High-rise building escaper and escaping method

A technology of high-rise buildings and escape devices, which is applied in the field of high-rise building escape devices and escape, and can solve problems such as potential safety hazards, inability to guarantee building power consumption, and limited use of heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

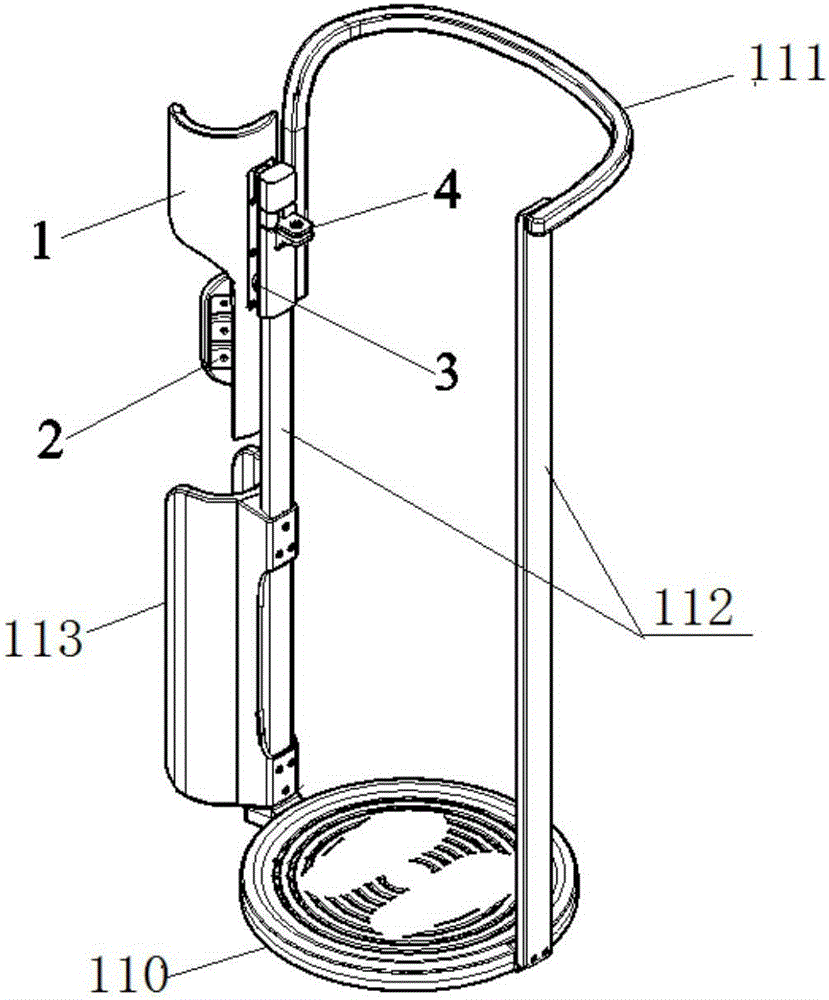

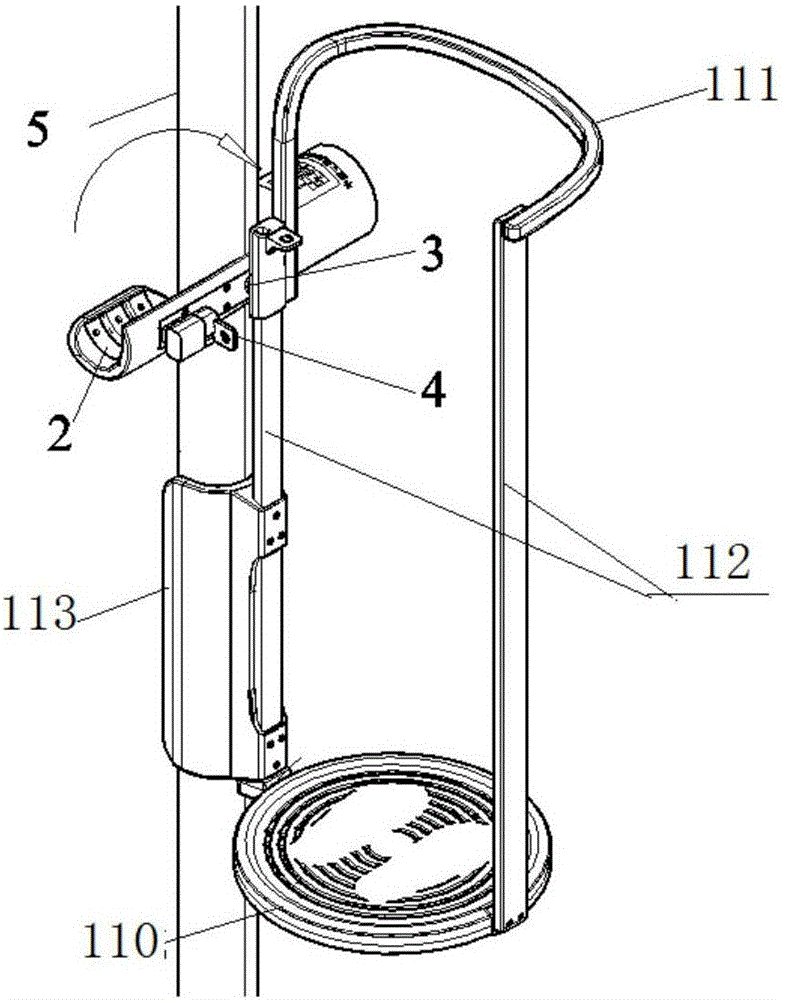

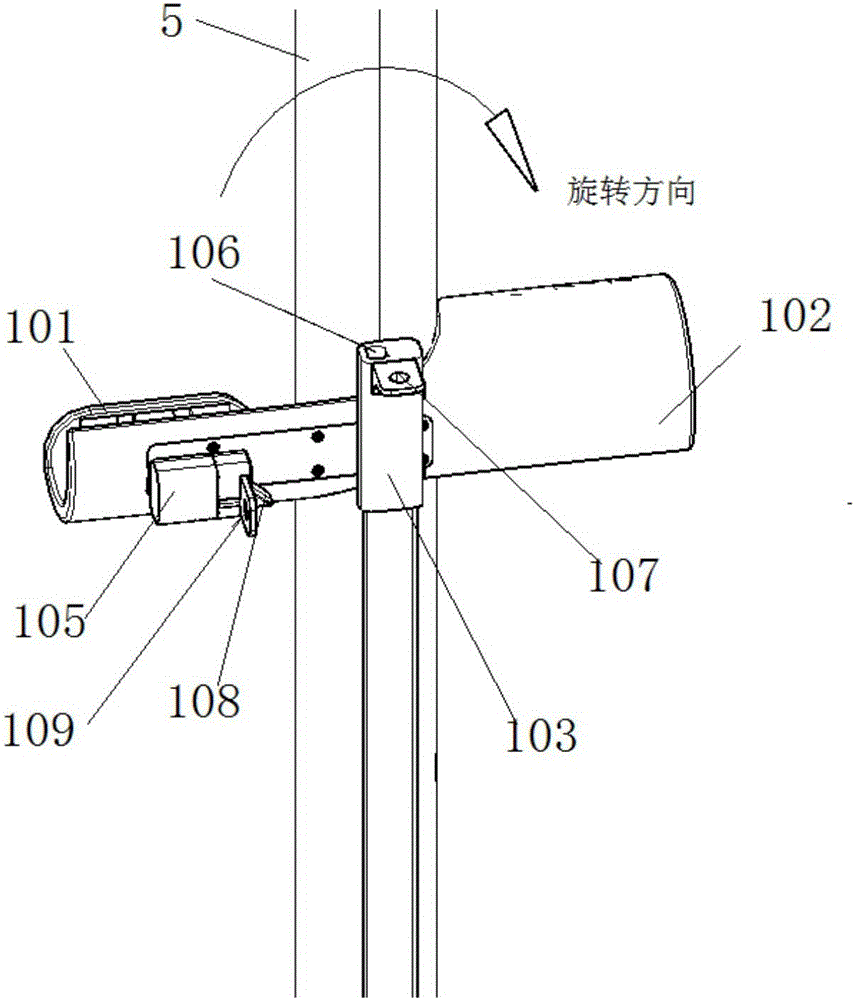

[0066] In a preferred embodiment of the present invention, as Figure 1-Figure 2d As shown, the two arc-shaped tube pieces are the first arc-shaped tube piece 101 and the second arc-shaped tube piece 102 oppositely arranged at both ends of the non-closed sleeve 1, and the first arc-shaped tube piece 101 and the second arc-shaped tube piece 101 are The arc of the cylinder piece 102 is greater than 135° and less than 180°, and the non-closed sleeve 1 is located between the first arc-shaped cylinder piece 101 and the second arc-shaped cylinder piece 102, and an arc-shaped cavity that can accommodate the non-magnetic conductive pipe 5 is provided .

[0067] In a preferred embodiment of the present invention, as Figure 1-Figure 2d As shown, the opening and closing mechanism 3 includes a fixed block 103 fixedly installed on the man-carrying device, and the fixed block 103 is connected to the non-closed sleeve 1 through a rotating shaft 104 .

[0068] In a preferred embodiment of ...

Embodiment 2

[0076] In a preferred embodiment of the present invention, as Figure 3-4b As shown, the two arc-shaped tube pieces are the third arc-shaped tube piece 201 and the fourth arc-shaped tube piece 202 which are reversely hinged through the opening and closing mechanism 3, and the third arc-shaped tube piece 201 and the fourth arc-shaped tube piece 202 can be relatively rotated under the action of the opening and closing mechanism 3 to change the opening of the locking hole.

[0077] In a preferred embodiment of the present invention, as Figure 3-4b As shown, the opening and closing mechanism 3 includes several hinges 203, and the two blades of each hinge 203 are fixedly installed on the third arc-shaped tube piece 201 and the fourth arc-shaped tube piece 202, respectively.

[0078] In a preferred embodiment of the present invention, as Figure 3-4b As shown, the locking mechanism 4 includes a first groove 204 provided at the hinge joint of the third arc-shaped tube piece 201 an...

Embodiment 3

[0085] In a preferred embodiment of the present invention, as Figure 5-6d As shown, the two arc-shaped tube pieces are the fifth arc-shaped tube piece 301 and the sixth arc-shaped tube piece 302 which are reversely hinged through the opening and closing mechanism 3, and the fifth arc-shaped tube piece 301 and the sixth arc-shaped tube piece 302 can be relatively rotated under the action of the opening and closing mechanism 3 to realize the change of the opening of the locking hole. The locking mechanism 4 includes a column 303 vertically arranged between the fifth arc-shaped cylinder piece 301 and the sixth arc-shaped cylinder piece 302 , the third locking block 304 arranged on both sides of the column 303 and the third groove 305 corresponding to the third locking block 304 on the fifth arc-shaped cylinder piece 301 and the sixth arc-shaped cylinder piece 302, when the fifth When the opening of the locking hole formed by the arc-shaped tube piece 301 and the sixth arc-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com