A method for measuring organic selenium content in selenium-enriched peanuts or products prepared therefrom

A technology of selenium-enriched peanuts and organic selenium, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of processing selenium loss, affecting the content of organic selenium, and the inability to quantify selenium compounds, so as to achieve good loss, extraction and reduction of selenium form The effect of changing and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

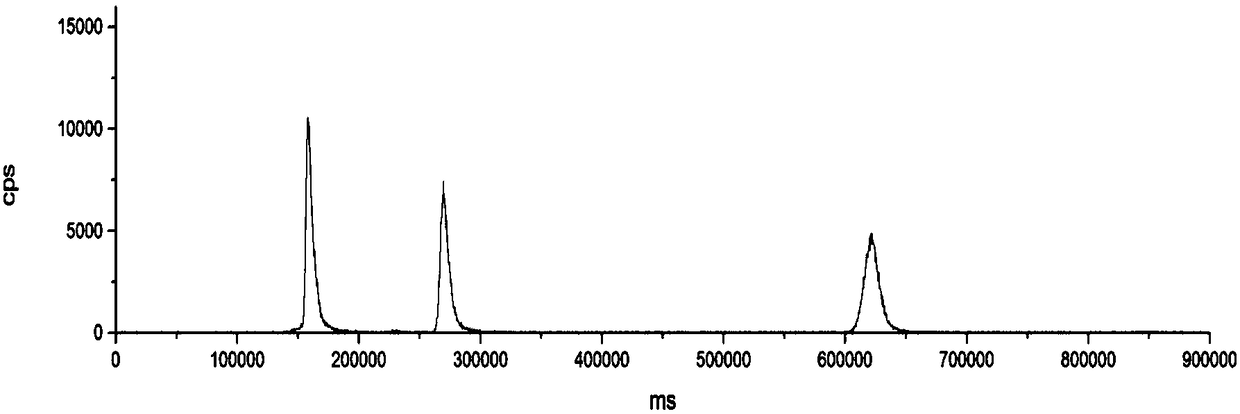

[0048] 1) Preparation of samples: Selenium-enriched peanut raw materials (total selenium content of 0.513mg / kg) were selected from the Shandong Boshan planting base funded by the National Public Welfare Industry (Agriculture) Special Project (No. 201303106); the selected selenium-enriched Peanuts are shelled and soaked in ultra-pure water for 5 minutes, uncoated, and dried to obtain selenium-enriched peanut kernels; pre-crushing selenium-enriched peanut kernels to obtain selenium-enriched peanut crushed is subjected to ultra-high pressure auxiliary solvent extraction, and selenium-enriched peanut powder is mixed with 6 The ratio of solvent to oil to liquid is 1:6g / mL, the ultra-high pressure treatment pressure is 300MPa, the extraction time is 10min, and the turbid liquid is shaken in a constant temperature water bath for 6h at 50°C, centrifuged at 4000r / min for 20min to obtain a cake for extraction, and the cake is extracted Constant temperature water bath leaching, centrifuga...

Embodiment 2

[0066] According to the steps of Example 1, only add deionized water to the selenium-enriched peanut defatted powder obtained in step 1), the ratio of material to water to liquid is 1:12g / mL, adjust the pH to 9.5 with NaOH (concentration: 1mol / L), 40°C Stir and extract in a constant temperature water bath for 1 h. 8) The extracted solution is subjected to vacuum filtration, the filtrate is collected, and the pH is adjusted to 4.7 with HCl (concentration: 1mol / L); centrifugation: 5000r / min, 15min, and the precipitate is taken; The pulverizer carries out ultrafine pulverization, and passes through a 150-mesh sieve to obtain selenium-enriched peanut protein. The result shows that the protein content of selenium-enriched peanut protein powder is 91%, and by the method detection of 3) content determination in embodiment 1, obtains that its organic selenium mainly exists with selenomethionine, and content (in terms of selenium) is 0.80 μ g / g, accounting for 76% of the total seleni...

Embodiment 3

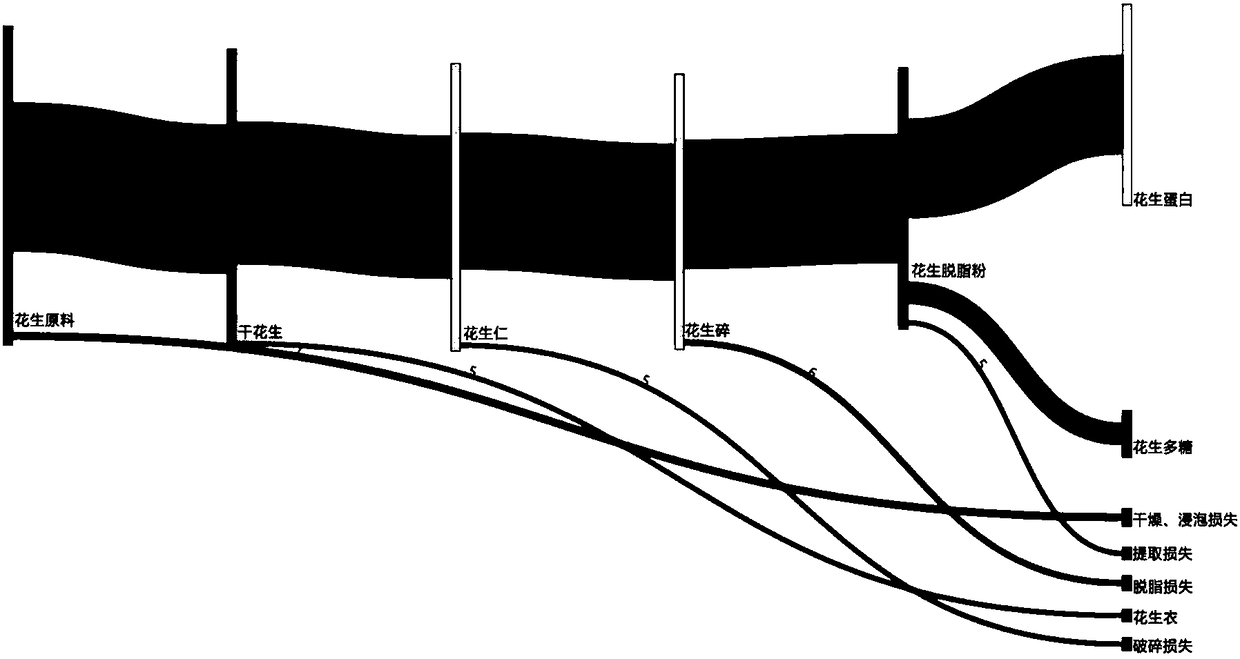

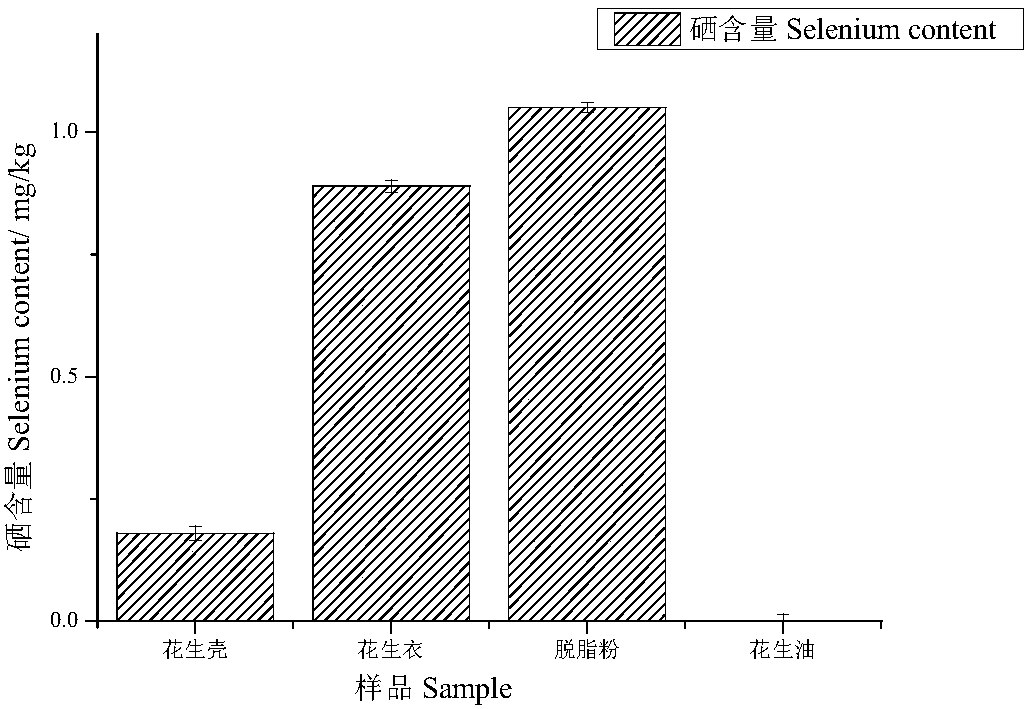

[0068] According to the step of example 1, only increase step 4) measure the loss of selenium in selenium-enriched peanut raw material to selenium-enriched peanut protein powder preparation process, as figure 2 shown, combined with image 3 The results show that the selenium in the peanut is mainly distributed in the defatted powder, the peanut oil does not contain selenium, and the peanut skin contains a certain amount of selenium, but the quality of the peanut skin is small (less than 1%), and the main components are fiber, glycosides, etc.; so the loss of selenium in the steps of removing peanut shells and peanut oil does not involve the loss of selenomethionine; the drying and crushing process belongs to thermal processing, which will cause the morphological transformation of selenomethionine and cause volatilization loss, so the selenium in the drying and crushing process Loss as selenoamino acid loss. The selenium content of every hundred selenium-enriched peanut raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com