A method of using a new material graphene mixture in electrical maintenance

A technology of graphene and mixed liquid, which is applied to the surface coating liquid device, conductive paint, liquid injection device, etc., to achieve the effect of easy edge finding, convenient use, and improved conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

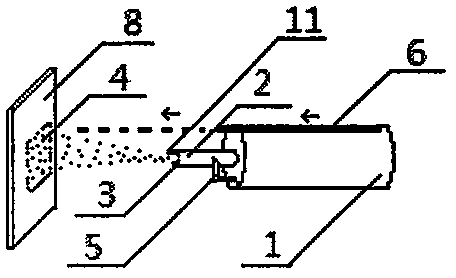

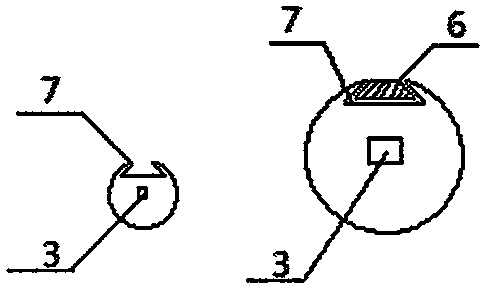

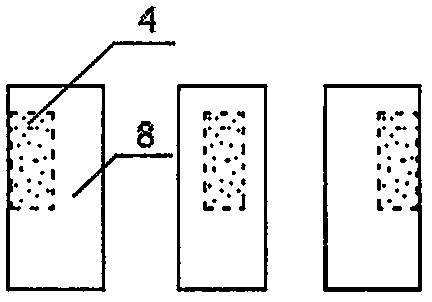

[0040] exist figure 1 In the shown embodiment, a new material graphene mixed liquid automatic spraying device includes a device body 1, a connecting body 2, a nozzle 3, a handle 5, a support rod 6, a busbar 8, and a nozzle baffle 11. The device body 1 is provided with a connecting body 2, and the front end of the connecting body 2 is provided with a nozzle 3, and the shape of the nozzle 3 is a cube, a cuboid, or a combination of a cube and a circle, or a cuboid and a circle. combination, the surface shape of the object after the nozzle 3 sprays the object is a rectangle 4 (such as figure 1 4). The front end side of the nozzle 3 is provided with a nozzle baffle 11, the nozzle 3 is fixedly connected with the nozzle baffle 11, the handle 5 is arranged on the connecting body 2, and the graphene mixture is automatically sprayed by pressing the handle 5. out the liquid. The groove 7 is arranged through the side of the device body 1 , and the support rod 6 can be placed in the gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com