Automatic cable joining robot

A robot and cable technology, applied in the direction of connection/termination cable equipment, cable installation, cable installation device, etc., can solve the problems of cumbersome procedures, low efficiency, cable scratches, etc., to ensure personal safety, improve quality and Speed, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific implementation cases. The exemplary implementation cases and descriptions of the invention are used to explain the present invention, but not as a limitation to the present invention.

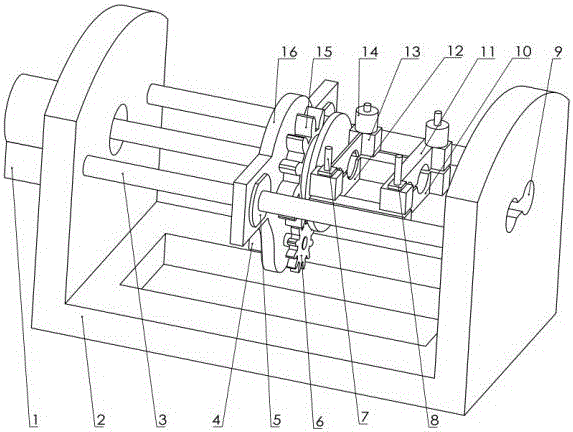

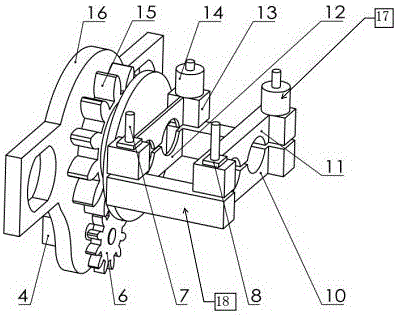

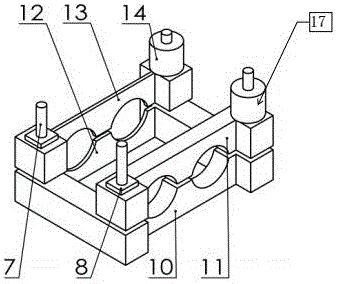

[0011] Such as Figure 1 to Figure 3 As shown, an automatic cable connecting robot includes a first electric cylinder 1, a base 2, two horizontal optical axes 3, a motor 4, two first linear bearings 5, a pinion 6, and two vertical optical axes 7 , two second linear bearings 8, wire inlet 9, cable clamp lower part 10, cable clamp upper part 11, wire stripper lower part 12, wire stripper upper part 13, second electric cylinder 14, large gear 15, sliding bracket 16, The third electric cylinder 17 and two beams 18 are characterized in that: the first electric cylinder 1 is fixed on the left side of the base 2 by bolts; Between the vertical plates, and the two optical axes are parallel to each other; the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com