Micro-droplet reaction coding detection method and system

A coding detection and micro-droplet technology, which is applied to chemical instruments and methods, instruments, laboratory utensils, etc., can solve problems such as complexity and limitation of coding capabilities, and achieve the effect of large coding capacity and easy integration into lab-on-a-chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

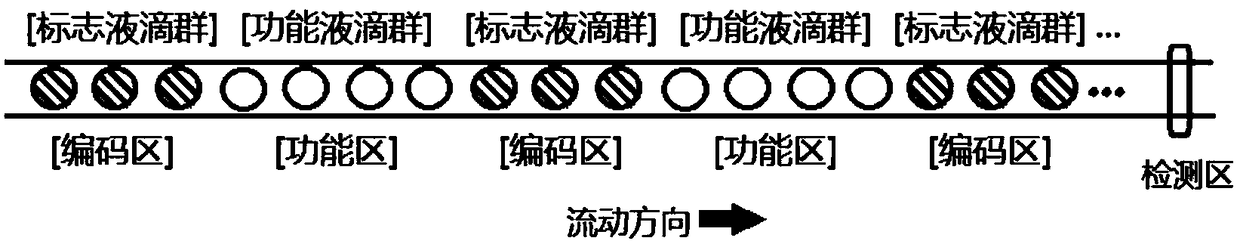

[0042] Embodiment 1 Micro-droplet reaction coding principle of the present invention

[0043] Such as figure 1 As shown, by controlling the working order of each external syringe pump, different reagents can generate micro-droplets in the microfluidic chip pipeline in a specific order, and arrange them in a queue in this order. Micro-droplets with label information become marker droplets, and the area in the queue is called the coding area; micro-droplets with biochemical reaction reagents become functional droplets, and the area in the queue is called the functional area. There is a coding region between the functional regions. The complete coding "queue" is formed by the repeating structure of the reaction region plus the coding region. When the coding "queue" enters the detection area, according to the order of sample injection and the information of each coding area, the reactants corresponding to the functional droplets contained in each functional area can be decoded. ...

Embodiment 2

[0044] Embodiment 2 Micro-droplet reaction coding detection system of the present invention

[0045] figure 2 It is a schematic diagram of the micro-droplet reaction coding detection system of the present invention, and the system is divided into four areas: sample injection area, droplet generation area, reaction area and detection area. A1, A2...An are corresponding to different injection ports, which are injected with a syringe pump. A1 is the injection port for generating marker droplets, A2, A3...An is the injection port for generating functional droplets. When the whole system is working, the order of injection is A1-A2-A1-A3 -A1...that is, the functional droplets are separated by marker droplets when injecting samples. At the intersection point connected by B1 and B2 (that is, the droplet generation area), after the droplets are generated by the water-in-oil method, they are arranged in the reaction area in a certain sequence and certain biochemical reactions occur. ...

Embodiment 3

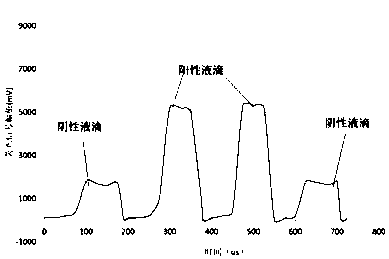

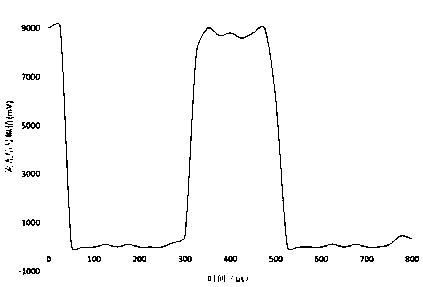

[0046] Example 3 Using high fluorescence intensity as the encoding of the characteristics of the marker droplet to realize multi-site gene detection

[0047] Step 1 Liquid reagent injection control

[0048] The encoding method proposed by the present invention requires droplets to form a "queue" in which the coding area and the functional area are interlaced in the pipeline, so there are certain requirements for the order of different reagent injections, and the order of injection is controlled by the external syringe pump. The order of work is determined.

[0049] figure 2 The syringe pump shown is a high-precision syringe pump (Harvard Apparatus, PHD Ultra). Each syringe pump is fixed with a 1ml syringe and connected to the chip inlet through a Teflon tube. Each syringe is loaded with different reagents, among which the syringes corresponding to B1 and B2 are loaded with mineral oil for subsequent droplet generation; the syringe corresponding to A1 is loaded with M at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com