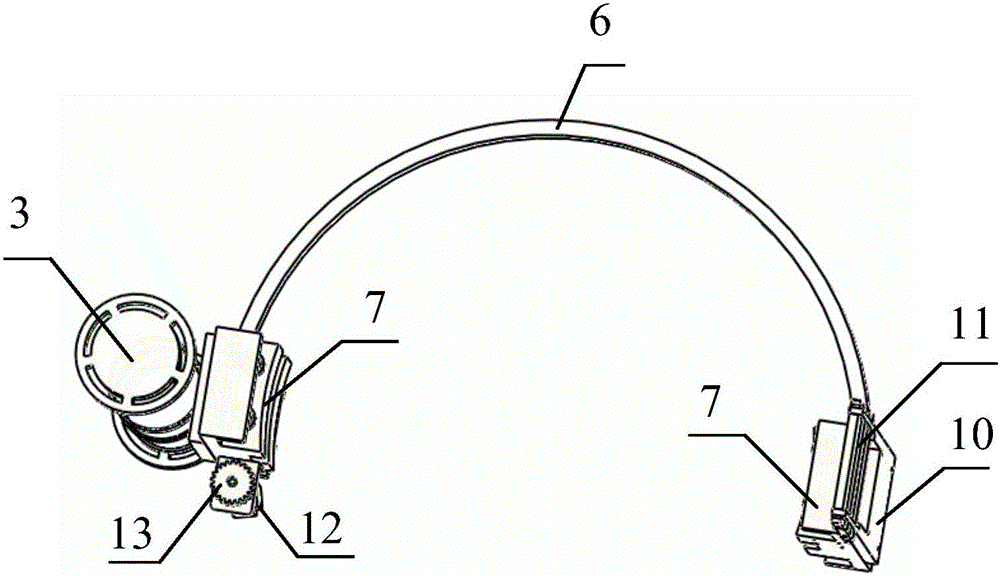

[0024] Such as Figure 1-4 As shown, the present invention discloses a GIS on-site X-ray detection and three-dimensional imaging device, which includes a circular track installed on the GIS outer cylinder 1, a sliding device connected to the circular track and capable of sliding along the circular track, and respectively arranged on the sliding A ray machine 3 and an imaging plate 2 at both ends of the device.

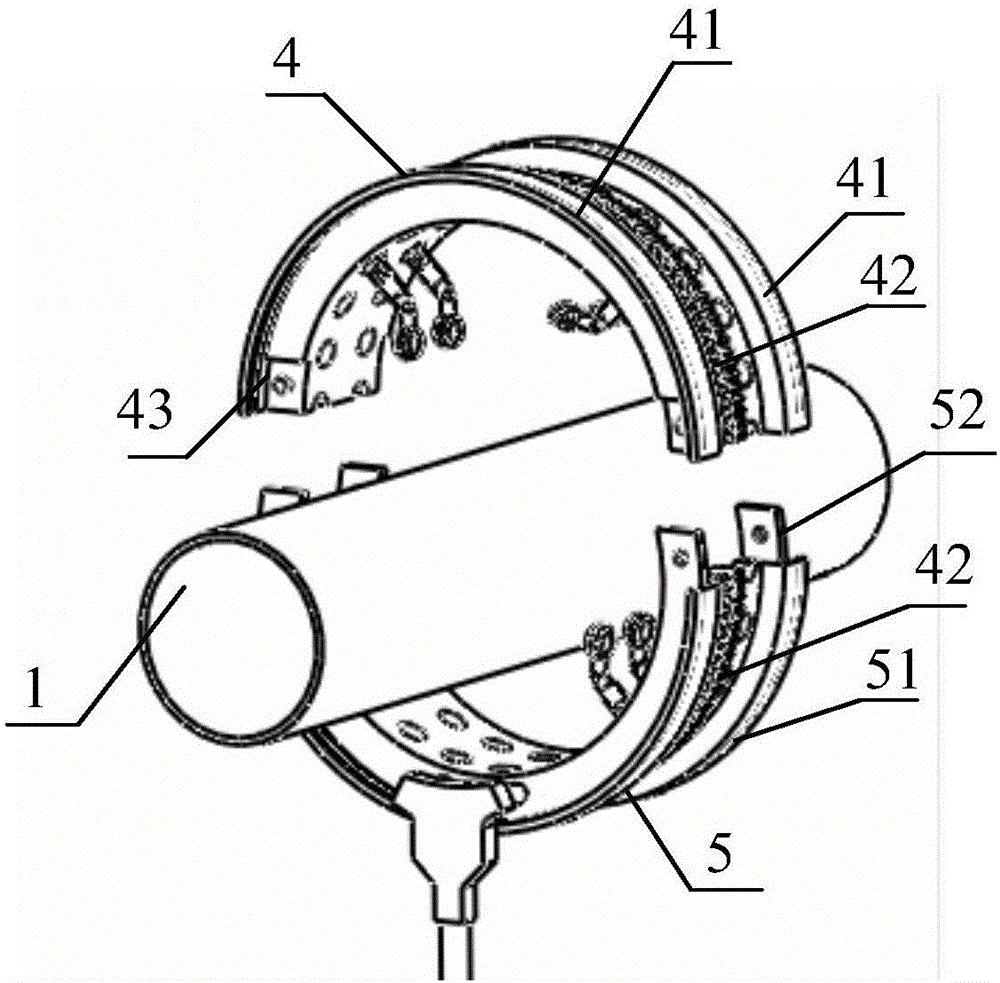

[0025] In order to make the present invention better be installed on the GIS outer cylinder 1, as figure 2 As shown, the circular track includes an upper semicircular track 4 and a lower semicircular track 5 detachably connected to the upper semicircular track 4 . That is, this annular track is made up of detachable upper semicircular track 4 and lower semicircular track 5. When installing, the upper semicircle track 4 and the lower semicircle track 5 are first disassembled, and the GIS outer cylinder 1 is placed between the upper semicircle track 4 and the lower se...

Embodiment 2

[0032] Such as figure 1 As shown, on the basis of the first embodiment, the present invention also includes a support base connected to the side of the lower semicircular track 5 . The upper semicircle track 4 and the inner side of the lower semicircle track 5 are provided with a plurality of universal wheels 14; the universal wheels 14 are symmetrically arranged on the inner side of the upper semicircle track 4 and the lower semicircle track 5, and the quantity can be set as required, in this In the embodiment, the number of universal wheels 14 on the upper semicircular track 4 and the lower semicircular track 5 is respectively set to four.

[0033] Described support base comprises lifting base 16, and the hydraulic rod 15 that is fixed on the lifting base 16, and the end of this hydraulic rod 15 is then connected with the side of lower semicircle track 5 by screw. The height of the supporting base can be adjusted as required, so that the present invention is suitable for di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com