Magnetically-braked noise-reducing high-pressure water rotating nozzle

A technology of magnetic braking and rotating nozzles, applied in the direction of spraying devices and spraying devices with movable outlets, can solve the problems of large-scale application of unfavorable products, health hazards of operators, high production costs, etc., and achieve simple structure and good cleaning effect , The effect of improving the striking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

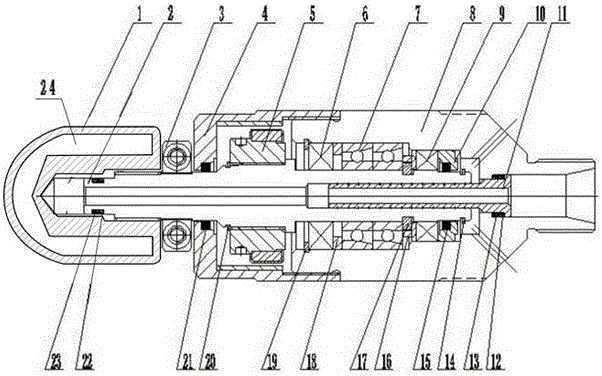

[0013] Such as figure 1 A magnetically braked high-pressure water noise-reducing rotary sprinkler head is shown, including a rotary head 1 with an eccentric hole drilled thereon, a rotary shaft protective sleeve 3, a connecting magnetic assembly 5, a rotary shaft 2 assembly, a casing 8, and a rotary head 1 It is connected to the front end of the rotating shaft 2 assembly through threads, the rotating head is a hollow structure, the outer layer is made of titanium alloy material, and the middle layer is rubber noise-absorbing material 24; A linear braking part 4 is provided, and the linear braking part is fixedly connected with the casing 8 through threads, and an annular stepped step is arranged inside the casing, and the rotating shaft assembly is installed in the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com