Automatic heat shrink tubing sleeving device

A technology for covering heat-shrinkable tube and sleeve device, which is applied in the field of automatic heat-shrinkable tube device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

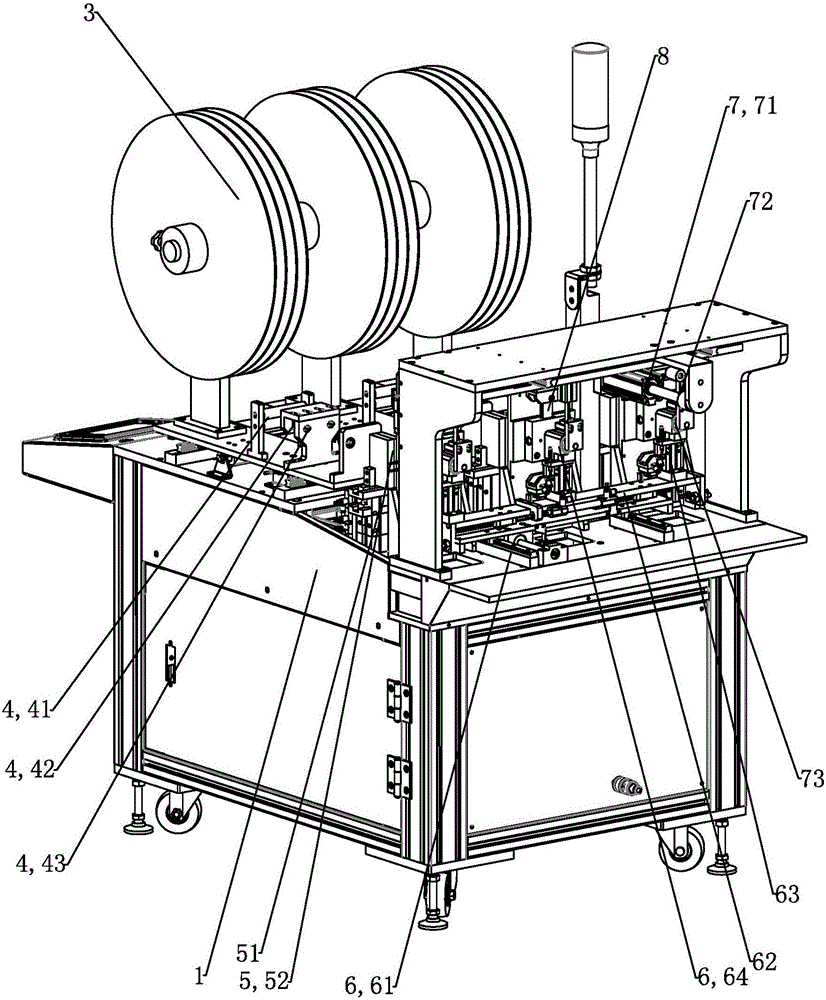

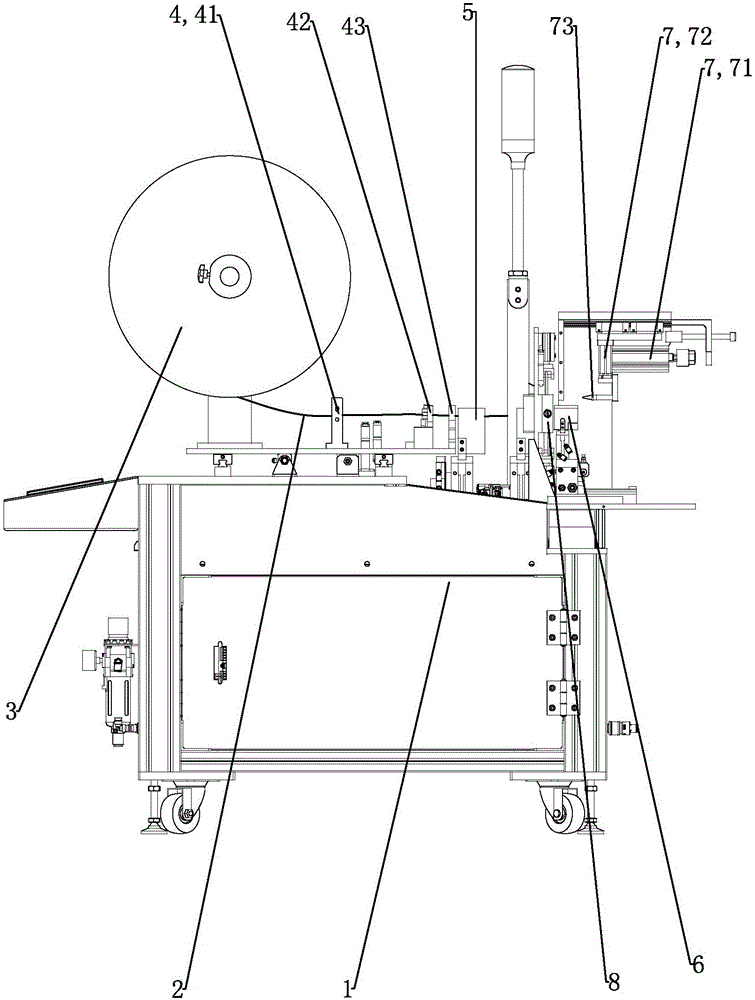

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0020] As shown in the figure, the automatic heat-shrinkable tubing device includes a frame platform 1 on which a tube coil 3 coiled with a heat-shrinkable tube 2 is arranged. A shaping device 4 for shaping the heat-shrinkable tube 2 pulled out from the tube tray 3 is provided on the frame platform 1 . A feeding mechanism 5 for feeding the heat-shrinkable tube 2 forward is provided in front of the shaping device 4 . In front of the feeding mechanism 5, there is a casing device 6 that can clamp the heat-shrinkable tube 2 and a cutter mechanism 8 that cuts the heat-shrinkable tube 2 sent to the casing device 6. On the frame platform 1 A rounding mechanism 7 that can round the heat-shrinkable tube 2 in the casing device 6 is provided on the top. In this embodiment, there are three sets of tube disk 3, shaping device 4, feeding mechanism 5, casing device 6, cutter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap