High pressure water self rotation shower nozzle

A self-rotating, high-pressure water technology, used in spraying devices, spraying devices with movable outlets, etc., can solve the problems of difficult to guarantee raw materials, high machining accuracy of parts, lack of professionals, etc., to increase the striking force and prolong the service life. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

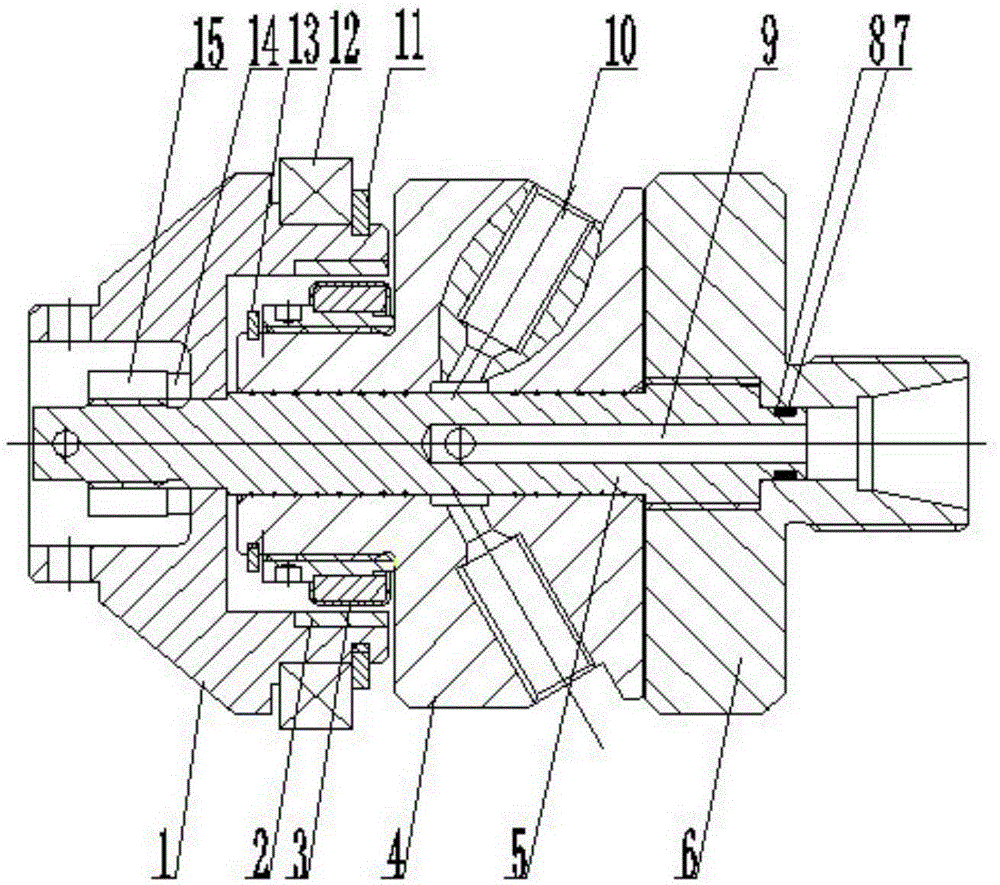

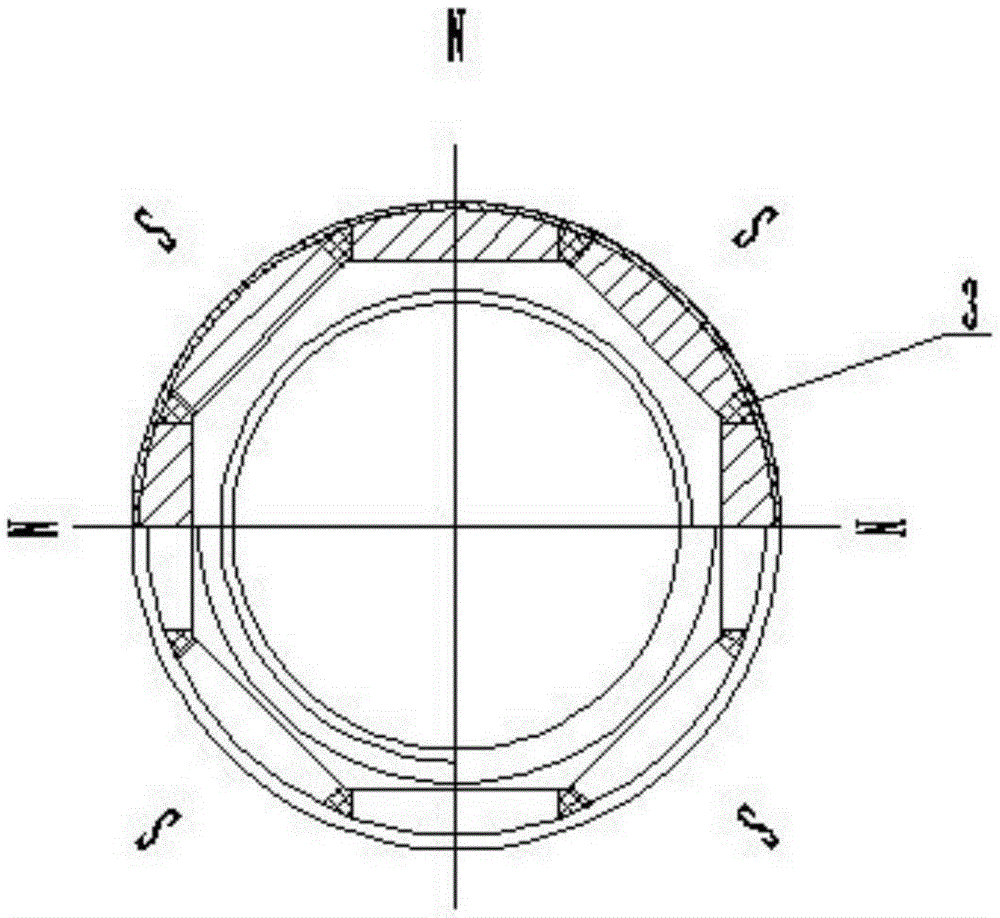

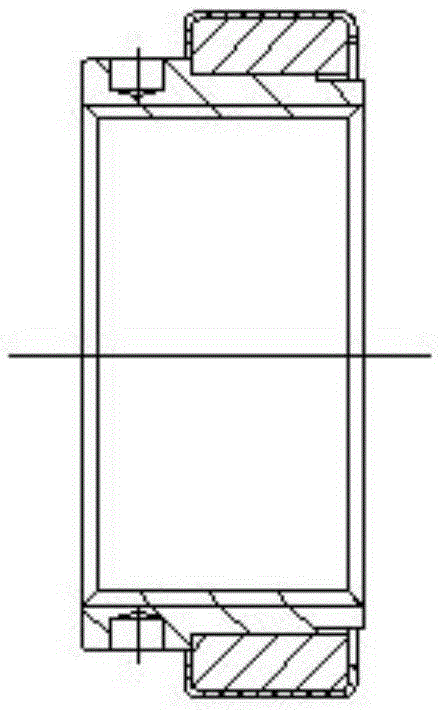

[0020] Such as figure 1 As shown, the high-pressure water self-rotating nozzle provided by the present invention includes a water inlet joint 6, and the water inlet joint 6 is fixedly connected with the sealing shaft 5 through threads, and the sealing shaft 5 penetrates into the rotating housing from the rear end of the rotating housing 4, and the rotating housing 4 and There is a gap between the sealing shafts 5, and several rows of annular grooves are processed on the outside of the sealing shafts 5 (see Figure 4 and Figure 5 ), the static sealing part between the sealing shaft 5 and the inner hole of the water inlet joint 6 adopts a sealing structure composed of an "O"-shaped rubber sealing ring 7 and a plastic sealing retaining ring 8, and the front end of the rotating housing 4 is threaded and connected to the magnetic assembly 3 Fixed connection, the rotating housing 4 is drilled with a spray hole 10 eccentric to the central axis of the rotating housing 4, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com